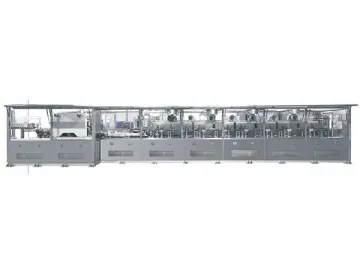

Linear Plastic Bottle Blowing Machine

The linear plastic bottle blowing machine is used for automatically blowing plastic bottles like IV solution bottles in two steps. It is rigidly built and equipped with electrical and mechanical protection. The stainless steel frame and plexiglass protective cover both contribute to the elegant appearance and long service life of the bottle blowing equipment.

Main Characteristics

The linear plastic bottle blowing machine comes with a new high speed vertical rotary preform feeding system. The changing of bottle performs of different specifications can be easily realized through simple adjustment, without changing any parts.

The new generation intelligent thyristor power regulator, closed loop control for heater power, voltage anti-interference function and stable power output combine to ensure even thickness of the bottle and high efficiency of the machine.

The advanced three point toggle type mold lock unit makes mold opening and closing quick, stable, without noise. The adoption of piston type high pressure mold locking, with strong locking strength, greatly improves the blowing quality.

The bottle blowing machine adopts new type servo motor drive and uses high strength guide mechanism to accurately control mold opening, closing speed and position, which helps to save time, reduce impact and improve equipment stability.

The use of innovative steel ball type torque limiter makes it possible to effectively protect the relative mechanisms of the blowing machine. In addition, the torque limiter has automatic reset function, making maintenance easier.

The plastic bottle blowing equipment adopts full servo motor control for procedures like preform taking, preform conveying, stretching, mold closing and bottle sending out. The electric cylinder and servo motor are world famous brand products.

According to customers' requirements, the machine can equipped with remote monitor to do fault diagnosis and procedure changes through the internet.

Main Technical Parameters

| Machine models | |||||||

| Item | CPP4 | CPP6 | CPP8 | CPP10 | CPP12 | ||

| Designed capacity | 100-250 ml | 4000 pcs/h | 6000 pcs/h | 8000 pcs/h | 10000 pcs/h | 12000 pcs/h | |

| 500 ml | 3600 pcs/h | 5400 pcs/h | 7200 pcs/h | 9000 pcs/h | 10800 pcs/h | ||

| Preform material | BOPP | ||||||

| Mould cavity no. | 4 | 6 | 8 | 10 | 12 | ||

| Mould cavity distance | 95.25 mm | ||||||

| Max. mould thickness | 260 mm | ||||||

| Max. height of bottle | 220 mm | ||||||

| Bottle dimension | Round bottle | φ50-76 mm | |||||

| Square bottle | 60-84 mm(diagonal) | ||||||

| Bottle mouth outer dia. | 18-22 mm | ||||||

| Air source | Low pressure compressed air | 8-10 Bar 4000 L/H | 8-10 Bar 6000 L/H | 8-10 Bar 8000 L/H | 8-10 Bar 10000 L/H | 8-10 Bar 12000 L/H | |

| High pressure compressed air | 20-25 Bar 4000 L/H | 20-25 Bar 6000 L/H | 20-25 Bar 8000 L/H | 20-25 Bar 10000 L/H | 20-25 Bar 12000 L/H | ||

| Cool water | Heating part | 20-30 ℃, 4-10 m³/h | |||||

| Mould part | 5-15 ℃, 3-8 m³/h | ||||||

| Power supply | 380 V, 50 Hz, three phase four wire | ||||||

| Heating power | 160 kW | 160 kW | 160 kW | 192 kW | 192 kW | ||

| Installed power | 180 kW | 180 kW | 180 kW | 225 kW | 225 kW | ||

| Machine weight | 8.8 T | 12.8 T | 13.8 T | 14.6 T | 15.6 T | ||

| Outer dimension (m) | Main set (LXWXH) | 8X1.65X2.7 | 8.8X1.65X2.7 | 10.8X1.65X2.7 | 11.8X1.65X2.7 | 12.8X1.65X2.7 | |

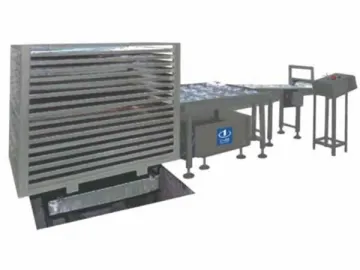

| Preform loading part (LXWXH) | 4x3x3.7 | ||||||

As a professional linear plastic bottle blowing machine manufacturer and supplier in China, we also offer soft infusion bag drying machine, glass bottle stoppering machine, sterilizing dryer, and much more

Scan QR to Read

Links:https://globefindpro.com/products/36786.html

Links:https://globefindpro.com/products/36786.html

Recommended Products

-

Introduction

Introduction

-

Bag Loading Machine, Bag Unloading Machine

Bag Loading Machine, Bag Unloading Machine

-

Vials Filling and Sealing Machine

Vials Filling and Sealing Machine

-

Vial Labelling Machine

Vial Labelling Machine

-

Ampoule Washing, Drying, Filling and Sealing Machine

Ampoule Washing, Drying, Filling and Sealing Machine

-

Fine Bottle Washing Machine

Fine Bottle Washing Machine

-

Glass Ampoule Ultrasonic Cleaning Machine

Glass Ampoule Ultrasonic Cleaning Machine

-

Plastic Bottle Labelling Machine

Plastic Bottle Labelling Machine

-

Glass Ampoule Sterilizing Drying Machine

Glass Ampoule Sterilizing Drying Machine

-

Vial Capping Machine

Vial Capping Machine

-

Vertical Ultrasonic Vial Cleaner

Vertical Ultrasonic Vial Cleaner

-

Product Features

Product Features

Hot Products