GH018-A Automatic High Speed Sewing Thread Winding Machine

GH018-A Automatic High Speed Sewing Thread Winding Machine  Technical Parameters

Technical Parameters

Features Automatic bobbin feeding and automatic winding system offer high automation. Automatic bobbin feeding and no bobbin auto-stop Non-contact broken yarn detector is sensitive. Automatic bobbin changing is fast and stable, greatly reducing labor cost. Computer-based yarn length automatic measuring system comes with an accuracy of ±0.5%. Automatic control of winding linear speed is flexibly set within 100-1000 m/min. Grooved drum yarn guide system offers fast speed and low noise. Grooved drum is manufactured with special material and is polished, being smooth and wear-resistant and having no damage to the yarn. Pump-based cycling-type oiling device allows for the setting of oil wheel speed ratio, ensuring uniform oiling combined with the constant linear speed. Each oil wheel is configured with a filter to prevent oil spray and oil waste. High productivity: each machine offers an output of 5 kg yarns per hour, and the daily output is up to 110kg based on 22 working hours. The efficiency is 5-6 times higher than that of traditional winding machines. Details Leave a Message

GH018-A fully automatic high speed sewing thread winding machine is applicable to the winding of embroidery threads, sewing threads and so on into 2-4 inches cones.

This sewing thread winder features automatic bobbin feeding and winding system, a computer-controlled automatic yarn length counter, frequency control, a slotted spool yarn guide device, and a pump-based cycling-type oiling device. Thus, the machine offers good shape formation, high efficiency, easy operation, assured safety and reliability, and wide applicability.

| Model | GH018-A auto |

| Take-up tube | Conic shape |

| Spindle number | 4 |

| Drive | Individual motor per spindle |

| Control | Computer controlled |

| Traverse length | 2”-4” |

| Spindle speed | 10000rpm |

| Mechanical speed | 200~1000 m/min |

| Weight | 500kg |

| Installed power | 1.2kW |

| Air pressure | 2 KGS |

| Take-up package diameter | Φ140mm |

| Power supply | 220V (single phase) or 380 V (three phases), 1.2kW |

| Frequency | 50/60Hz |

| Compressed air | 0.3MPa |

| Dimension | 1800×760×1840mm |

Scan QR to Read

Links:https://globefindpro.com/products/3678.html

Links:https://globefindpro.com/products/3678.html

Recommended Products

-

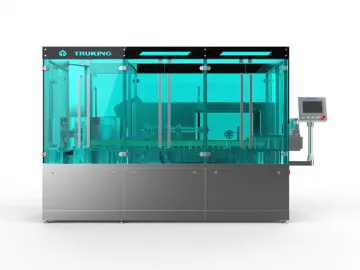

Stick Pack Machine for Liquid Dosage (12 lanes), SP-L12

Stick Pack Machine for Liquid Dosage (12 lanes), SP-L12

-

Bottle Unscrambler (250 bottles/min), UB-250

Bottle Unscrambler (250 bottles/min), UB-250

-

Belt Cleaners / Scrapers

Belt Cleaners / Scrapers

-

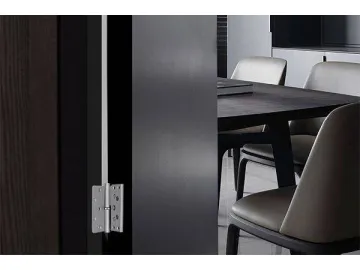

3D Adjustable Hinges

3D Adjustable Hinges

-

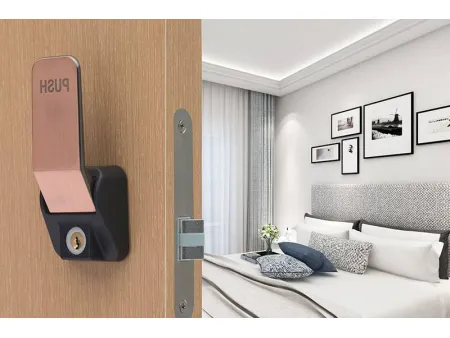

Push Pull Mortise Lock with Mortise Cylinder

Push Pull Mortise Lock with Mortise Cylinder

-

Impact Beds

Impact Beds

-

GH019-SY Semi-automatic King Spool Thread Winding Machine

GH019-SY Semi-automatic King Spool Thread Winding Machine

-

Automatic Bin Blender, DHZ Series

Automatic Bin Blender, DHZ Series

-

Stick Packing and Arranging Machine, SP-S12 Series

Stick Packing and Arranging Machine, SP-S12 Series

-

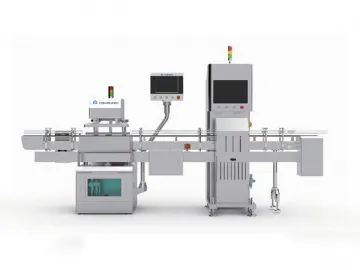

Induction Cap Sealing Machine, CSI-200

Induction Cap Sealing Machine, CSI-200

-

IBC Bin for Mixing, HLDF Series

IBC Bin for Mixing, HLDF Series

-

Medical High Purity Nitrogen Generator

Medical High Purity Nitrogen Generator

Hot Products