LSR For Miscellaneous Pieces (Coating)

Applications  Features Rapid vulcanization, good dimensional stability and processability; Non-toxic and safe, food grade; High tear strength, non-yellowing; Approvals

Features Rapid vulcanization, good dimensional stability and processability; Non-toxic and safe, food grade; High tear strength, non-yellowing; Approvals

Appearance: Translucent Viscosity: 2W-3W Hardness (Shore A): 20 Density (g/cm3): 1.06 Tensile strength (Mpa): 6 Elongation (%): 700 Tear strength (K N/m): 15 Model: HT-T7300A/B

Appearance: Translucent Viscosity: 2W-3W Hardness (Shore A): 30 Density (g/cm3): 1.08 Tensile strength (Mpa): 6 Elongation (%): 700 Tear strength (K N/m): 15 Model: HT-T7400A/B

Appearance: Translucent Viscosity: 2W-3W Hardness (Shore A): 40 Density (g/cm3): 1.1 Tensile strength (Mpa): 7 Elongation (%): 650 Tear strength (K N/m): 20 Model: HT-T7500A/B

Appearance: Translucent Viscosity: 2W-3W Hardness (Shore A): 50 Density (g/cm3): 1.12 Tensile strength (Mpa): 7 Elongation (%): 600 Tear strength (K N/m): 25 Model: HT-T7600A/B

Appearance: Translucent Viscosity: 2W-3W Hardness (Shore A): 60 Density (g/cm3): 1.12 Tensile strength (Mpa): 7 Elongation (%): 450 Tear strength (K N/m): 25 Model: HT-T7700A/B

Appearance: Translucent Viscosity: 2W-3W Hardness (Shore A): 70 Density (g/cm3): 1.14 Tensile strength (Mpa): 8 Elongation (%): 400 Tear strength (K N/m): 20 Model: HT-T7800A/B

Appearance: Translucent Viscosity: 2W-3W Hardness (Shore A): 80 Density (g/cm3): 1.14 Tensile strength (Mpa): 7 Elongation (%): 260 Tear strength (K N/m): 15

This liquid silicone rubber (LSR) can be used as coating materials for electrical and electronic components, sponge sheets and fiberglass cloth.

ROHS, REACH, FDA, CA65, EN71-3, EN14372, PAHS, PFOA, CPSIA, Dimethyl Cyclosiloxane, etc.

TestRheometer test, 120℃, 5min

Technical Data Model: HT-T7200A/BAppearance: Translucent Viscosity: 2W-3W Hardness (Shore A): 20 Density (g/cm3): 1.06 Tensile strength (Mpa): 6 Elongation (%): 700 Tear strength (K N/m): 15 Model: HT-T7300A/B

Appearance: Translucent Viscosity: 2W-3W Hardness (Shore A): 30 Density (g/cm3): 1.08 Tensile strength (Mpa): 6 Elongation (%): 700 Tear strength (K N/m): 15 Model: HT-T7400A/B

Appearance: Translucent Viscosity: 2W-3W Hardness (Shore A): 40 Density (g/cm3): 1.1 Tensile strength (Mpa): 7 Elongation (%): 650 Tear strength (K N/m): 20 Model: HT-T7500A/B

Appearance: Translucent Viscosity: 2W-3W Hardness (Shore A): 50 Density (g/cm3): 1.12 Tensile strength (Mpa): 7 Elongation (%): 600 Tear strength (K N/m): 25 Model: HT-T7600A/B

Appearance: Translucent Viscosity: 2W-3W Hardness (Shore A): 60 Density (g/cm3): 1.12 Tensile strength (Mpa): 7 Elongation (%): 450 Tear strength (K N/m): 25 Model: HT-T7700A/B

Appearance: Translucent Viscosity: 2W-3W Hardness (Shore A): 70 Density (g/cm3): 1.14 Tensile strength (Mpa): 8 Elongation (%): 400 Tear strength (K N/m): 20 Model: HT-T7800A/B

Appearance: Translucent Viscosity: 2W-3W Hardness (Shore A): 80 Density (g/cm3): 1.14 Tensile strength (Mpa): 7 Elongation (%): 260 Tear strength (K N/m): 15

Scan QR to Read

Links:https://globefindpro.com/products/1438.html

Links:https://globefindpro.com/products/1438.html

Recommended Products

-

CDM/CDMF Series Vertical Multistage Pump

CDM/CDMF Series Vertical Multistage Pump

-

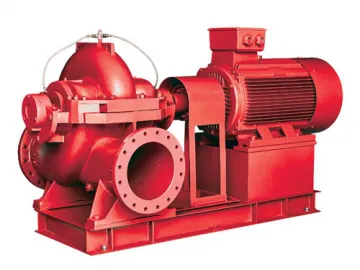

PSCMF series Double Suction Fire Pump

PSCMF series Double Suction Fire Pump

-

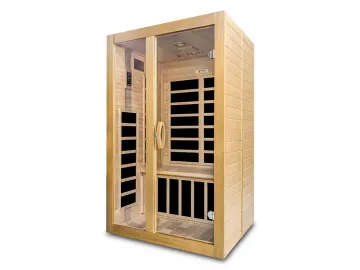

2-Person Infrared Sauna, DX-6206

2-Person Infrared Sauna, DX-6206

-

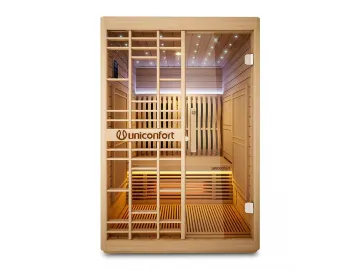

3-Person Infrared Sauna, DX-6354

3-Person Infrared Sauna, DX-6354

-

4-Person Infrared Sauna, DX-6602

4-Person Infrared Sauna, DX-6602

-

2-Person Infrared Sauna, DX-6209

2-Person Infrared Sauna, DX-6209

-

Hybrid Outdoor Sauna, DX-7331

Hybrid Outdoor Sauna, DX-7331

-

PVT series Fire Pump Set

PVT series Fire Pump Set

-

PVF Series Vertical Multistage Pump

PVF Series Vertical Multistage Pump

-

1-Person Half Body Sauna, DX-6158

1-Person Half Body Sauna, DX-6158

-

YC Series Single Phase Asynchronous Motor with Starting Capacitor

YC Series Single Phase Asynchronous Motor with Starting Capacitor

-

Silicone Rubber for LED Extrusion

Silicone Rubber for LED Extrusion

Hot Products