Holding Furnace

Holding furnace mainly used for heat preservation, standing and casting of molten aluminum. Holding furnace has similar structure as the melting furnace and they differ from each other depends on the power used in combustion system as holding furnace uses smaller power. Since the holding furnace has similar structure as the melting furnace and hence it can replace melting furnace to guarantee production for a short term. The external material of the holding furnace made of Q235 steel whereas its internal made of refractory bricks and high alumina brick. Non-adhesive aluminum castable or high strength low cement castable is used for internal casting. We can provide custom-made products such as holding furnace using natural gas, holding furnace using electric heater, holding furnace using heavy oil burner, holding furnace using diesel for our customers.

DetailsBricklaying of furnace lining

Bricklaying with strong refractory materials which is applicable in any furnace type and any alloy smelting.

Easy and convenient for maintenance, low maintenance cost. More suitable for economical furnace type. The economical furnace has smaller tonnage. For example, aluminum melting furnace with volume 10 tons and below is suitable with lining bricklaying.

Casting lining

The better the mixing of the refractory lining, the longer the lifespan of the bricklaying structure.

Using non-adhesive aluminum castable or strong strength cement castable. As such, the furnace has excellent sealing property and therefore the overall heat preservation of the furnace is guaranteed. Heat energy lost is minimized.

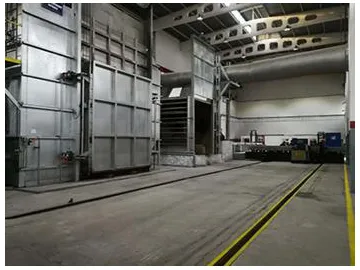

Example of industrial furnace

Links:https://globefindpro.com/products/27391.html

-

CNC Multi-Axis Milling Machining Service

CNC Multi-Axis Milling Machining Service

-

LED Light Strip 2216 SMD

LED Light Strip 2216 SMD

-

Flexible UV LED Tape Light

Flexible UV LED Tape Light

-

CNC Machining Industrial Automation Accessories

CNC Machining Industrial Automation Accessories

-

CNC Machining Motor Components

CNC Machining Motor Components

-

Addressable LED Strip Light Kit

Addressable LED Strip Light Kit

-

Homogenizing Furnace, using Natural Gas Heater

Homogenizing Furnace, using Natural Gas Heater

-

CNC Mill-turn Machining Service

CNC Mill-turn Machining Service

-

CNC Turning Lathe Machining Service

CNC Turning Lathe Machining Service

-

Melting and Holding Furnace, using Natural Gas Burner

Melting and Holding Furnace, using Natural Gas Burner

-

Aluminum Based Alloy Plant Cooling Equipment

Aluminum Based Alloy Plant Cooling Equipment

-

Holding Furnace, using Heavy Oil Burner

Holding Furnace, using Heavy Oil Burner