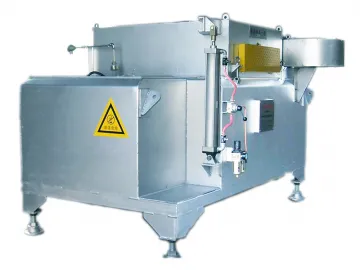

Continuous Mesh-belt Furnace

Heating and Melting Equipment (Heating, Quenching, Carburizing, Carbonitriding and Tempering)

Features Continuous production, stepless speed regulation, easy process parameter control Smooth mesh belt running with no deformation Muffle furnace with an excellent sealing performance, controllable gas consumption saves energy

Features Continuous production, stepless speed regulation, easy process parameter control Smooth mesh belt running with no deformation Muffle furnace with an excellent sealing performance, controllable gas consumption saves energy

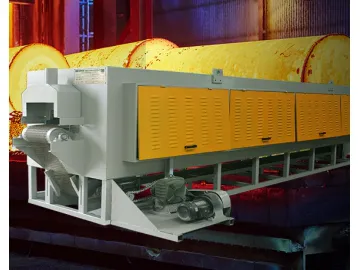

Different preparation atmospheres or instillation atmospheres are used for bright quenching, thin layer carburizing or carbonitriding; Quenching tanks with optional quenching media including water, oil and molten salt are available for a variety of processes Overall process control with high automation accuracy PID temperature adjustment with high control precision Clean working environment. Working principle Water, oil or molten salt are chosen as the quenching medium inside the quenching tank according to different steel grades. The mesh belt furnace is used for tempering below 650 ℃. Most of them are paired with the 1st two furnaces as continuous production units. Traditionally, there is a mesh belt cleaning machine located between the quenching furnace and the tempering furnace inside the mesh-belt furnace, though this is optional upon request. A washing machine and feeding machine can be equipped before the quenching furnace, and a cooling tank can be installed after the tempering furnace. Parameters

As a leading manufacturer of continuous mesh belt furnaces (also known as conveyor belt furnaces), our mesh-belt furnaces are customized according to special working conditions and parameters, making them the right equipment for quenching, carburizing, carbonitriding and subsequent tempering during medium temperature heating. The conveyor belt furnaces are also used for bright quenching, thin-layer carburizing and carbonitriding in shielding gases for mass-produced small and medium sized parts such as fasteners, chains, bearings, small weapons, hardware tools, elastic components, sewing machines, bicycle parts, automobile parts, motorcycle parts and more.

Different preparation atmospheres or instillation atmospheres are used for bright quenching, thin layer carburizing or carbonitriding; Quenching tanks with optional quenching media including water, oil and molten salt are available for a variety of processes Overall process control with high automation accuracy PID temperature adjustment with high control precision Clean working environment. Working principle Water, oil or molten salt are chosen as the quenching medium inside the quenching tank according to different steel grades. The mesh belt furnace is used for tempering below 650 ℃. Most of them are paired with the 1st two furnaces as continuous production units. Traditionally, there is a mesh belt cleaning machine located between the quenching furnace and the tempering furnace inside the mesh-belt furnace, though this is optional upon request. A washing machine and feeding machine can be equipped before the quenching furnace, and a cooling tank can be installed after the tempering furnace. Parameters

| Model | Rated power(KW) | Rated voltage (V) | Max. Operating temperature (℃) | Working area dimensions (mm) | Belt speed (mm/min) | Gas consumption (m3/h) | Production rate (kg/h)) | ||

| Length | Width | Height | |||||||

| RCWA-20-3/6 | 20 | 380 | 650/350 | 2500 | 300/350 | 70 | 17~180 | 2.5 | 40 |

| RCWA-30-3/6 | 30 | 380 | 650/350 | 4000/3600 | 350/400 | 70 | 17~180 | 3 | 60 |

| RCWA-40/50-3/6 | 40/45 | 380 | 650/350 | 4500/4000 | 600 | 80 | 17~180 | 3.5 | 120/150 |

| RCWA-60-3/6 | 60 | 380 | 650/350 | 5000/4300 | 600/800 | 100 | 17~180 | 4 | 200 |

| RCWA-75-3/6 | 75 | 380 | 650/350 | 6000/5000 | 800 | 100 | 17~180 | 5 | 250 |

| RCWA-90-3/6 | 90 | 380 | 650 | 6000 | 800 | 100 | 17~180 | 6 | 300 |

| RCWA-120-3/6 | 120 | 380 | 650 | 8500 | 1000 | 120 | 17~180 | 8 | 500 |

| RCWA-180-3/6 | 180 | 380 | 650 | 10000 | 1000 | 120 | 17~180 | 10 | 800 |

| RCWA-240-3/6 | 240 | 380 | 650 | 14000 | 1000 | 120 | 17~180 | 12 | 100 |

Scan QR to Read

Links:https://globefindpro.com/products/18683.html

Links:https://globefindpro.com/products/18683.html

Recommended Products

-

Melting and Holding Furnace for Non-ferrous Metals(Aluminum, Magnesium and Zinc)

Melting and Holding Furnace for Non-ferrous Metals(Aluminum, Magnesium and Zinc)

-

Zinc Melting Furnace

Zinc Melting Furnace

-

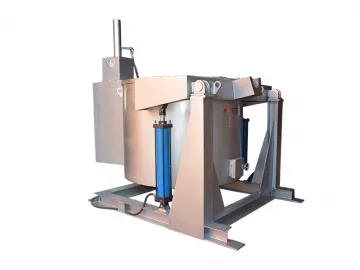

Pouring Ladles for Magnesium Casting

Pouring Ladles for Magnesium Casting

-

Non-crucible Furnace

Non-crucible Furnace

-

Gas or Oil Fired Crucible Furnace

Gas or Oil Fired Crucible Furnace

-

Paper Medical Tape

Paper Medical Tape

-

Aluminum Holding Furnace

Aluminum Holding Furnace

-

Electric Holding Furnace

Electric Holding Furnace

-

Heat Treatment Furnace

Heat Treatment Furnace

-

Tilting Rotary Crucible Furnaces

Tilting Rotary Crucible Furnaces

-

Reverberatory Furnaces

Reverberatory Furnaces

-

Gas Fired Tilting Furnace

Gas Fired Tilting Furnace

Hot Products