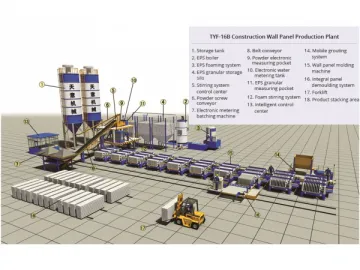

TYF-16B Construction Wall Panel Production Plant (Stationary Type, Calcium Silicate Board Compound Wall, GRC Glass Reinforced Concrete Panel)

TYF-16B stationary construction wall panel production plant is applicable for the production of two-side calcium silicate board lightweight compound wall panel or GRC lightweight wall panel and the suitable materials include cement, fly ash, EPS polystyrene particles, sand and ceramsite. 10 pieces of panels can be molded one time.

It adopts stationary type design so that the operation is much easier and it can also reduce investment cost and lower the failure rate. However, it has certain requirements for the site.

Researched and developed independently by TANY, the whole production line is equipped with automatic configuration of large-scale stirring system, mobile grouting system and integral panel demoulding and flipping palletizing system. Aggregate conveying and measuring functions are added to this production line, contributing to precise material ratio and high molding efficiency. Besides, the operations are much easier and labor intensity and cost can be largely decreased.

Patent number: ZL201320164478.9

| One-time molding quantity | Thickness | Width | Length |

| 10 | 75mm | 610mm | 2440mm/3000mm |

| 10 | 90mm | ||

| 8 | 120mm | ||

| 6 | 150mm |

| One-time molding quantity | Core tube diameter | Core tubequantity | Thickness | Width | Length |

| 10 | Φ38mm | 90 | 75mm | 600/610mm | Adjustable within 3000mm |

| 10 | Φ52mm | 70 | 90mm | ||

| 8 | Φ74mm | 40 | 120mm | ||

| 6 | Φ52mm | 84 | 150mm |

Note: The above dimensions are normal ones. TANY can provide customized production lines according to your requirements for special wall panel sizes.

Main equipment

(1) Wall panel molding machine

(2) Foam stirring system

(3) Mobile grouting system

(4) Mobile automatic stacking machine (Panel demoulding)

| Power of heating system | 20 kW |

| Power of vibration system | 0.75 kW |

| Power of hydraulic system | 3 kW |

| Hydraulic working pressure | 8 Mpa |

| Maximum hydraulic working pressure | 16 Mpa |

| Capacity of hydraulic tank | 60 L |

| Structural composition | Host machine, hydraulic system, power distribution system, heating system, vibration system, core tubes |

| Model | TY-13 |

| Power of screw conveyer | 11kW×2 |

| Feeding capacity of mixer | 2000 L |

| Discharging capacity of mixer | 2000 L |

| Mixing speed | 32.5 r/min |

| Largest mixing aggregate particles | 8 mm |

| Power of mixing motor | 18.5 kW |

| Maximum powder measurement | 800 kg |

| Maximum water measurement | 500 kg |

| Power of water feeding motor | 2.2kW |

| Powder feeding pneumatic butterfly valve | DN300 |

| Water feeding pneumatic butterfly valve | DN100 |

| Mixing cycle | 10-15 minutes |

| Number of mixing blade | 8 |

| Discharging method | Pneumatic butterfly valve |

| Metering hopper vibrator | Pneumatic vibrator |

| Power of foaming machine | 2.2 kW |

| Power of foaming compressor | 4 kW |

| Power of air compressor | 5.5 kW |

| Note: technical parameters for enlarged mixing plant | |

| Pumping pressure in Theory | High pressure | 0.5 Mpa |

| Low pressure | 0.4Mpa | |

| Transport capacity in theory | High pressure | 5 Mpa |

| Low pressure | 9.4 Mpa | |

| Max. transport distance | Horizontal | 300 mm |

| Vertical | 120 mm | |

| Main motor power | 7.5 kW | |

| Hopper volume | 1.5m³ | |

| Loading height | 1000 mm | |

| Hydraulic oil tank volume | 60L | |

| Distribution valve form | Ball valve | |

| Main machine weight | 500kg | |

| Frame size: L×W×H | 1785×960×1700mm | |

Close

| Model | TY-13 |

| Overall dimension | 4500L×4600W×1050H mm |

| Total power | 7 kW |

| Demoulding motor power | 1.5 kW |

| Travel motor power | 1.5 kW |

| Hydraulic system motor power | 4 kW |

| Hydraulic working pressure | 10 Mpa |

| Maximum hydraulic working pressure | 16 Mpa |

| Stacking platform | 4500L×2300W mm |

Index

construction partition wall, precast wall panel, wall production line, interior wall machines

Links:https://globefindpro.com/products/30468.html

-

Automatic Flip Machine

Automatic Flip Machine

-

Double Roller Paint Coating Machine

Double Roller Paint Coating Machine

-

Paint Leveling Drying Tunnel

Paint Leveling Drying Tunnel

-

TYJ16 Construction Extruded Wall Panel Production Plant

TYJ16 Construction Extruded Wall Panel Production Plant

-

TYF13 Prestressed Wall Panel Machine

TYF13 Prestressed Wall Panel Machine

-

TY03A/TY03B Precast Wall Panel Machine

TY03A/TY03B Precast Wall Panel Machine

-

Roller Conveyor

Roller Conveyor

-

Air Knife Dewatering Unit

Air Knife Dewatering Unit

-

Vibrating Pellet Screener

Vibrating Pellet Screener

-

Type II Primer Sander Machine (Double Sanding, Single Polishing)

Type II Primer Sander Machine (Double Sanding, Single Polishing)

-

Electric Heating Spiral Conveying Dryer

Electric Heating Spiral Conveying Dryer

-

Thermal Insulation Coating Line

Thermal Insulation Coating Line