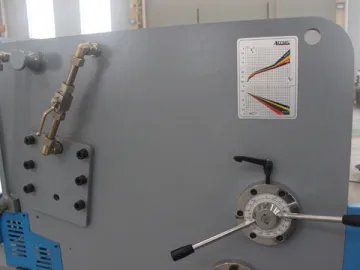

Hydraulic CNC Shearing Machine

The QC12K series of hydraulic CNC shearing machines are high performance metalworking machinery. The shearing equipment can adjust blade gap by CNC with an easy to use system that lets you make precise adjustments in order to get the perfect cut every time.

Features of the Hydraulic CNC Shearing Machine

Estun E200S user-friendly controller

Durable steel blades

Front support arm and side gauge

Hydraulic gap adjustment

Laser guided cutting

Angle gauge

Easy installation and training

Front curtain for finger protection

Durable choice for precise cutting operations

Sheet Metal Cutting Solutions based on Your Needs

ACCURL CNC Shears are designed to meet all of your fabricating needs when fast and flexible cuts are necessary. Metal fabrication equipment such as this can increase your production output as well as improve the quality of your metal fabrications.

Delem DAC310 CNC System - Optional Controller

User- friendly

Monochrome 130 x75mm LCD Box Panel

Cutting gap control

Programmed material types

Backgauge control and retract function

Easy configuration and operation

Rapid data input using an ergonomic keyboard with large keys.

Improved features

Blade gap and cutting length are automatically adjusted based on material type and thickness

Language selection

Protected microprocessor

Data recorded with internal SRAM memory

Upgradable using flash memory (RS 232).

Numerically programmable axis data.

16 input and output ports (24-32 options).

mm/inch conversion

EASYCUT page

Superior cutting settings

Backgauge adjustment according to blade gap.

Backgauge retraction feature.

Sub-program and programming loop.

Sequence repeat function.

Auto cutting (Flying cut).

Specifications

| Model(DC/MS7) | QC12K-4 × 2500 | QC12K-4 × 3200 | QC12K-4 × 4000 | QC12K-6 × 2500 | QC12K-6 × 3200 | QC12K-6 × 4000 | QC12K-6 × 6000 | |

| Cutting Thickness | mm | 4 | 4 | 4 | 6 | 6 | 6 | 6 |

| Cutting Length | mm | 2500 | 3200 | 4000 | 2500 | 3200 | 4000 | 6000 |

| Cutting Angle | ° | 1 ° 30' | 1 ° 30' | 1 ° 30' | 1 ° 30' | 1 ° 30' | 1 ° 30' | 1 ° 30' |

| SPM | min-1 | ≥ 22 | ≥ 18 | ≥ 12 | ≥ 16 | ≥ 12 | ≥ 10 | ≥ 7 |

| Back Gauge | mm | 20-600 | 20-600 | 20-600 | 20-600 | 20-600 | 20-800 | 20-800 |

| Throat Depth | mm | 85 | 85 | 85 | 145 | 145 | 145 | 140 |

| Main Motor | kW | 5.5 | 5.5 | 5.5 | 7.5 | 7.5 | 7.5 | 11 |

| Net Weight | kg | 3460 | 4280 | 6600 | 5140 | 6220 | 8520 | 17000 |

| Outline Size (L × W × H) | mm | 3100 × 1430 × 1450 | 3800 × 1555 × 1500 | 4600 × 1705 × 1600 | 3150 × 1500 × 1600 | 3850 × 1600 × 1620 | 4650 × 1850 × 1700 | 6780 × 2450 × 2100 |

| Model(DC/MS7) | QC12K-8 × 2500 | QC12K-8 × 3200 | QC12K-8 × 4000 | QC12K-8 × 5000 | QC12K-8 × 6000 | QC12K-12 × 2500 | QC12K-12 × 3200 | |

| Cutting Thickness | mm | 8 | 8 | 8 | 8 | 8 | 12 | 12 |

| Cutting Length | mm | 2500 | 4000 | 3200 | 5000 | 6000 | 2500 | 3200 |

| Cutting Angle | ° | 1 ° 30' | 1 ° 30' | 1 ° 30' | 1 ° 30' | 1 ° 16' | 2 ° | 2 ° |

| SPM | min-1 | ≥ 12 | ≥ 10 | ≥ 10 | ≥ 8 | ≥ 6 | ≥ 10 | ≥ 9 |

| Back Gauge | mm | 20-600 | 20-600 | 20-600 | 20-800 | 20-800 | 20-800 | 20-800 |

| Throat Depth | mm | 145 | 145 | 145 | 300 | 300 | 300 | 300 |

| Main Motor | kW | 11 | 11 | 11 | 18.5 | 18.5 | 18.5 | 18.5 |

| Net Weight | kg | 5900 | 10200 | 7360 | 18000 | 21800 | 9000 | 10700 |

| Outline Size (L × W × H) | mm | 3180 × 1680 × 1700 | 3880 × 1830 × 1720 | 4680 × 1980 × 1780 | 5855 × 2260 × 2100 | 6880 × 2260 × 2100 | 3300 × 2030 × 1840 | 4000 × 2100 × 1940 |

Links:https://globefindpro.com/products/41963.html

-

Power Seal Hose Clamp

Power Seal Hose Clamp

-

High Speed C-Type Hydraulic Press

High Speed C-Type Hydraulic Press

-

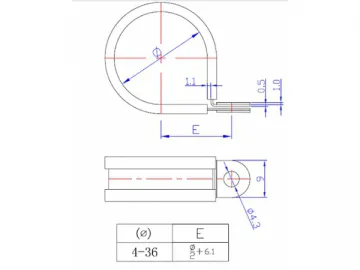

Rubber Lined P-Clip

Rubber Lined P-Clip

-

ACCURL-Bend - 6 Axes CNC Press Brake

ACCURL-Bend - 6 Axes CNC Press Brake

-

Four Column Deep Drawing Press HBP-40T~1600T

Four Column Deep Drawing Press HBP-40T~1600T

-

Hydraulic Guillotine Shear

Hydraulic Guillotine Shear

-

Hydraulic Swing Beam Shear

Hydraulic Swing Beam Shear

-

CNC Laser Cutting Machine

CNC Laser Cutting Machine

-

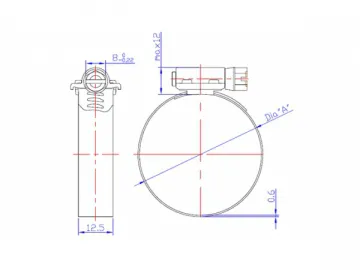

Spring-Loaded T-Bolt Clamp

Spring-Loaded T-Bolt Clamp

-

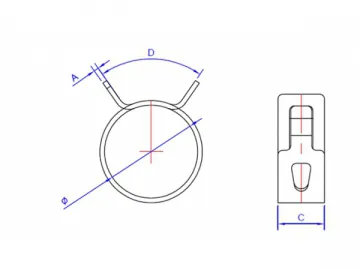

Spring Steel Hose Clamp

Spring Steel Hose Clamp

-

Turn-Key Hose Clamp (with Perforated Band)

Turn-Key Hose Clamp (with Perforated Band)

-

H-Frame Hydraulic Press (for SMC Molding)

H-Frame Hydraulic Press (for SMC Molding)