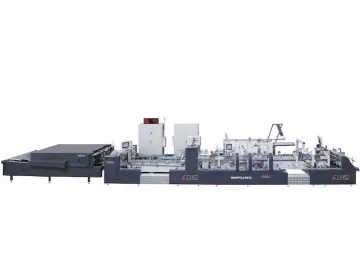

Sheet to Sheet Laminator (Board and Paper)

Description

This series of automatic sheet to sheet laminator uses coating rolls to uniformly coat the glue on the single-face corrugated sheet, which will be bound together with the synchronously conveyed sheet. Then through the pressurized conveyor unit, the sheet and corrugated sheet are laminated together to form corrugated board.

Among them, the laminating machine can mount 5000 sheets per hour. This laminator is applicable to all packaging industries for all kinds of laminating production, like display stands, sidewalk sign, outdoor displays, posters, carton packaging, etc.

Sheet to Sheet Laminator models| Model | Length | Width | Height | Weight | Electrical connected load | Conveyor unit length |

| ETH 1450 | 13.5m | 2.4m | 2.7m | 7.2 Ton | 12.7 kW | 5100mm |

| ETH 1450H | 14.5m | 2.4m | 2.7m | 7.8Ton | 15.7 kW | 6000mm |

| ETH 1650 | 14.5m | 2.6m | 2.7m | 8.5Ton | 15.7 kW | 6000mm |

Carton board

Corrugated board

Parameters

Processed materials

| Min. Carton board | 250 g/m² |

| Corrugated flute type | E, F, B, C, A and 5-layer flute |

| Sheet weight | 250 to 350 g/m² |

| Sheet size | From 380x380 to 1450x1100 mm |

| Production speed | 5000 sheets/h |

| Machine speed | 130 meters/min |

| Feeder height | 2600mm |

| Conveyor motor speed | 2.2 kW |

| Laminating unit main motor power | 5.5 kW |

| Laminating accuracy | 1.5mm |

Sheet feeder Flute feeder

Laminating unit Pressurized conveyor unit

Scan QR to Read

Links:https://globefindpro.com/products/25332.html

Links:https://globefindpro.com/products/25332.html

Recommended Products

-

Die Cutting Foil Stamping Press 1050-C type Hot Foil Stamping Cutting Line

Die Cutting Foil Stamping Press 1050-C type Hot Foil Stamping Cutting Line

-

Die Cutting Foil Stamping Press 1050-SC type Hot Foil Stamping Cutting Line

Die Cutting Foil Stamping Press 1050-SC type Hot Foil Stamping Cutting Line

-

Die Cutting Foil Stamping Press 1050-FC type Hot Foil Stamping Cutting Line

Die Cutting Foil Stamping Press 1050-FC type Hot Foil Stamping Cutting Line

-

Carton and Box Folding Gluing Line 800 type Carton Machine

Carton and Box Folding Gluing Line 800 type Carton Machine

-

Die Cutting Foil Stamping Press 1050-FSC type Hot Foil Stamping Machine

Die Cutting Foil Stamping Press 1050-FSC type Hot Foil Stamping Machine

-

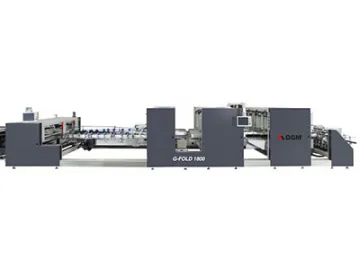

Folding Gluing Creasing Line 1650 type Folding Carton Gluing Machine

Folding Gluing Creasing Line 1650 type Folding Carton Gluing Machine

-

Carton Folding and Gluing Line X800 type High Speed Folding Machine

Carton Folding and Gluing Line X800 type High Speed Folding Machine

-

Carton Folding Gluing Line 2400 type Folding Carton Gluing Machine

Carton Folding Gluing Line 2400 type Folding Carton Gluing Machine

-

High Speed Carton Folding and Gluing Line 800 type Folder Gluer Machine

High Speed Carton Folding and Gluing Line 800 type Folder Gluer Machine

-

Carton Folding Gluing Line 1800 type Automatic Gluing Machine

Carton Folding Gluing Line 1800 type Automatic Gluing Machine

-

Die Cutting Machine 1050 type Flatbed Die Cutter, Automatic Die Cutting Equipment

Die Cutting Machine 1050 type Flatbed Die Cutter, Automatic Die Cutting Equipment

-

High Speed Folding and Gluing Line 3200 type Carton Folder Gluer

High Speed Folding and Gluing Line 3200 type Carton Folder Gluer