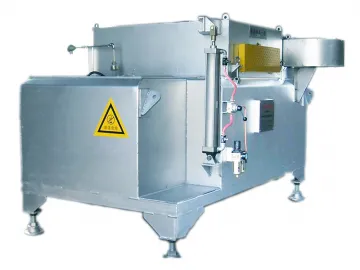

Electric Holding Furnace

Heating and Melting Equipment Introduction

Features

The material poured in the molten bath will not stick to the aluminum, effectively controlling molten metal penetration to the material.

The electric holding furnace is equipped with an advanced control system, digital display, and control instruments such as AI temperature control.

With a uniform internal temperature, the furnace has an outstanding heat preservation effect, allowing molten aluminum to remain in the molten state after 8 hours of power failure. The furnace casing temperature is controlled below 60℃, ensuring heat leakage is fully controlled to ensure an energy-saving and safe melting process.

The heating system is powered using electric energy with no noise, no pollution and the melting accuracy up to 99%, which meets the requirements of international environmental technical standards for production equipment.

An automatic thermostat with a PID system can automatically control the power output upon customer request, thus saving energy.

Parameters

The electric holding furnace is an energy-saving and eco-friendly device for melting and holding aluminum alloy, making it suitable for melting and holding non-ferrous metals around the die casting machine.

Features

The material poured in the molten bath will not stick to the aluminum, effectively controlling molten metal penetration to the material.

The electric holding furnace is equipped with an advanced control system, digital display, and control instruments such as AI temperature control.

With a uniform internal temperature, the furnace has an outstanding heat preservation effect, allowing molten aluminum to remain in the molten state after 8 hours of power failure. The furnace casing temperature is controlled below 60℃, ensuring heat leakage is fully controlled to ensure an energy-saving and safe melting process.

The heating system is powered using electric energy with no noise, no pollution and the melting accuracy up to 99%, which meets the requirements of international environmental technical standards for production equipment.

An automatic thermostat with a PID system can automatically control the power output upon customer request, thus saving energy.

Parameters

| Model | Melting capacity (kg/h) | Molten bath capacity (kg) | Power consumption (kw/h) | Adaptive Die Cast Machine |

| HX-40 | 40 | 200 | 15-17 | 125-160T |

| HX80 | 80 | 400 | 30-35 | 160-200T |

| HX-100 | 100 | 500 | 40-42 | 200-280T |

| HX120 | 120 | 600 | 48-50 | 280-400T |

Scan QR to Read

Links:https://globefindpro.com/products/18681.html

Links:https://globefindpro.com/products/18681.html

Recommended Products

-

Aluminum Holding Furnace

Aluminum Holding Furnace

-

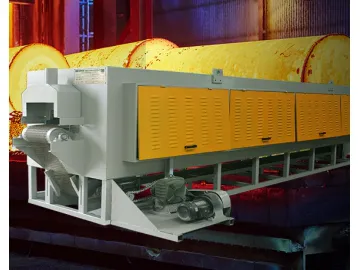

Continuous Mesh-belt Furnace

Continuous Mesh-belt Furnace

-

Melting and Holding Furnace for Non-ferrous Metals(Aluminum, Magnesium and Zinc)

Melting and Holding Furnace for Non-ferrous Metals(Aluminum, Magnesium and Zinc)

-

Zinc Melting Furnace

Zinc Melting Furnace

-

Pouring Ladles for Magnesium Casting

Pouring Ladles for Magnesium Casting

-

Non-crucible Furnace

Non-crucible Furnace

-

Heat Treatment Furnace

Heat Treatment Furnace

-

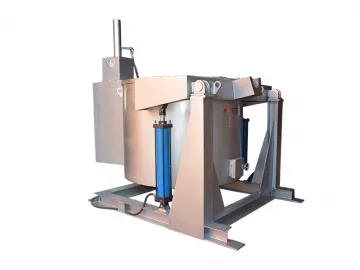

Tilting Rotary Crucible Furnaces

Tilting Rotary Crucible Furnaces

-

Reverberatory Furnaces

Reverberatory Furnaces

-

Gas Fired Tilting Furnace

Gas Fired Tilting Furnace

-

Printed, Self-engaging Hook and Loop Fastener

Printed, Self-engaging Hook and Loop Fastener

-

Electric Melting and Holding Furnace

Electric Melting and Holding Furnace

Hot Products