Back Part Molding Machine With 2 Hot and 2 Cold Stations

Professional footwear machinery manufacturer and complete footwear manufacturing solution provider  Features

Features

During operation, users can set the machine’s precise motion to obtain a better heel molding effect.

The upper mold’s air bag is made of a special material and a protective leather cover to prevent shoe scratching and obtain a better molding effect.

The die casting time can be set according to the customer's actual requirements.

The cold and hot die feature the same structure, making operation easier and improves efficiency.

The molding machine is equipped with a rearview mirror to facilitate accurate vamp location positioning. Specification

This back part molding machine features two hot and two cold stations. It is used to mold heel counters and sides. In order to facilitate shoe mold replacement, the upper machine mold is equipped with air bags, making it unnecessary to change the mold.

During operation, users can set the machine’s precise motion to obtain a better heel molding effect.

The upper mold’s air bag is made of a special material and a protective leather cover to prevent shoe scratching and obtain a better molding effect.

The die casting time can be set according to the customer's actual requirements.

The cold and hot die feature the same structure, making operation easier and improves efficiency.

The molding machine is equipped with a rearview mirror to facilitate accurate vamp location positioning. Specification

Machine size:1500*900*2050mm

Net weight:419kg

Electricity:1.1kw

Scan QR to Read

Links:https://globefindpro.com/products/21749.html

Links:https://globefindpro.com/products/21749.html

Recommended Products

-

Infrared Heating Oven

Infrared Heating Oven

-

Shoe Repair Finisher

Shoe Repair Finisher

-

Chiller Machine

Chiller Machine

-

Heat Insulation Block

Heat Insulation Block

-

Shoe Strip Cutting Machine

Shoe Strip Cutting Machine

-

Automatic Footwear Production Line

Automatic Footwear Production Line

-

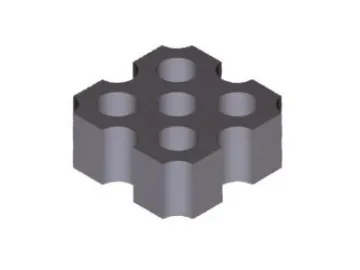

Interlocking Block

Interlocking Block

-

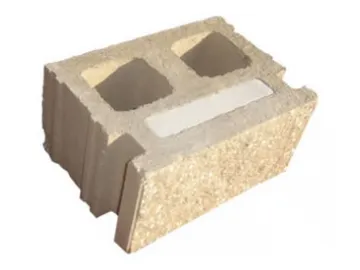

Concrete Hollow Block

Concrete Hollow Block

-

Sole Sander Machine

Sole Sander Machine

-

Concrete Grass Pavers

Concrete Grass Pavers

-

Dissolved Air Flotation (DAF) Thickener

Dissolved Air Flotation (DAF) Thickener

-

Band Scourer, Roughing and Cementing Machine

Band Scourer, Roughing and Cementing Machine

Hot Products