Roller Compactor (for Dry Granulation), LGP200-75

The LGP200-75 roller compactor is a dry granulation system to improve the flow characteristics and density of the material. It adopts mechanical or pneumatic conveyor to deliver the material to the compaction zone via feed screw, and two counter rotating rolls compact the material into high-density sheets. The compacted sheets are divided into smaller pieces and then milled to form granules with desired size. The roller compactor is widely used in dry granulation applications for pharmaceutical, food, supplement, candy and household chemical industries.

Integrated structure, compact size, portable design, easy to operate;

Exchangeable bowls can accommodate different batch sizes;

Flexibly suitable for R&D, clinical batches and production;

Top spray for granulation, Wurster bottom spray for coating;

Excellent process control system, with functions of management of formulation and process parameters, data logging, audit trail, electronic signature, etc.;

Can be integrated with isolator, providing OEB4/5 level containment solution; Technical Specifications

| Roller diameter (mm) | Ø200 |

| Roller width (mm) | 75 |

| Min. batch (g) | 30 (optional function) |

| Max. production capacity (kg/h) | 400 (lactose) |

| Max. roller pressure (kN/cm) | 22 |

| Hydraulic pressure (bar) | 50-240 |

| Max. gap width of rollers (mm) | 5 |

| Particle size, mesh | 10-80 (adjustable) |

| Material temperature (℃) | ≤35 |

| Mixing motor (kW) | 0.25 |

| Feeding motor (kW) | 1.5 |

| Roller compaction motor (kW) | 5.5 |

| Crushing motor (kW) | 0.37 |

| Pre-granulation motor (kW) | 1.5 |

| Fine-granulation motor (kW) | 1.5 |

| Hydraulic unit motor (kW) | 1.5 |

| Vacuum pump (kW) | 0.22 |

| Mixing speed (rpm) | 5-25 |

| Feeding speed (rpm) | 10-60 |

| Roller compaction speed (rpm) | 5-40 |

| Crushing speed (rpm) | 260 |

| Pre-granulation speed (rpm) | 50-200 |

| Fine-granulation speed (rpm) | 50-200 |

| Total power (kW) | 12.34 |

| Power supply | 380V/50HZ/3P |

| Air pressure (bar) | 4-8 |

| Air consumption (L/h) | 50 |

| Overall dimensions (mm) | 2000×1700×2000 |

| Weight (kg) | 2400 |

wet granulator

pharma processing equipment

fluid bed processor

Scan QR to Read

Links:https://globefindpro.com/products/3664.html

Links:https://globefindpro.com/products/3664.html

Recommended Products

-

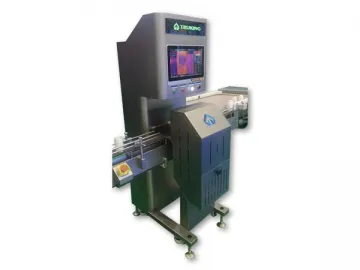

Seal Inspection Machine, CSV-200

Seal Inspection Machine, CSV-200

-

Multifunction Fluid Bed Dryer, TVP Series

Multifunction Fluid Bed Dryer, TVP Series

-

Laboratory Fluid Bed Dryer, TVP Series

Laboratory Fluid Bed Dryer, TVP Series

-

Laboratory Bin Blender, DHS Series

Laboratory Bin Blender, DHS Series

-

Cone Mill, ZLZ Series

Cone Mill, ZLZ Series

-

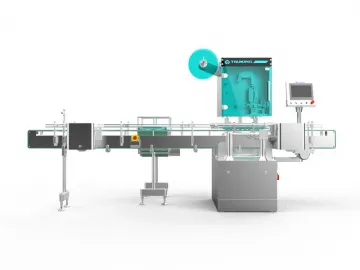

Wrap-around Labeling Machine, LM-W01

Wrap-around Labeling Machine, LM-W01

-

GH019-HA Semi-automatic 6 inch Sewing Thread Winding Machine

GH019-HA Semi-automatic 6 inch Sewing Thread Winding Machine

-

IBC Post Hoist / Column Lift for Bins, TX Series

IBC Post Hoist / Column Lift for Bins, TX Series

-

Fluid Bed Dryer, TV Series

Fluid Bed Dryer, TV Series

-

Capsule Polisher and Sorter, JFP-110A

Capsule Polisher and Sorter, JFP-110A

-

Fixed Bin Blender, DH Series

Fixed Bin Blender, DH Series

-

Desiccant Inserter (200 bottles/min), ISD-200

Desiccant Inserter (200 bottles/min), ISD-200