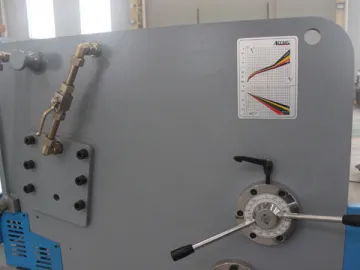

Hydraulic Swing Beam Shear

ACCURL manufactures a hydraulic swing beam shear for cutting of sheet metal with thicknesses between 4mm and 6000mm. The sheet metal shear can handle the large dimensions required in tube and roll forming manufacturing lines. The hydraulic swing beam shear can also be configured for piercing and blanking. We guarantee that ACCURL can provide you with the hydraulic shear that you are looking for.

Main Features

1. The hydraulic swing beam shear is completely streamlined and meets EU production requirements. The body construction is completed by automated robotic welders and it undergoes a stress relief process with an annealing treatment.

2. The QC12Y series hydraulic shearing machines are produced with a variety of cutting lengths and capacity options.

3. Equipped with a lighting-alignment function, the sheet metal cutting equipment can be quickly and easily adjusted to the right cutting angle. The stroke of the knife beam is adjusted in step-less mode.

4. The integrated hydraulic system leads to more reliable operation and easy maintenance. The hydraulic system is designed by Bosch-Rexroth in Germany.

5. The cutting blade is hydraulically driven with a nitrogen gas accumulator.

6. The entire hydraulic swing beam shear conforms to CE standards including the tiltable front finger guard and optical rear safety guard.

7. High quality shear blades that are easily maintained and replaced.

Standard Designs for the Hydraulic Swing Beam Shear

Rapid and precise blade clearance adjustment with a single handle on the side frame

Multi-edge blades for cutting aluminum, carbon steel, and stainless steel

Cutting line illumination and wire for shadow line cutting

Stroke counter

Quick cutting length adjustment

Hydraulic and electrical overload protection

Squaring arm and front support arms

Bed infill plates with ball transfers

Delta inverter with ball screw and polished rod with 0.01 mm accuracy.

Better Cuttings

Backgauge adjustment according to blade gap

Backgauge retraction feature

Sub-program and programming loop

Sequence repeat function

Auto cutting (Flying cut)

Optional Designs for the Hydraulic Swing Beam Shear

Roller rear supporting rack

Pneumatic sheet supporting system

Table mounted sheet angle cutting gauge

CNC control of plate thickness, backgauge position, and cutting length inputs

GoTo backgauge control

Specifications of the Hydraulic Swing Beam Shear

| Model(AC/MS7) | QC12Y-4×2500 | QC12Y-4×3200 | QC12Y-4×4000 | QC12Y-6×2500 | QC12Y-6×3200 | QC12Y-6×4000 | QC12Y-6×6000 | |

| Cut Thickness | mm | 4 | 4 | 4 | 6 | 6 | 6 | 6 |

| Cut Thickness | mm | 2500 | 3200 | 4000 | 2500 | 3200 | 4000 | 6000 |

| Shear Angle | Degree | 1°30' | 1°30' | 1°30' | 1°30' | 1°30' | 1°30' | 1°30' |

| SPM | min-1 | ≥ 22 | ≥ 18 | ≥ 12 | ≥ 16 | ≥ 12 | ≥ 10 | ≥ 7 |

| Back Gauge | mm | 20-600 | 20-600 | 20-600 | 20-600 | 20-600 | 20-800 | 20-800 |

| Throat Depth | mm | 85 | 85 | 85 | 145 | 145 | 145 | 140 |

| Main Motor | kW | 5.5 | 5.5 | 5.5 | 7.5 | 7.5 | 7.5 | 11 |

| Net Weight | kg | 3460 | 4280 | 6600 | 5140 | 6220 | 8520 | 17000 |

| Outline Size (L×W×H) | mm | 3100×1430×1450 | 3800×1555×1500 | 4600×1705×1600 | 3150×1500×1600 | 3850×1600×1620 | 4650×1850×1700 | 6780×2450×2100 |

| Model(AC/MS7) | QC12Y-8×2500 | QC12Y-8×3200 | QC12Y-8×4000 | QC12Y-8×5000 | QC12Y-8×6000 | QC12Y-12×2500 | QC12Y-12×3200 | |

| Cut Thickness | mm | 8 | 8 | 8 | 8 | 8 | 12 | 12 |

| Cut Thickness | mm | 2500 | 4000 | 3200 | 5000 | 6000 | 2500 | 3200 |

| Shear Angle | Degree | 1°30' | 1°30' | 1°30' | 1°30' | 1°16' | 2° | 2° |

| SPM | min-1 | ≥ 12 | ≥ 10 | ≥ 10 | ≥ 8 | ≥ 6 | ≥ 10 | ≥ 9 |

| Back Gauge | mm | 20-600 | 20-600 | 20-600 | 20-800 | 20-800 | 20-800 | 20-800 |

| Throat Depth | mm | 145 | 145 | 145 | 300 | 300 | 300 | 300 |

| Main Motor | kW | 11 | 11 | 11 | 18.5 | 18.5 | 18.5 | 18.5 |

| Net Weight | kg | 5900 | 10200 | 7360 | 18000 | 21800 | 9000 | 10700 |

| Outline Size (L×W×H) | mm | 3180×1680×1700 | 3880×1830×1720 | 4680×1980×1780 | 5855×2260×2100 | 6880×2260×2100 | 3300×2030×1840 | 4000×2100×1940 |

| Model(AC/MS7) | QC12Y-12×4000 | QC12Y-12×6000 | QC12Y-16×2500 | QC12Y-16×3200 | QC12Y-16×4000 | QC12Y-16×6000 | |

| Plate | 12 | 8 | 16 | 16 | 16 | 16 | |

| Cut Thickness | mm | 4000 | 6000 | 2500 | 3200 | 4000 | 6000 |

| Cut Thickness | mm | 1°54' | 2° | 2°9' | 2° | 2° | 2° |

| SPM | min-1 | ≥ 8 | ≥ 4 | ≥ 9 | ≥ 8 | ≥ 7 | ≥ 4 |

| Back Gauge | mm | 20-800 | 20-1000 | 20-800 | 20-800 | 20-1000 | 20-1000 |

| Throat Depth | mm | 300 | 320 | 315 | 320 | 320 | 320 |

| Main Motor | kW | 18.5 | 30 | 22 | 22 | 30 | 45 |

| Net Weight | kg | 13800 | 38000 | 11100 | 14300 | 19700 | 44000 |

| Outline Size (L×W×H) | mm | 4800×2270×2000 | 6900×2800×2500 | 3310×2240×2000 | 4030×2390×2100 | 4820×2490×2460 | 7100×2900×2650 |

| Model(AC/MS7) | QC12Y-20×3200 | QC12Y-20×6000 | QC12Y-25×2500 | QC12Y-25×3200 | QC12Y-32×2500 | QC12Y-32×3200 | |

| Cut Thickness | mm | 20 | 20 | 25 | 25 | 32 | 32 |

| Cut Thickness | mm | 3200 | 6000 | 2500 | 3200 | 2500 | 3200 |

| Shear Angle | Degree | 2°30' | 2°30' | 3° | 3° | 3°30' | 3°30' |

| SPM | min-1 | ≥ 5 | ≥ 4 | ≥ 5 | ≥ 5 | ≥ 4 | ≥ 4 |

| Back Gauge | mm | 20-1000 | 20-1100 | 20-1000 | 20-1000 | 20-1000 | 20-1500 |

| Throat Depth | mm | 320 | 150 | 325 | 325 | 350 | 350 |

| Main Motor | kW | 37 | 55 | 37 | 37 | 45 | 45 |

| Net Weight | kg | 22000 | 51000 | 20000 | 27000 | 32500 | 42100 |

| Outline Size (L×W×H) | mm | 4190×2695×2300 | 7100×3500×3050 | 3450×2650×2800 | 4130×3100×2800 | 3550×3100×2800 | 4335×3300×3280 |

Links:https://globefindpro.com/products/41962.html

-

Hydraulic CNC Shearing Machine

Hydraulic CNC Shearing Machine

-

Power Seal Hose Clamp

Power Seal Hose Clamp

-

High Speed C-Type Hydraulic Press

High Speed C-Type Hydraulic Press

-

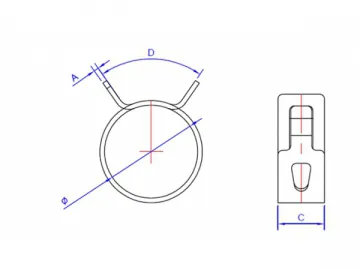

Rubber Lined P-Clip

Rubber Lined P-Clip

-

ACCURL-Bend - 6 Axes CNC Press Brake

ACCURL-Bend - 6 Axes CNC Press Brake

-

Four Column Deep Drawing Press HBP-40T~1600T

Four Column Deep Drawing Press HBP-40T~1600T

-

CNC Laser Cutting Machine

CNC Laser Cutting Machine

-

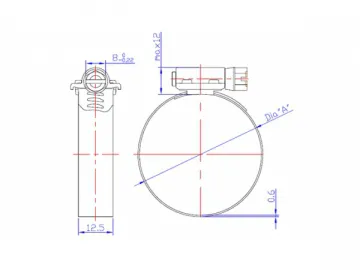

Spring-Loaded T-Bolt Clamp

Spring-Loaded T-Bolt Clamp

-

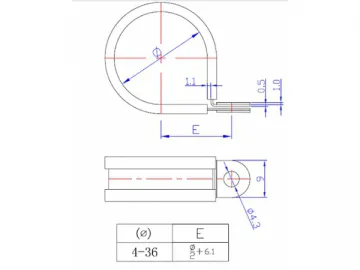

Spring Steel Hose Clamp

Spring Steel Hose Clamp

-

Turn-Key Hose Clamp (with Perforated Band)

Turn-Key Hose Clamp (with Perforated Band)

-

H-Frame Hydraulic Press (for SMC Molding)

H-Frame Hydraulic Press (for SMC Molding)

-

Heavy Duty Bolt Clamp (with Hollow Trunnions)

Heavy Duty Bolt Clamp (with Hollow Trunnions)