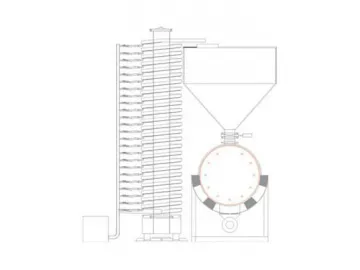

Industrial Vacuum Drying Machine

Applications

The design of a closed inlet and outlet structure and fully enclosed heat insulation cover are added to improve the conveying of materials while simultaneously undergoing high efficiency vacuum drying. This makes the system suitable for drying and improvement of various types of plastic particles and powder.

| Grade | SCV05-30 | SCV1-40 | SCV2-50 | SCV3-60 | SCV4-70 |

| Nominal Capacity (kg/h) | 500 | 1000 | 2000 | 3000 | 4000 |

| Diameter (mm) | φ600 | φ700 | φ800 | φ900 | φ1000 |

| Inlet Height (mm) | 600 | 680 | 700 | 800 | 900 |

| Outlet Height (mm) | 3000 | 4000 | 5000 | 6000 | 7000 |

| Motor Power (Kw) | 0.75*2 | 1.1*2 | 1.7*2 | 2.3*2 | 2.9*2 |

| Heating Pressure (bar) | 5 | 5 | 5 | 5 | 5 |

| Heat Transfer Medium | Hot water, steam, heat conductive oil | ||||

| Drying Time (min) | 3-4 | 4-6 | 5-7 | 6-8 | 7-9 |

Operational Principle

The bottom of the vibrating disc uses an independent jacket, which is heated by the central heating system. The heating mediums include hot water, steam and heat conduction oil.

The materials enter from the vacuum feeding system into the vibration conveyance dryer, and are continuously transported by the conveyer. Under the double action of heat conduction and thermal radiation of the jacket, the material is heated, then evaporated water vapor is pumped out. The fully dried materials are then discharged from the vacuum discharging system.

Features

It can continuously dry or lift the plastic granules and powder.

It can be used to dry materials in a low temperature environment, especially for materials that are easy to oxidize and become discolored, due to the use of a vacuum low vapor pressure.

The user can adjust the stay time and dry temperature.

Large heat exchange area ratio & high heating efficiency.

The overall drying energy consumption is low, because the heat loss mainly comes from the loss of water evaporation. There is no hot wind and other media to bring out the heat.

The closed operation ensures no dust or other impurities can contaminate materials, thus meeting requirements for a clean production.

Space saver

Benefits

The energy consumption is significantly reduced and the comprehensive benefits are significantly improved.

High drying efficiency & stable product quality.

Drying and lifting automation relies on a single device to save labor.

No mechanical rotating mechanism means there is a low maintenance workload.

Index

drying equipment, dryer, vertical conveying

Links:https://globefindpro.com/products/30458.html

-

Primer Sander Machine (Single Sanding, Single Polishing)

Primer Sander Machine (Single Sanding, Single Polishing)

-

Thermal Insulation Coating Line

Thermal Insulation Coating Line

-

Electric Heating Spiral Conveying Dryer

Electric Heating Spiral Conveying Dryer

-

Type II Primer Sander Machine (Double Sanding, Single Polishing)

Type II Primer Sander Machine (Double Sanding, Single Polishing)

-

Vibrating Pellet Screener

Vibrating Pellet Screener

-

Air Knife Dewatering Unit

Air Knife Dewatering Unit

-

Multifunction Vibrating Sieves and Screen Equipment

Multifunction Vibrating Sieves and Screen Equipment

-

Thickness Sander Machine

Thickness Sander Machine

-

UV curing and solid color fluorocarbon roller paint coating line

UV curing and solid color fluorocarbon roller paint coating line

-

Spiral Vibratory Elevator Integrated Drying System

Spiral Vibratory Elevator Integrated Drying System

-

Dust Cleaner Machine

Dust Cleaner Machine

-

Steam Jacket Spiral Conveying Dryer

Steam Jacket Spiral Conveying Dryer