Tablet Coating Machine, GBS Series

GBS series high efficiency automatic coating machine is suitable for coating tablets, pills or candies with organic film, water-soluble film, slow and controlled release film, sugar and chocolate coating, having extensive applications in pharmaceutical, food and confectionery industries. This automatic tablet coating machine is manufactured in conformity with GMP requirements, featuring high efficiency, energy saving, and safe operation.

| Model | GBS5 | GBS10 | GBS20 | GBS50 | GBS100 | GBS200 | GBP400 | GBP600 | GBP800 |

| Production capacity (L/batch) | 0.3-5 | 1-10 | 2-20 | 5-50 | 10-100 | 20-200 | 160-400 | 240-600 | 320-800 |

| Drum speed (r/min) | 5-44 | 3-31 | 3-28 | 3-22 | 2-19 | 2-16 | 2-13 | 2-12 | 2-12 |

| Drum motor power (kW) | 0.37 | 0.75 | 1.1 | 1.5 | 2.2 | 3 | 5.5 | 7.5 | 7.5 |

| Inlet air motor power (kW) | 0.37 | 0.75 | 1.1 | 1.5 | 2.2 | 3 | 5.5 | 7.5 | 7.5 |

| Inlet air volume (m3/h) | 300 | 500 | 1000 | 2000 | 3000 | 4500 | 6000 | 8000 | 8000 |

| Outlet air motor power (kW) | 1.1 | 1.1 | 2.2 | 4 | 5.5 | 7.5 | 15 | 22 | 22 |

| Outlet air volume (m3/h) | 1000 | 1000 | 2000 | 3000 | 4000 | 6000 | 8000 | 12000 | 12000 |

Scan QR to Read

Links:https://globefindpro.com/products/3693.html

Links:https://globefindpro.com/products/3693.html

Recommended Products

-

Vertical Capsule Sorting Polisher, JFP Series

Vertical Capsule Sorting Polisher, JFP Series

-

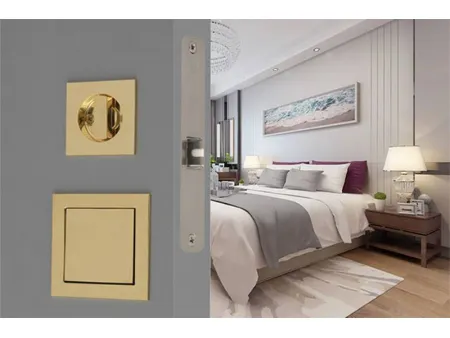

Flush Pull Mortise Lock with Thumbturn

Flush Pull Mortise Lock with Thumbturn

-

Lab Tablet Coater, GBM Series

Lab Tablet Coater, GBM Series

-

Conveyor Idlers / Rollers

Conveyor Idlers / Rollers

-

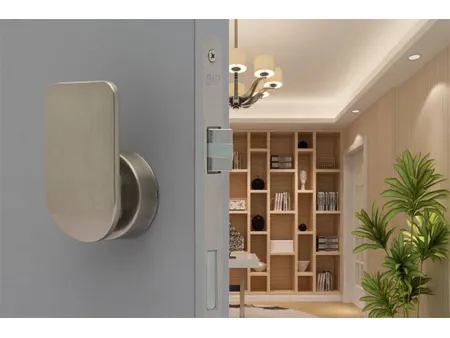

Push Pull Latch

Push Pull Latch

-

Universal Troughed Belt Conveyor

Universal Troughed Belt Conveyor

-

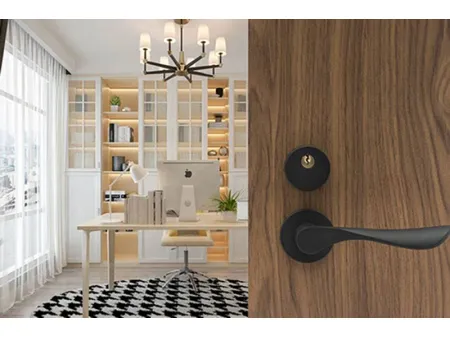

Mortise Lever Lock with Mortise Cylinder

Mortise Lever Lock with Mortise Cylinder

-

Laboratory High-Shear Mixer Granulator, TM10

Laboratory High-Shear Mixer Granulator, TM10

-

Automatic Capsule Filling Machine, NJP Series

Automatic Capsule Filling Machine, NJP Series

-

Conveyor Covers

Conveyor Covers

-

Automatic Vacuum Conveyor, QVC Series

Automatic Vacuum Conveyor, QVC Series

-

Conveyor Pulleys

Conveyor Pulleys

Hot Products