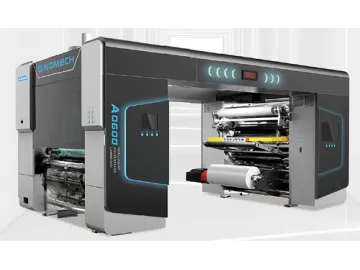

Digital Solventless Laminator A600D

All units including laminating, adhesive mixing, heating, exhaust, cooling, corona treating are integrated in the lamination machine, which are central controlled by the touch screen. In addition, they are allowed to communicate with the management system and printing system.

Transmission mechanism for the transfer rollerThe solventless lamination machine is specially designed with a superior quality transmission mechanism for the sleeved transfer roller, ensuring constant-pressure contact between the transfer roller and two steel rollers.

Recipe systemAll lamination machines are equipped with a recipe system for job file storage to be easily recalled from the memory. During the repetitive production, the production parameters can be quickly recalled from the memory. Parameter reset of each process can be made with a single click in a quick and accurate manner.

Open to be integrated into Sinomech Cloud Platform for Solventless Laminators (SCPSL), and easy access to online support system, providing great convenience in operation, maintenance, and technical support.

Online data management platform for lamination processAccumulates lamination process parameters set based on various substrates, lamination structures, and adhesives to create a data system covering common lamination processes used in the flexible packaging.

Optional Continuous adhesive mixing and dispensing systemContinuous adhesive dispensing increases production flexibility with consistent and accurate dispensing to multiple applications simultaneously.

Sleeve type transfer rollerThe sleeved transfer roller enables very quick and easy on-board sleeve exchange.

Automatic control and measurement systemIn-line grammage measurement and automatic control for adhesive applied greatly enhances productivity and finished product quality.

Get in TouchLinks:https://globefindpro.com/products/3443.html

-

Mild Steel Enclosure for Honeywell

Mild Steel Enclosure for Honeywell

-

Solventless Laminator A400

Solventless Laminator A400

-

Tube Filling and Sealing Machine

Tube Filling and Sealing Machine

-

CINOVA Gearless CI Flexo Printing Press

CINOVA Gearless CI Flexo Printing Press

-

Versaline 16 Lane Ice Cream Equipment Stainless Steel Ice Pop Mold-1

Versaline 16 Lane Ice Cream Equipment Stainless Steel Ice Pop Mold-1

-

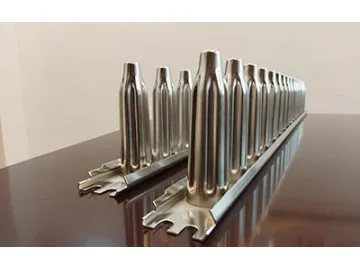

Versaline 16 Lane Ice Cream Equipment Stainless Steel Ice Pop Mold-3

Versaline 16 Lane Ice Cream Equipment Stainless Steel Ice Pop Mold-3

-

Solventless Laminator A350

Solventless Laminator A350

-

Dust Collecting Crushing Set, WF-C Series

Dust Collecting Crushing Set, WF-C Series

-

Oscillating Granulator, YK Series

Oscillating Granulator, YK Series

-

Tablet Coating Machine / Tablet Coater, BG-E Series

Tablet Coating Machine / Tablet Coater, BG-E Series

-

Digicam Combi Laminator

Digicam Combi Laminator

-

Hot Air Circulation Pharmaceutical Oven

Hot Air Circulation Pharmaceutical Oven