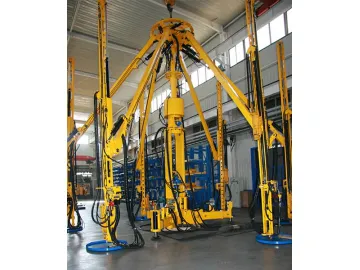

Hydraulic Production Drilling Jumbo for Mining CYTC70 (HT72)

Production Jumbo Drill, Underground Equipment, Hydraulic Production Drill, Mining Jumbo

Different from the CYTC76 (HT71) hydraulic production drilling jumbo for mining, this production jumbo drill features a drilling depth of 25m and a drilling diameter of 51-76mm. It is useful for small-size mines with its tunnel boring size range of 3. 5m*3.5m to 4.5m*4.5m. The hydraulic production drill meets special mining positioning requirements due to its high degree of mechanization and efficient operation. The equipment is fitted with a HC109RP rock drill to achieve incredible continuous drilling for extended lengths of time without overheating or damage to components. This type of underground equipment is an ideal choice for mining operations that utilize sub-level caving methods.

Major Strengths of the Hydraulic Production Drill

1. A high-torque motor and a high-efficiency rock drill work in tandem to create deep, straight holes.

2. The locating system of this drill is electronically controlled while the rock drill and anti-jamming system are both PLC controlled for an incredible amount of precision.

3. Equipped with a dual-buffering system, the rock drill is suitable for drilling many kinds of rocks.

Detailed Data of the Mining Jumbo

| Air system | |

| Rated pressure | MPa |

| Rated flow | 10 L/min |

| Boom | |

| Boom compensation | 750mm |

| Parallel moving capacity | Good |

| Flip angle of propeller | ±180° |

| Slewing angle of propeller | ±180° |

| Pitching angle of propeller | 5/-95 |

| Pitching angle of boom | 50°/-30° |

| Max. oscillating angle of boom | ±30° |

| Propeller | |

| Total length | 2850mm |

| Length of drilling pipe | 1000mm |

| Drilling depth | < 30m |

| Propelling force | < 15KN |

| Base plate | |

| Engine | Yammar 4TNV98T |

| Type | In-line water cooled diesel engine |

| Cylinder dia. * stroke | 98*110 mm |

| Swept volume | 3.319 L |

| Rated output power | 53.1 KW |

| Max. torque | 280N.m |

| Fuel consumption | 257g/KW·h |

| Fixed seat | Yes |

| FOPS-approved protective roof | Yes |

| Horn | Yes |

| Articulated steering | ±35 |

| Hydraulic power steering system | Yes |

| 2-pump, 4-motor, 4-wheel hydraulic transmission | Yes |

| Service brakes | Hydraulic |

| Emergency and parking brakes | Leaf spring, hydraulic separating |

| Fixed front wheel | Yes |

| Swing angle of rear wheel | ±7 ° |

| Tire | 8.25-15 |

| Approach & departure angle | 14 ° |

| Hydraulic jacks of front fork | 2 pieces of extendable type |

| Hydraulic jacks of rear fork | 2 pieces |

| Volume of fuel tank | 40 L |

| Silencer | Yes |

| Electrical system | 12 Volt |

| Batteries | 2×12V, 195Ah |

| Tramming lights | 8×25W, 12V |

| Working lights | 2×500W 220V |

| Fire extinguisher | Yes |

| Central lubrication system | Yes |

| Alarm | Yes |

| Reverse alarm | Yes |

| Lubrication warning kit | Yes |

| Control system | |

| Control system | Direct Control System, DCS |

| Auto anti-jamming | Yes |

| Dimensions | |

| Length | 8915mm |

| Width | 1650mm |

| Walking height | 2080mm |

| Max. height | 2780mm |

| Gross weight | 11500Kg |

| Wheelbase | 2700mm |

| Ground clearance | 295mm |

| Gradeability | 14° |

| Walking speed | 0~7.2Km/h |

| Electrical system | |

| Installed power | 62 KW |

| Power of main motor | 55 KW |

| Voltage | 380V or customized |

| Frequency | 50 Hz |

| Overload protection for motors | Yes |

| Digital voltmeter/ammeter in electrical cabinet | Yes |

| Phase sequence indicator | Yes |

| Battery charger | Yes |

| Timer | Yes |

| Cable reel | 70 m |

| Fault indicator | Yes |

| Hydraulic system | |

| Hydraulic pumps | 2 units, one for locating and the other for rotation |

| Pump unloaded while starting | Yes |

| Volume of hydraulic oil tank | 124 L |

| Oil temperature gauge | Yes |

| Water cooled oil cooler | Yes |

| Filtration | 20 µ m |

| Hydraulic oil | Mineral |

| Water system | |

| Working pressure | 2 MPa |

| Working flow | 67 L/min |

| Rock drill | |

| Rock drill | HC109 |

Links:https://globefindpro.com/products/37411.html

-

Wheel Loader ZL-16F

Wheel Loader ZL-16F

-

Hydraulic Bolting Jumbo for Mining CYTM41/2

Hydraulic Bolting Jumbo for Mining CYTM41/2

-

Hydraulic Drilling Jumbo for Tunneling CYTJ45A (HT82)

Hydraulic Drilling Jumbo for Tunneling CYTJ45A (HT82)

-

Vertical Shaft Drill SJZ (XFJD) Series

Vertical Shaft Drill SJZ (XFJD) Series

-

Pallet Fork

Pallet Fork

-

Rough Terrain Forklift

Rough Terrain Forklift

-

Steel Track Crawler Dumper HY-300

Steel Track Crawler Dumper HY-300

-

Hydraulic Scaling Jumbo XMPYT71/325 (HT62)

Hydraulic Scaling Jumbo XMPYT71/325 (HT62)

-

GM/Daewoo 12-Pin Adapter

GM/Daewoo 12-Pin Adapter

-

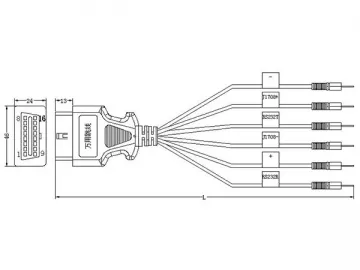

6-Pin Universal Jumper Cable

6-Pin Universal Jumper Cable

-

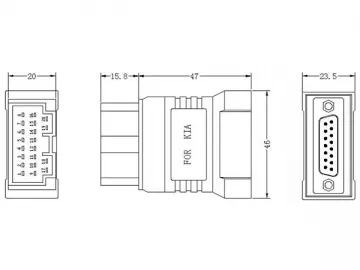

KIA 20-Pin Adapter

KIA 20-Pin Adapter

-

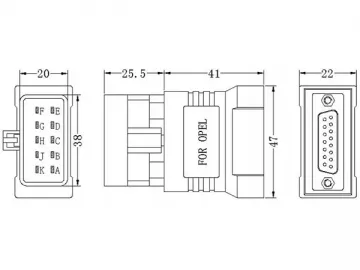

Opel 10-Pin Adapter

Opel 10-Pin Adapter