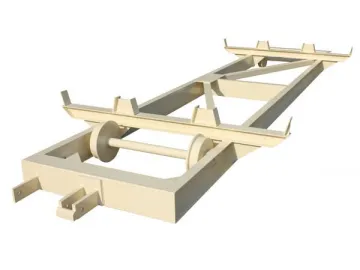

Single-Shaft Slitter Rewinder, ZTM-B

Video Suitable for conversion of paper, kraft paper and adhesive labels  Specifications

Specifications

Details Unwind station with hydraulic loader for mother rolls

Pneumatic brake shaftless unwind unit (optional)

Perforation punching shaft (optional)

Rewinder with air shaft

Rewind station with hydraulic lifter for unloading finished rolls Rewinder (max. diameter 1000-1500mm) Features This single-shaft slitter rewinder is ideal for manufacturing adhesive label, kraft paper or other paper products requiring large winding diameters and narrow slitting widths. The entire slitter rewinder machine is controlled by PLC system, permitting operator to easily control the machine through touch screen. Magnetic particle clutch or pneumatic brake is used on unwind station, and constant unwinding tension is maintained through PLC automatic compensation of roll diameter change. Rewinding control is managed by a vector variable frequency drive, therefore maintaining a constant speed. Rewind station has a hydraulic lifting mechanism to unload finished rolls. Hydraulic loader is fitted at unwind stand for automatic loading of paper rolls, more suitable for workshops where lifting equipment such as overhead cranes are not available. It can significantly reduce labor intensity and shorten the time for loading operations. The unwind stand is provided with options of shafted or shaftless loading method to suit actual needs. EPC (edge position control) web guide system ensures the accurate position of the material. Photoelectric sensor or hydraulic web guiding unit is optional. This slitting machine also has functions of start buffer, anti loosening, constant speed setting, roll diameter measuring, etc. Tags: label slitting machine

perforating rewinding machine

single-shaft log slitter

single shaft winder slicer

log roll cutting machine

Our ZTM-B single-shaft slitter rewinder is suited to cut down the parent roll of paper materials such as paper, kraft paper and adhesive labels into desired widths, and then rewind the final product back into narrower rolls with one rewind shaft. This paper roll slitting machine reaches a production speed of up to 250m/min.

| Model | ZTM-B 1300 | ZTM-B 1600 |

| Max. web width | 1300mm | 1600mm |

| Max. unwind diameter | Ø1200mm | Ø1500mm |

| Max. rewind diameter | Ø1200mm | Ø1500mm |

| Min. slitting width | 50mm | 50mm |

| Mechanical speed | 250 m/min | 250m/min |

| Substrate thickness | 40-500gsm | 40-500gsm |

| Machine weight | 4000kg | 5200kg |

| Overall dimensions | 3900×3500×1500mm | 4200×3900×1500mm |

| Voltage | 380V three phase | 380V three phase |

Pneumatic brake shaftless unwind unit (optional)

Perforation punching shaft (optional)

Rewinder with air shaft

Rewind station with hydraulic lifter for unloading finished rolls Rewinder (max. diameter 1000-1500mm) Features This single-shaft slitter rewinder is ideal for manufacturing adhesive label, kraft paper or other paper products requiring large winding diameters and narrow slitting widths. The entire slitter rewinder machine is controlled by PLC system, permitting operator to easily control the machine through touch screen. Magnetic particle clutch or pneumatic brake is used on unwind station, and constant unwinding tension is maintained through PLC automatic compensation of roll diameter change. Rewinding control is managed by a vector variable frequency drive, therefore maintaining a constant speed. Rewind station has a hydraulic lifting mechanism to unload finished rolls. Hydraulic loader is fitted at unwind stand for automatic loading of paper rolls, more suitable for workshops where lifting equipment such as overhead cranes are not available. It can significantly reduce labor intensity and shorten the time for loading operations. The unwind stand is provided with options of shafted or shaftless loading method to suit actual needs. EPC (edge position control) web guide system ensures the accurate position of the material. Photoelectric sensor or hydraulic web guiding unit is optional. This slitting machine also has functions of start buffer, anti loosening, constant speed setting, roll diameter measuring, etc. Tags: label slitting machine

perforating rewinding machine

single-shaft log slitter

single shaft winder slicer

log roll cutting machine

Scan QR to Read

Links:https://globefindpro.com/products/2847.html

Links:https://globefindpro.com/products/2847.html

Recommended Products

-

Slurry Agitator

Slurry Agitator

-

Slurry Storage Tank

Slurry Storage Tank

-

Finished Product Conveyor Line

Finished Product Conveyor Line

-

Hardening Car

Hardening Car

-

Tongue and Groove Milling Device

Tongue and Groove Milling Device

-

Tiling Hoister

Tiling Hoister

-

Economical Slitter Rewinder, ZTM-D

Economical Slitter Rewinder, ZTM-D

-

Natural Gas Generator Sets with Baudouin Engines

Natural Gas Generator Sets with Baudouin Engines

-

Diesel Generator Sets with SDEC Engines, TSO Series

Diesel Generator Sets with SDEC Engines, TSO Series

-

Packaging Machine

Packaging Machine

-

Diesel Generator Sets with MTU Engines, TX Series

Diesel Generator Sets with MTU Engines, TX Series

-

Diesel Generator Sets with Baudouin Engines, TB Series

Diesel Generator Sets with Baudouin Engines, TB Series

Hot Products