Calcination Unit

Calcination is an important part of gypsum processing, quality of calcination directly determines quality of the final product.

Gypsum powder enters the fluidized gypsum boiling furnace for calcination after being pre-dried.

Discharge temperature of calcination process is 150-160 °C, by adjusting boiling furnace internal temperature, etc.,

parameters of the finished building gypsum can be adjusted to meet different requirements.

New-Type Boiling Furnace Calcination Features of Calcination System:Low-temperature heat source is applied, to prevent gypsum from getting over heated, by controlling discharge temperature, except a small amount of dihydrate and anhydrite gypsum, the major containment of the finished product is hemihydrate gypsum, which is an ideal condition with stable physical performance. Simple structure, uneasy to damage; vertical design with compact size, room-saving. High qualified products. Energy saving, over 95% high thermal efficiency, very low energy loss. Eco-friendly, both built-in dust collector and bag type dust collector are applied. Heat Source:

Coal and gas (light oil) burns serve as heat source, hot air as heat exchange medium, thermal efficient > 85%; preheating utilization system is applied, leading exhaust gas to the outlet position, getting it mixed with the high temperature flue gas stroke, to effectively save energy.

Scan QR to Read

Links:https://globefindpro.com/products/21056.html

Links:https://globefindpro.com/products/21056.html

Recommended Products

-

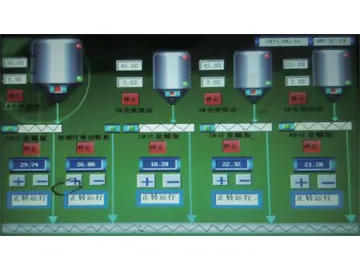

Automation and Control System

Automation and Control System

-

Hospital Modular Operating Theater

Hospital Modular Operating Theater

-

Cleanroom Solution

Cleanroom Solution

-

Pass Box, Pass-through Chamber

Pass Box, Pass-through Chamber

-

Pharmaceutical Industry

Pharmaceutical Industry

-

Grinding and Separation Units

Grinding and Separation Units

-

Studded Leather Belt, Rivet Belt

Studded Leather Belt, Rivet Belt

-

Cow Suede Leather Belt

Cow Suede Leather Belt

-

Cardboard Preparation and Forming Unit of Plasterboard Production Line

Cardboard Preparation and Forming Unit of Plasterboard Production Line

-

XHD-80/120/80*2350 Fully Automatic Extrusion Stretch Film Line

XHD-80/120/80*2350 Fully Automatic Extrusion Stretch Film Line

-

Embossed Leather Belt

Embossed Leather Belt

-

Gypsum Board Sheathing

Gypsum Board Sheathing

Hot Products