Silicon Steel

Silicon steel, also known as electrical steel, silicon electrical steel, lamination steel, relay steel, or transformer steel is specialty steel with silicon added to it, which improves its electrical resistivity and magnetic properties, and reduces hysteresis loss. This steel is ideal for various electrical applications where electromagnetic fields are of great importance, such as in transformers, magnetic coils and electrical motors.

Features of Silicon Steel

Great Electromagnetic Performance

The silicon steel comes with low iron loss and high magnetic induction, especially HiB steel which has lower iron loss and higher magnetic induction.

Good Shape

The material is often made in strips. Small longitudinal and transverse thickness difference ensures high lamination factor.

Insulating Coating

Uniform color, excellent insulativity, high adhesion strength, high heat resistance, great processability and superior corrosion resistance. Our silicon steel sheet is available in multiple insulating coating options, which have been REACH and RoHS certified that harmful matter content complies with domestic and overseas regulations on environmental protection.

Excellent Processability

Easy to die cut, with high dimensional accuracy.

Surface Quality

Our silicon steel features smooth surface, without defects such as rust, rolling marks, holes, cold-lap, folds, bubbles, etc.

Applications of Silicon Steel

| Applications | Oriented silicon steel | Non-oriented silicon steel | ||||

| HiB steel | General oriented silicon steel | Thin oriented silicon steel | High grade non-oriented silicon steel | Middle grade non-oriented silicon steel | Low grade non-oriented silicon steel | |

| Thickness (mm) | ||||||

| 0.23,0.27,0.30 | 0.27,0.30,0.35 | 0.15, 0.20 | 0.35,0.50,0.65 | 0.35, 0.50 | 0.50, 0.65 | |

| Large Motors | ★ | ★ | ★ | ★ | ||

| Medium-sized motor | ★ | ★ | ||||

| Small motor | ★ | |||||

| Micro motor | ★ | |||||

| Sealing motor | ★ | ★ | ||||

| Intermittent motor | ★ | |||||

| IF motor | ★ | |||||

| Compressor | ||||||

| Rectifier | ★ | ★ | ★ | |||

| Choke | ★ | ★ | ||||

| Relay | ★ | ★ | ||||

| Electromagnetic switch | ★ | ★ | ||||

| Large power transformer | ★ | ★ | ||||

| Small & medium power transformer | ★ | ★ | ★ | |||

| Distribution transformer | ★ | ★ | ||||

| Regulator | ★ | ★ | ★ | |||

| Reactor and magnetic amplifier | ★ | ★ | ★ | ★ | ||

| IF transformer | ★ | ★ | ★ | |||

| Transformer | ★ | ★ | ||||

| TV transformer | ★ | ★ | ★ | ★ | ||

| Radio transformer | ★ | ★ | ★ | ★ | ★ | |

| Welding transformer | ★ | ★ | ★ | ★ | ||

Magnetic Property and Lamination Coefficient

We guarantee every type of Jianhe silicon steel delivered with the performance of lower iron loss, higher magnetic induction and minimum lamination coefficient. Iron loss is regulated to be 1.5T and 50 Hz, and magnetic induction is 5000 A/m.

Technical Parameters of Silicon Steel

| Thickness(mm) | Trademark | Theoretical density (Kg/dm2) | Iron loss(W/Kg ) | Magnetic induction (T) | ||||

| 50Hz | 60Hz | |||||||

| 1.0T | 1.5T | 1.0T | 1.5T | 2500A /m | 5000A /m | |||

| 0.35 | 35W250 | 7.60 | 0.91 | 2.26 | 1.15 | 2.85 | 1.58 | 1.67 |

| 35W270 | 1.00 | 2.40 | 1.26 | 3.05 | 1.58 | 1.67 | ||

| 35W300 | 7.65 | 1.12 | 2.65 | 1.40 | 3.30 | 1.58 | 1.67 | |

| 35W360 | 1.24 | 2.75 | 1.54 | 3.40 | 1.59 | 1.68 | ||

| 35W400 | 1.40 | 3.18 | 1.75 | 3.95 | 1.59 | 1.67 | ||

| 35W440 | 7.70 | 1.70 | 3.75 | 2.10 | 4.70 | 1.58 | 1.67 | |

| 0.50 | 50W270 | 7.60 | 0.98 | 2.40 | 1.27 | 3.05 | 1.58 | 1.67 |

| 50W290 | 1.10 | 2.60 | 1.43 | 3.35 | 1.58 | 1.67 | ||

| 50W310 | 7.65 | 1.22 | 2.83 | 1.57 | 3.60 | 1.58 | 1.67 | |

| 50W350 | 1.26 | 2.91 | 1.60 | 3.70 | 1.58 | 1.67 | ||

| 50W400 | 1.45 | 3.30 | 1.83 | 4.15 | 1.59 | 1.67 | ||

| 50W470 | 7.70 | 1.63 | 3.57 | 2.05 | 4.50 | 1.59 | 1.67 | |

| 50W600 | 7.75 | 1.90 | 4.20 | 2.40 | 5.25 | 1.59 | 1.68 | |

| 50W700 | 7.80 | 2.30 | 5.00 | 2.95 | 6.40 | 1.62 | 1.70 | |

| 50W800 | 2.85 | 5.95 | 3.60 | 7.60 | 1.63 | 1.72 | ||

| 50W1000 | 7.85 | 3.30 | 6.70 | 4.10 | 8.60 | 1.66 | 1.74 | |

| 50W1300 | 3.60 | 7.45 | 4.50 | 9.40 | 1.67 | 1.75 | ||

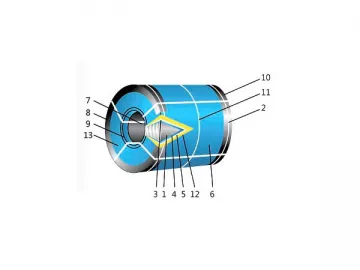

Packaging of Silicon Value

1. Steel coil

2. Lock catch

3. External edge protector

4. Anti-rust paper

5. Plastic film

6. Galvanized external guard board

7. Galvanized internal guard board

8. External edge protector

9. Internal edge protector

10. Strap in transverse direction

11. Strap in longitudinal direction

12. Plastic protective layer

13. Plastic end cap

Links:https://globefindpro.com/products/42576.html