Hastelloy X Nickel Alloy

The Hastelloy X nickel alloy, with higher iron content, has favorable resistance to oxidation and corrosion combined with excellent creep and rupture strength at temperatures under 900℃. In addition to this, Hastelloy alloy X has great fabricability by cold and hot working and good weldability. This oxidation resistant alloy can be used for combustor components and other high temperature parts of aircraft engines, for long term use at temperature under 900℃ and short time use up to 1080℃.

| UNS | W. Nr |

| N06602 | 2.4665 |

Chemical Compositions of Hastelloy X Nickel Alloy

| Composition | Ni | Cr | Fe | Mo | W | Co | C | Mn | Si | S | Cu | Al | Ti | |

| Content (%) | Min. | Bal. | 20.5 | 17.0 | 8.0 | 0.2 | 0.5 | 0.05 | ||||||

| Max. | 23.0 | 20.0 | 10.0 | 1.0 | 2.5 | 0.15 | 1.0 | 1.0 | 0.015 | 0.5 | 0.15 | 0.5 | ||

| Tensile Strength (σb/MPa) | Yield Strength (σp0.2/MPa) | Elongation (σ5/%) |

| 690 | 275 | 30 |

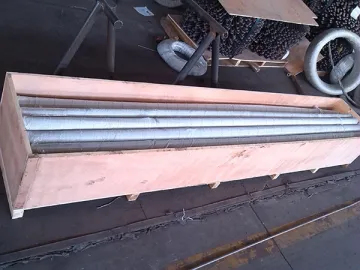

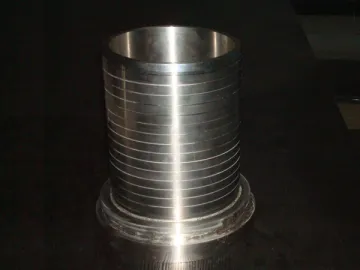

Product Forms and Standards

| Bar | Sheet/Strip | Wire | Pipe |

| ASTM B572 | ASTM B435 | ASTM B166 | ASTM B622 ASTM B619 ASTM B626 |

Scan QR to Read

Links:https://globefindpro.com/products/43841.html

Links:https://globefindpro.com/products/43841.html

Recommended Products

-

Stainless Steel Parts

Stainless Steel Parts

-

MA Series Heavy Duty Slurry Pump

MA Series Heavy Duty Slurry Pump

-

Hydraulic Briquetting Machine

Hydraulic Briquetting Machine

-

High Chrome Cast Iron Castings

High Chrome Cast Iron Castings

-

Aluminum Briquetting Machine

Aluminum Briquetting Machine

-

MF Series Froth Pump

MF Series Froth Pump

-

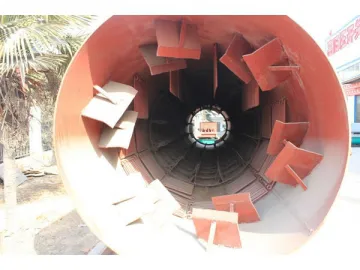

Drum Dryer for Sludge

Drum Dryer for Sludge

-

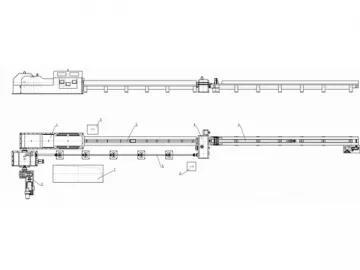

LG90-H Cold Pilger Mill

LG90-H Cold Pilger Mill

-

Coke Briquetting Machine

Coke Briquetting Machine

-

LG60-H Cold Pilger Mill

LG60-H Cold Pilger Mill

-

Heavy Machinery Simulation Trainer

Heavy Machinery Simulation Trainer

-

Drum Dryer for Sand

Drum Dryer for Sand

Hot Products