CNC Lathe

CNC metal lathes are primarily used for cutting surfaces and threading parts, as well as grooving, drilling, broaching, reaming, boring and more, A Y axis can be added to allow the lathe to carry out turn mill combined functions. A tool storage area can also be added to the lathe, allowing users to change tools during machining in order to achieve different machining requirements.

| Items | Specifications |

| Stroke | |

| Maximum turning diameter (mm) | Φ420 |

| Maximum stroke (X/Z) (mm) | 600/360 |

| Maximum machining automatic feeding diameter (mm) | Φ45 |

| Spindle | |

| Spindle motor power (KW) | 5.5 |

| Spindle speed (rpm) | 10-6000 |

| Axial drive | |

| Rapid traverse (X/Z) (m/min) | 30 |

| Others | |

| Max. allowable bar diameter (mm) | Φ125 |

| Minimum input unit (mm) | 0.001 |

| Repeated positioning accuracy (mm) | 0.003 |

| Roundness (mm) | 0.003 |

| Taper (mm) | 0.005mm/100 |

| surface roughness | Ra0.4 |

| Turning tool size (mm) | 20*20 |

| Machining length / deep hole machining (mm) | 280/130 |

| Total weight (kg) | 3000 |

| Center height (mm) | 63 |

| Machine dimensions (mm) | 2120*1730*1700 |

Scan QR to Read

Links:https://globefindpro.com/products/24379.html

Links:https://globefindpro.com/products/24379.html

Recommended Products

-

CNC Gantry Machining Center, Series LM-2013

CNC Gantry Machining Center, Series LM-2013

-

CNC Gantry Machining Center, Double Column Machining Center

CNC Gantry Machining Center, Double Column Machining Center

-

CNC Slant Bed Turning Center,CNC turn Mill Center

CNC Slant Bed Turning Center,CNC turn Mill Center

-

CNC Gantry Machining Center, Series LM-3022

CNC Gantry Machining Center, Series LM-3022

-

Fresh Air Purifying Filtration Machine

Fresh Air Purifying Filtration Machine

-

CNC Vertical Machining Center (2 Linear Guide Way)

CNC Vertical Machining Center (2 Linear Guide Way)

-

CNC Turning Center, Series CK6140

CNC Turning Center, Series CK6140

-

CNC Milling Machine, Series EMC-1280

CNC Milling Machine, Series EMC-1280

-

CNC Gantry Machining Center, Series LM-3017

CNC Gantry Machining Center, Series LM-3017

-

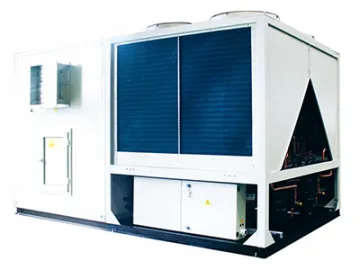

Fresh Air Ventilation Packaged Rooftop Unit

Fresh Air Ventilation Packaged Rooftop Unit

-

Residential Pool Heat Pump

Residential Pool Heat Pump

-

CNC Milling Machine

CNC Milling Machine