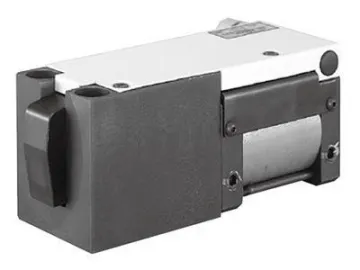

KOSMEK HC Die Clamps

The KOSMEK HC die clamp operation is reliable, ensuring a strong retention and clamping force, even without an air supply.

It features a wide application range, including longitudinal mold changing and horizontal mold changing. It is also suitable for horizontal injection press and vertical injection presses in a variety of specifications.

Technical parameter

Optional type

| Type | HC0102 | HC0162 | HC0252 | HC0402 | HC0632 | HC1002 | HC1602 | HC2502 | ||

| Die clamp capacity | (kN) | 9.8 | 15.7 | 24.5 | 39.2 | 61.7 | 98 | 157 | 245 | |

| Retention | Air pressure | 0. 39MPa | 9.8 | 15.7 | 24.5 | 39.2 | 61.7 | 98 | 157 | 245 |

| (kN) | Air pressure | OMPa | 2.9 | 5.9 | 7.8 | 11.8 | 17.6 | 26.5 | 40.9 | 65 |

| Clamping force (kN) | Air pressure | 0. 49MPa | 7.8 | 13.7 | 19.6 | 31.4 | 48 | 75.5 | 124 | 190 |

| Air pressure | 0.39MPa | 6.9 | 11.8 | 16.7 | 26.5 | 41.2 | 63.7 | 104 | 160 | |

| Air pressure | OMPa | 2 | 2.9 | 4.9 | 6.9 | 9.8 | 14.7 | 23.5 | 35 | |

| Max stroke | (mm) | 2 | 2 | 2.1 | 2.3 | 2.6 | 2.8 | 3 | 3.3 | |

| Clamping stroke | (mm) | 1 | 1 | 1 | 1.1 | 1.2 | 1.2 | 1.2 | 1.3 | |

| Reserved stroke | 1 | 1 | 1.1 | 1.2 | 1.4 | 1.6 | 1.8 | 2 | ||

| cylinder volume | Clamping side | 56 | 94 | 144 | 259 | 444 | 773 | 1334 | 2468 | |

| (cm3) | Releasing side | 52 | 88 | 135 | 244 | 416 | 729 | 1262 | 2346 | |

| Supply pressure | Recommended pressure | 0.49 | ||||||||

| (MPa) | Min pressure | 0.39 | ||||||||

| Operating temperature | Below 70°C(over 70°C, please contact us) | |||||||||

| Operating frequency | Below 20 times/ day (or you need contact us) | |||||||||

| Type | ∫ |

| HC0102 | 113 |

| HC0162 | 119 |

| HC0252 | 111 |

| HC0402 | 156 |

| HC0632 | 179 |

| HC1002 | 167 |

| HC1602 | 152 |

| HC2502 | 190 |

① Bolt

② Clamp confirm switch

③ Releasing confirm switch

④ Air supply of clamping

⑤ Air supply of releasing

⑥ Clamping joint

⑦ Max stroke

⑧ Clamping stroke

⑨ Hanger bolt hole

⑩ Reserved stroke

Features

The power source is normal compressed air, so users do not need to worry about oil leakage that will dirty up the clamping machine and surrounding environment. This also means there is no need to worry about operating oil stocks or fire hazards. All circuits use air pressure piping, thus making piping operations more convenient. There is no oil leakage during pipe disassembly, which makes equipment maintenance easier. Compared to the KOSMEK GWA die clamps, it has the same installation distance between holes, giving the two series an excellent compatibility. Compared to mold changes by oil pressure, this HB die clamp features a lower operating pressure, ensuring a higher durability under high temperatures. The price of the HB die clamps is lower than oil pressure die clamps during long term usage.

Dimensions

| Type | E | FA | FB | FC | G | J | K | L | M | P | MIN.Q | R | S | T | U | UA | UB | VA | VB | W | X | Z | (Standard)h |

| HC0102 | 66 | 50 | 6 | 6 | 16 | 10.5 | 75.5 | 159 | 39.5 | 5.6 | 46 | 15 | 33 | 8 | - | 525 | 505 | 68.5 | 7.5 | 12 | M8 | - | 20±0.3 |

| HC0162 | 76 | 60 | 6 | 6 | 19 | 12 | 86 | 174 | 48 | 6.1 | 55 | 15 | 39 | 95 | - | 60 | 58 | 73 | 7.5 | 15 | M10 | - | 20±0.3 |

| HC0252 | 85.5 | 72 | - | - | 25 | 13 | 100.5 | 195 | 48.5 | 7.4 | 84 | 2 | 50 | 11 | - | 70 | 70 | 70 | 11 | 22 | M12 | - | 30±0.3 |

| HC0402 | 1045 | 90 | - | - | 30 | 15.5 | 117.5 | 217 | 66.5 | 8.8 | 61 | 2 | 62 | 14 | - | 845 | 845 | 74.5 | 11.5 | 27 | M16 | - | 30±0.3 |

| HC0632 | 128 | 110 | - | - | 36 | 17.5 | 139.5 | 254 | 77 | 9.9 | 75 | 3 | 76 | 17 | - | 99 | 99 | 89 | 11.5 | 33 | M20 | - | 35±0.3 |

| HC1002 | 150 | 135 | 9.5 | - | 48 | 20 | 163.5 | 287 | 100.5 | 11 | 120 | 3 | 95 | 20 | - | 109.5 | 1095 | 1065 | 8.5 | 36 | M24 | - | 40±0.3 |

| HC1602 | 182 | 142 | 9.5 | 8.5 | 55 | 23 | 203 | 355 | 132 | 13 | 203 | 5 | 104 | 17 | 40 | 131.5 | 131*5 | 128 | 12 | 30 | M20 | 6 | 40±0.3 |

| HC2502 | 227 | 170 | 10 | 10 | 65 | 26 | 253 | 435 | 125.5 | 17 | 245 | 5 | 130 | 20 | 50 | 167 | 167 | 158 | 12 | 37 | M24 | 10 | 50±0.3 |

Scan QR to Read

Links:https://globefindpro.com/products/27223.html

Links:https://globefindpro.com/products/27223.html

Recommended Products