Hydraulic Ironworker (Steel Plate Punching, Shearing, Notching Machine)

Introduction  Process Capability

Process Capability

Technical competence

The hydraulic ironworker uses a hydraulic transmission, allowing it to shear punch and die shear a variety of plate steel, square steel, round steel, angle steel, channel steel, and I-beam steel. It is equipped with a shearing gauge.

| Material | QC35Y-16 | QC35Y-20 | QC35Y-30 | QC35Y-50 |

| Round steel mm | 45 | 50 | 65 | 80 |

| Square steel mm | 40×40 | 50×50 | 55×55 | 70×70 |

| Equilateral angle steel 90 shear mm | 120×120×12 | 140×140×12 | 180×180×16 | 200×200×20 |

| Equilateral angle steel 45 shear mm | 50×50×5 | 50×50×5 | 80×80×8 | 100×100×20 |

| T-steel 90ºshear mm | 125×125×12 | 140×140×12 | 180×180×16 | 200×200×20 |

| T-steel 45ºshear mm | 60×60×8 | 70×70×10 | 80×80×10 | 100×100×20 |

| I-steel shear mm | 120×74×5 | 160×86×6 | 280×124×10.5 | 400×200×16 |

| U-steel mm | 120×53×5.5 | 160×60×6.5 | 280×86×11.5 | 400×200×16 |

| Model | Q35Y-16 | Q35Y-20 | Q35Y-25 | Q35Y-30 | Q35Y-40 | Q35Y-50 |

| Punching pressure (ton) | 60 | 90 | 120 | 160 | 200 | 250 |

| Max.shearingthickness of steel plates (mm) | 16 | 20 | 25 | 30 | 40 | 50 |

| Strength of steel plates | ≤450 | ≤450 | ≤450 | ≤450 | ≤450 | ≤450 |

| Angle of shearing | 7° | 8° | 8° | 8° | 8° | 8° |

| Shearing sizes of one stroke (TxW) (mm) | 16x25 8x400 | 20x330 10x480 | 25x330 16x600 | 30x355 20 x 600 | 40x335 30x600 | 30x600 |

| Slider stroke (mm) | 80 | 80 | 80 | 80 | 100 | 80 |

| Number of stroke (min-l) | 11-20 | 12-20 | 8-18 | 6-16 | 6-16 | 8-12 |

| Depth of throat (mm) | 300 | 355 | 400 | 600 | 600 | 600 |

| Punching thickness | 18 | 22 | 28 | 30 | 38 | 50 |

| Max. diameter of punching (mm) | 25 | 30 | 35 | 38 | 40 | 35 |

| Main motor (kW) | 5.5 | 5.5 | 7.5 | 11 | 18.5 | 32 |

| Overall dimensions (LxWxH) (mm) | 1730x820 x 1900 | 1900x900 x 1950 | 2355x960 x 2200 | 2800x1100 x 2500 | 2800x1100 x 2500 | 3000x1150 x 2600 |

| Net weight (kg) | 1800 | 2400 | 4000 | 6500 | 8000 | 12500 |

Scan QR to Read

Links:https://globefindpro.com/products/28322.html

Links:https://globefindpro.com/products/28322.html

Recommended Products

-

Hydraulic Notching Machine

Hydraulic Notching Machine

-

Pneumatic Punch Press Machine

Pneumatic Punch Press Machine

-

Open Type Power Press Machine

Open Type Power Press Machine

-

Upper Roller Universal Plate Bending Machine

Upper Roller Universal Plate Bending Machine

-

Hydraulic Punching Machine

Hydraulic Punching Machine

-

Multifunction Hydraulic Punching Notching Machine

Multifunction Hydraulic Punching Notching Machine

-

WF67Y Metal Bending Hydraulic Press Brake

WF67Y Metal Bending Hydraulic Press Brake

-

WH67K(Y) series Metal Hydraulic Press Brake

WH67K(Y) series Metal Hydraulic Press Brake

-

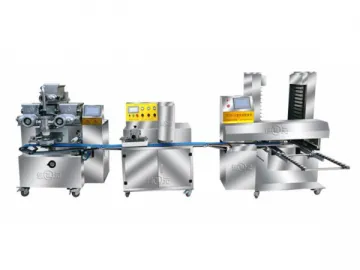

Mooncake Production Line

Mooncake Production Line

-

Steamed Bun Machine (Stuffed Buns Line)

Steamed Bun Machine (Stuffed Buns Line)

-

Automatic Dough Encrusting Machine

Automatic Dough Encrusting Machine

-

Automatic Dough Sheeting and Cutting Machine

Automatic Dough Sheeting and Cutting Machine

Hot Products