Metal shredder

3E metal shredder is extensively applicable to the recycling of wasted metals in many industries, such as scrap metal, thin-walled disposed steel, vehicle body, engine house, aluminum profile, baling aluminum, oil barrels, light metal, pop cans, aluminium skimmings, electronic wastes and more. The shredded materials can be recycled directly or further refined according to the needs. It uses Siemens microcomputer control system to protect the machine overload and interference. The metal shredder has the functions of starting, stopping and automatic reverse gear sensor. 3E metal shredder has low energy consumption, high efficiency, even discharge, smooth operation, low noise, simple operation and easy maintenance which can also set the discharge size on the basis of needs of customers.

Structure Charts

Technical Specifications of Medium Two shaft shredder

| Model Item | GL3280 | GL32100 | GL32120 | GL40100 | GL40130 | GL40160 | GL50130 | GL50180 | |

| Dimension L/W/H (mm) | 3250*1346*2275 | 3450*1346*2275 | 3650*1946*2275 | 4074*1770*3465 | 4374*1770*3765 | 4674×1770×3765 | 4670*1866*3905 | 5170×1866×3905 | |

| Cutting chamber C/D (mm) | 812×736 | 1012×736 | 1212*736 | 1024*948 | 1324*948 | 1624×948 | 1312*1206 | 1812×1206 | |

| Rotor Diameter (mm) | φ430 | φ430 | φ430 | φ514 | φ514 | φ514 | φ650 | φ650 | |

| Blade quantity (pcs) | 20 | 25 | 30 | 20 | 26 | 32 | 26 | 36 | |

| Blade thickness (mm) | 40 | 40 | 40 | 50 | 50 | 50 | 50 | 50 | |

| Main Motor Power (kw) | 15+15 | 22+22 | 22+22 | 37+37 | 45+45 | 45+45 | 55+55 | 55+55 | |

| Weight (kg) | 3700 | 4100 | 4500 | 6500 | 8700 | 9200 | 12800 | 13600 | |

| Model Item | GL61180 | GLD61210 | GLD80210 | |

| Dimension L/W/H (mm) | 5404×2404×3746 | 5297×2714×3537 | 7110×2911×4240 | |

| Cutting chamber C/D (mm) | 1812×1490 | 2112×1510 | 2108×1910 | |

| Rotor Diameter (mm) | φ800 | φ800 | φ980 | |

| Blade quantity (pcs) | 24 | |||

| Blade thickness (mm) | 75 | 75-750 | 100-200 | |

| Main Motor Power (kw) | 75+75 | 180-360 | 266-500 | |

| Weight (kg) | 20200 | 23200 | 36500 | |

Hydraulic Feeder

3E metal shredder can be set up a piece of material pressing equipment to press the material to the cutter by hydraulic pressure when handling hollow or loose materials. So it can improve the shredding efficiency greatly.

Hydraulic Drive

3E metal shredder can adopt hydraulic drive with high speed and large torque to replace the motor drive and set positive and negative rotation to shred more stably and reduce the mechanical damage.

Planet-gear Speed Reducer

Planet-gear speed reducer has compact structure, small volume, large transmission power and high capacity, so it has the characteristics of high transmission efficiency, stable operation, high impact and vibration resistance.

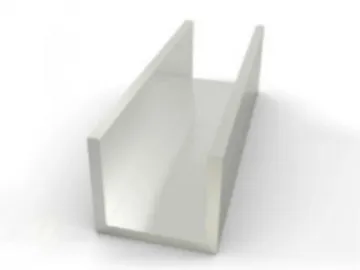

Blade

3E metal shredder can choose different types of blades on the basis of different materials and shapes of the shredded materials.

The thickness of the blade is optional according to the particle size after shredding the material. The standard blade of the metal shredder is double-claw blade. If you need single or multi-claw blade, please contact our sales representative.3E metal shredder can choose different types of rotors on the basis of different types of materials and the processing needs after shredding.

Links:https://globefindpro.com/products/14929.html