As a glass and mirror manufacturer with extensive experience, Jimmy Glass provides a variety of makeup mirrors, including magnifying glass mirrors, vanity mirrors, cosmetic mirrors, fog-free mirrors, and amplifying mirrors.

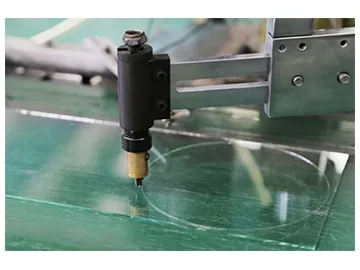

Our makeup mirrors use float glass as the substrate after a series of processes, including purification level washing, primary inspection, vacuum coating, secondary inspection, eco-friendly treatment, and cutting. We use computer-controlled glass cutting machines imported from Japan and Taiwan to ensure the glass cutting quality.

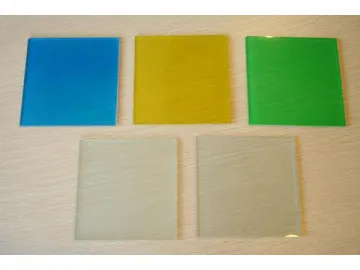

We use sputtering coating to coat the mirror surface in a vacuum environment for a variety of effects. Coating materials available to choose from include Al, Ge, Si, SiO2, Ni2O5, ITO, Ag, Cu, and stainless steel.

Features

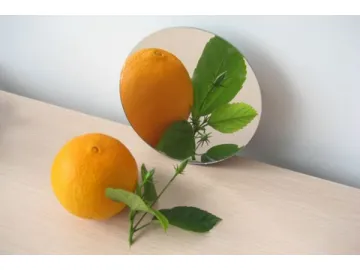

Our makeup mirrors feature a high reflectivity and offers an exceptional image quality, even in low light environments.

The glass substrate is strictly chosen according to the transmission, flatness, and thickness.

Normalized inspection processes ensures each makeup mirror has an excellent corrosion resistance, acid and alkali resistance, adhesion, and thermal shock resistance.

The mirror can be turned into a magnifying mirror glass after the bending process.

Custom Specifications

We can manufacture customized cosmetic mirrors with a variety of different characteristics to meet special requirements.

Thickness: 0.7mm-2.0mm (±0.1mm)

Shapes: Round, rectangle, polygon, etc.

Post processing: Printing, sandblasting, glass etching

Magnification Vanity Glass Mirror

Cosmetic Mirror

Curved Cosmetic Mirror

Fog-free makeup mirror

Glass Etching makeup mirror

Sandblasted Cosmetic Mirror

Printed Vanity Glass Mirror

Links:https://globefindpro.com/products/25075.html

-

Infrared Tunnel Oven (Forced Convection Oven)

Infrared Tunnel Oven (Forced Convection Oven)

-

-

LED UV Curing Conveyor System

LED UV Curing Conveyor System

-

Magnifying Glass Optical Mirror

Magnifying Glass Optical Mirror

-

Contact Heat IR Oven Line

Contact Heat IR Oven Line

-

150°C Vacuum Oven

150°C Vacuum Oven

-

Curved Glass Optical Mirror

Curved Glass Optical Mirror

-

600°C Vacuum Oven

600°C Vacuum Oven

-

UV Curing for lable printing

UV Curing for lable printing

-

Mini UV Laboratory Curing Machine

Mini UV Laboratory Curing Machine

-

Microwave Tunnel Oven

Microwave Tunnel Oven

-

Eco-friendly Optical Mirror

Eco-friendly Optical Mirror