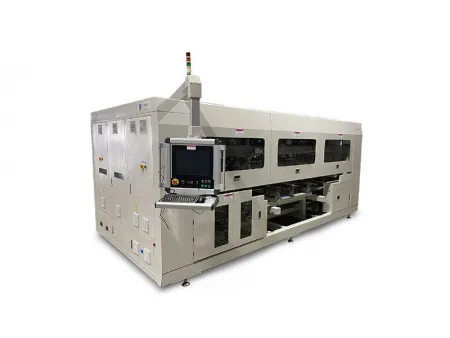

Automatic Bussing Machine

Used for automatic interconnection of PV cell strings  Technical Parameters

Technical Parameters

Features

Separating the cell string from the glass, and grabbing the cell string in the air with its head, middle and tail exposed to be soldered with busbar at a certain height;

Bypass busbar for 5 strings of 1/3 210mm cells;

Rolling bus belt supply and U and L-shaped lead bending for different processing needs;

The function of bus belt drilling can be turned on or off as customer needs;

The assembly line in front of the welding machine ensures the accurate positioning of solar panels to improve soldering quality.

An automatic bussing machine adopts induction welding and can be applied to 5BB-12BB solar cells of 156-210mm. The soldering precision is high. The busbar overlap area exceeds 80%, and the deviation is ±1mm. The bussing machine features a small size and is suitable for safe and stable production of various solar strings. The soldering stringer is an indispensible machine for solar string production.

| Item | Parameters |

| Cell type | 156mm-210mm/5BB-12BB |

| Panel size | 2,500mm*1,400mm |

| Busbar specification | Roll feeding and automatic cutting; thickness 0.18-0.45mm; Width 4mm, 5mm, 6mm, 8mm; roller weight≤13kg |

| Cycle time | 20s for conventional welding; 25s for bypass welding |

| Breakage rate | < 0.2% |

| Soldering method | Induction soldering |

| Lead busbar angle and deviation | 90°; deviation≤2° |

| Busbar overlap area | ≥80%, and the deviation is within ± 1 mm |

| Overlap deviation of bypass bus belt | ±1mm |

| Secondary string layup accuracy | ±0.25mm |

| Utilization rate | ≥98% |

| Overall dimensions (L*W*H) | 4,930*4,613*2,641mm |

| Voltage | 3 phase 5 wire 380V, 50/60Hz |

| Power | Average 22kW; Peak 30kW |

| Air pressure | 0.6-0.8MPa 2.0m3/min |

Features

Separating the cell string from the glass, and grabbing the cell string in the air with its head, middle and tail exposed to be soldered with busbar at a certain height;

Bypass busbar for 5 strings of 1/3 210mm cells;

Rolling bus belt supply and U and L-shaped lead bending for different processing needs;

The function of bus belt drilling can be turned on or off as customer needs;

The assembly line in front of the welding machine ensures the accurate positioning of solar panels to improve soldering quality.

Scan QR to Read

Links:https://globefindpro.com/products/206.html

Links:https://globefindpro.com/products/206.html

Recommended Products

-

Double Layer & Triple Chamber Laminator

Double Layer & Triple Chamber Laminator

-

Automatic Glass Loading Machine

Automatic Glass Loading Machine

-

EVA Cutting and Layup Machine

EVA Cutting and Layup Machine

-

Robot String Layup Machine

Robot String Layup Machine

-

Automatic J-Box Potting Machine

Automatic J-Box Potting Machine

-

Automatic Framing Machine

Automatic Framing Machine

-

Solar simulator for measuring the performance of PV module

Solar simulator for measuring the performance of PV module

-

Automatic Corner Grinding Machine

Automatic Corner Grinding Machine

-

Automatic Corner Protector Inserting Machine

Automatic Corner Protector Inserting Machine

-

Vertical Sorting Machine

Vertical Sorting Machine

-

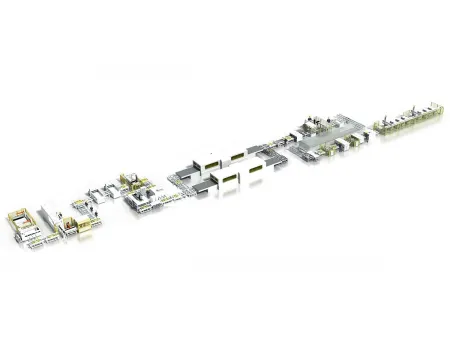

300MW Solar Panel Production Line

300MW Solar Panel Production Line

-

100MW Solar Panel Production Line

100MW Solar Panel Production Line

Hot Products