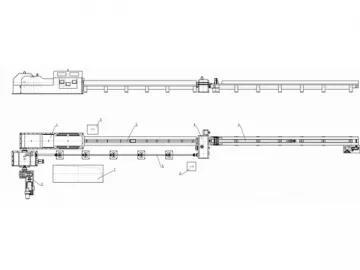

LG90-H Cold Pilger Mill

Nowadays, demand for seamless steel tubes is continuously increasing. A large number of high-quality steel tubes are needed in energy, transportation, oil, construction and machinery manufacturing industries. Our company can provide cold pilger mill with high rolling capacity to meet the increasing demand for seamless steel pipes.

Features

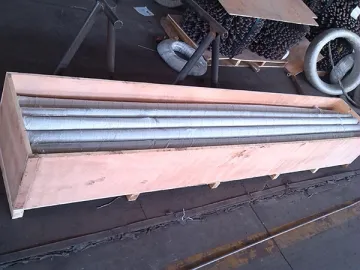

1. This cold rolling mill is suitable for the rolling processing of high precision ferrous and nonferrous metal seamless tubes whose diameters are in the range of 76~142mm.

2. This LG90-H cold pilger mill can reduce pipes' diameter by 45~114mm.

3. A gear box is assembled to the secondary transmission shaft system of our tube rolling equipment. In this way, the secondary transmission shaft system can work in a line and the transmission efficiency of the cardan shaft is increased.

4. The pneumatic clutch applied in our cold pilger mill allows the main motor to keep working continuously without stopping and starting frequently. It not only helps protect the motor against breaking down but also helps stabilize the power grid.

Detailed Parameters

| Order | Item | Parameter | Unit | |

| 1 | Hollow tube | Outer diameter | Ф76~Ф142 | mm |

| Wall thickness | 2.5~15 | mm | ||

| Length | ≤6000 | mm | ||

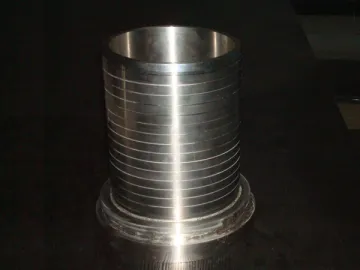

| 2 | Finished tube | Outer diameter | Ф45~Ф114 | mm |

| Wall thickness | 1.5~12 | mm | ||

| 3 | Maximum elongation coefficient | Stainless steel≤3 | ||

| 4 | Stroke length of machine frame | 1003 | mm | |

| 5 | Stroke number of machine frame | 58~82 | Time/min | |

| 6 | Rotation angle | 31°~26° ( Dual rotation) | ||

| 7 | Feeding amount | 3 ~12 (Dual feed) | mm | |

| 8 | Material loading mode | Side loading | ||

| 9 | Diameter of the roll | Ф450 | mm | |

| 10 | Main motor | Model | Z4-280-21 | |

| Power | 200 | kW | ||

| Revolving speed | 1000 | rpm | ||

| Power supply | 380V | |||

| 11 | Overall dimension | L×W×H | ≈2760×6000×2460 | mm |

Links:https://globefindpro.com/products/43839.html

-

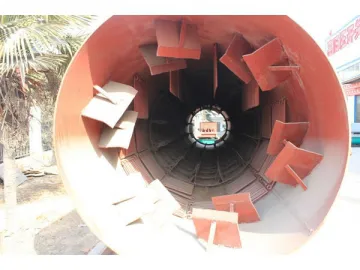

Drum Dryer for Sludge

Drum Dryer for Sludge

-

Hastelloy X Nickel Alloy

Hastelloy X Nickel Alloy

-

Stainless Steel Parts

Stainless Steel Parts

-

MA Series Heavy Duty Slurry Pump

MA Series Heavy Duty Slurry Pump

-

Hydraulic Briquetting Machine

Hydraulic Briquetting Machine

-

High Chrome Cast Iron Castings

High Chrome Cast Iron Castings

-

Coke Briquetting Machine

Coke Briquetting Machine

-

LG60-H Cold Pilger Mill

LG60-H Cold Pilger Mill

-

Heavy Machinery Simulation Trainer

Heavy Machinery Simulation Trainer

-

Drum Dryer for Sand

Drum Dryer for Sand

-

Charcoal Briquetting Machine

Charcoal Briquetting Machine

-

Drum Dryer for Coal

Drum Dryer for Coal