Electric Heating Spiral Conveying Dryer

Applications

The electric heating spiral conveying dryer uses a high heat-conducting oil to heat the materials, and the rated drying capacity is 500-4000kg/h. The maximum surface temperature of the vibration disk can reach more than 200 degrees. It is suitable for materials with ultra-high temperature heating and drying requirements. It has obvious value added effects in the use of modified engineering plastic production line.

Material types

Vibrating spiral conveyors are standard equipment for many industries to elevate bulk materials. They can convey, dry and cool the plastics granules, rubber granules, chemical and pharmaceutical intermediates, metal salts, welding powder, glass batch, catalysts, abrasives and ash as well as milk powder, powdered coffee, tea, nuts, nutrients and cereals.

| Grade | SCD05-30 | SCD1-40 | SCD2-50 | SCD3-60 | SCD4-70 | ||||

| Nominal Capacity (kg/h) | 500 | 1000 | 2000 | 3000 | 4000 | ||||

| Diameter (mm) | Ø600 | Ø700 | Ø800 | Ø900 | Ø1000 | ||||

| Inlet Height (mm) | 600 | 680 | 700 | 800 | 900 | ||||

| Outlet Height (mm) | 3000 | 4000 | 5000 | 6000 | 7000 | ||||

| Motor Power (Kw) | 0.75*2 | 1.1*2 | 1.7*2 | 2.3*2 | 2.9*2 | ||||

| Heating Pressure (bar) | 5 | 5 | 5 | 5 | 5 | ||||

| Heat Transfer Medium | heat transfer oil | ||||||||

| Drying Time (min) | 3-4 | 4-6 | 5-7 | 6-8 | 7-9 | ||||

Operational Principle

The electric heating spiral conveying dryer has an electric heat-conducting oil jacket, which is directly energized to heat the oil inside the jacket. The heat-conducting oil heats the vibrating disk evenly to dry the material particles.

Features

The electric heating jacket is formed by pressing the die, and the electric heating jacket is not deformed by the pressure of 6 kg.

High heating efficiency

It adopts the multi-channel immersion heater which not has direct contact with the heat conduction oil, so the safety performance is high. It can spread the heat evenly and do not produce local heat.

It can set the temperature of the jacket and the material for double circuit heating to enhance the drying effect according to the customer's special production needs.

The material lifting drying multifunction system is easy to maintain because there is no external pipeline.

Adjustment of the power of electric heating is available.

The dryer has no pipeline to dissipate heat, so heat loss is minimal.

According to the needs of customers, the water cooling device can be selected in the discharge section to further enhance the drying effect.

The spiral elevator can be equipped with the external insulation layer according to the customer's requirements, such as a stainless steel cover or silicone coat to meet different material production.

Index

bulk material handling equipment, lifting conveyor, vertical conveyor, granule conveying

Links:https://globefindpro.com/products/30461.html

-

Type II Primer Sander Machine (Double Sanding, Single Polishing)

Type II Primer Sander Machine (Double Sanding, Single Polishing)

-

Vibrating Pellet Screener

Vibrating Pellet Screener

-

Air Knife Dewatering Unit

Air Knife Dewatering Unit

-

Roller Conveyor

Roller Conveyor

-

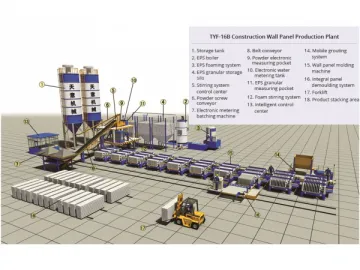

TYF-16B Construction Wall Panel Production Plant (Stationary Type, Calcium Silicate Board Compound Wall, GRC Glass Reinforced Concrete Panel)

TYF-16B Construction Wall Panel Production Plant (Stationary Type, Calcium Silicate Board Compound Wall, GRC Glass Reinforced Concrete Panel)

-

Automatic Flip Machine

Automatic Flip Machine

-

Thermal Insulation Coating Line

Thermal Insulation Coating Line

-

Primer Sander Machine (Single Sanding, Single Polishing)

Primer Sander Machine (Single Sanding, Single Polishing)

-

Industrial Vacuum Drying Machine

Industrial Vacuum Drying Machine

-

Multifunction Vibrating Sieves and Screen Equipment

Multifunction Vibrating Sieves and Screen Equipment

-

Thickness Sander Machine

Thickness Sander Machine

-

UV curing and solid color fluorocarbon roller paint coating line

UV curing and solid color fluorocarbon roller paint coating line