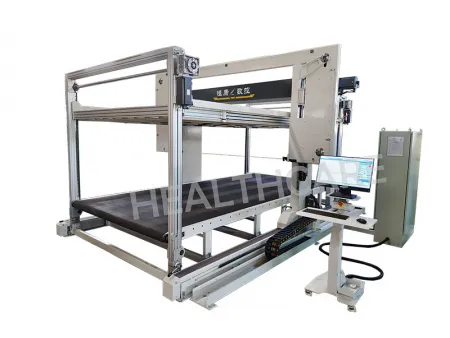

CNC Contour Cutting Machine with Vertical Blade, CNCHK-3

CNCHK-3 CNC foam cutting machine uses vertical blade for foam contour cutting with high speed and precision, which is a good alternative to foam die cutting machine. With cut-off and trimming unit, the CNC foam cutter is ideal for use in the production of automobile parts, upholstered furniture, and mattresses, as well as in the packaging and insulation industries. High cutting accuracy, dust-free cutting and maximized material efficiency are the main advantages of the foam processing machine.

CNCHK-3 CNC foam cutting machine uses vertical blade for foam contour cutting with high speed and precision, which is a good alternative to foam die cutting machine. With cut-off and trimming unit, the CNC foam cutter is ideal for use in the production of automobile parts, upholstered furniture, and mattresses, as well as in the packaging and insulation industries. High cutting accuracy, dust-free cutting and maximized material efficiency are the main advantages of the foam processing machine.

Contour Cutting Samples Contour cut foamContour cut foam

Contour cut foam

Applications Foam fabrication Upholstered furniture Mattress Packaging Automotive Household Materials PU foam High resilience foam Memory foam Latex foam Rebond foam Technical Data

| Max. block size | 3000*2200*1300mm |

| Toothed blade size | 1630*3*0.6mm |

| Cutting speed | 0-6.3m/min |

| Accuracy | ±0.5mm |

| Press roller | Yes |

| Operation system | Windows 7 |

| Computer | Industry computer |

Links:https://globefindpro.com/products/4357.html

-

Belt Driven Centrifugal Fan

Belt Driven Centrifugal Fan

-

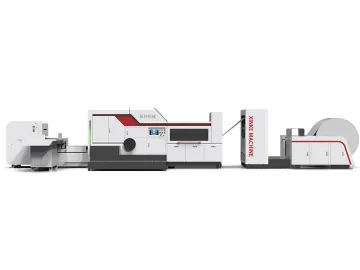

SOS Paper Bag Making Machine with 2 Color Flexo Printer XKR-220

SOS Paper Bag Making Machine with 2 Color Flexo Printer XKR-220

-

SP-300 Series Single Phase Programmable AC Power Source

SP-300 Series Single Phase Programmable AC Power Source

-

Flat and Satchel Paper Bag Making Machine XKJD-270

Flat and Satchel Paper Bag Making Machine XKJD-270

-

Block Rack System, CNCHK-11

Block Rack System, CNCHK-11

-

Block Bottom Bag Making Machine XKFD-330T/450T/540T

Block Bottom Bag Making Machine XKFD-330T/450T/540T

-

Fastwire CNC Contour Cutter, CNCHK-1

Fastwire CNC Contour Cutter, CNCHK-1

-

Pointed Bottom Bag Making Machine XKJD-400

Pointed Bottom Bag Making Machine XKJD-400

-

SOS Paper Bag Making Machine XKFD-220/280/330/450/540

SOS Paper Bag Making Machine XKFD-220/280/330/450/540

-

Horizontal Splitting Machine, CNCHK-QP

Horizontal Splitting Machine, CNCHK-QP

-

Portable Diesel Air Compressor, LY Series

Portable Diesel Air Compressor, LY Series

-

Refrigerated Air Dryer

Refrigerated Air Dryer