Horizontal Vacuum Furnace with Molybdenum Heating

The horizontal vacuum furnace with molybdenum heating has mainly been seen in manufacturing enterprises. In high vacuum environment or shielding gas, this metal heat treating equipment delivers annealing, sintering and degassing treatment to metals.

This vacuum heat treatment furnace also finds application to produce dehydroxyl clear fused quartz, as well as vacuum brazing of metal materials. This vacuum furnace is available in vertical and horizontal layout. Based on different size of working area, we offer various models accordingly.

Structure

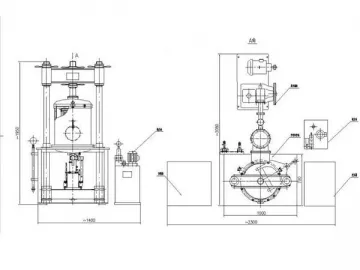

1. This powder metallurgy equipment consists of furnace cover, furnace body, furnace bottom, vacuum system and electric control system, etc.

2. Water cooling device comes in dual-layer structure for furnace cover, body and bottom. The inner side of the device adopts stainless steel to keep furnace shell temperature under 60℃. Furnace cover is manually open and is fitted with an inspection window.

Furnace body of this horizontal vacuum furnace also has an inspection window on one side and features thermal insulation shield made from metal. Heating component involves molybdenum wire or belt. Furthermore, thermocouple is available on the furnace body for automatic temperature control.

3. Vacuum system is equipped with primary-secondary pump which is the combination of oil diffusion pump and mechanical pump. ZJ-150 Roots pump can be added to form primary-secondary-tertiary pumping system. The mechanical pump comes with electromagnetic exhaust valve to prevent oil back streaming in case of power failure. The vacuum unit is born with exhaust valve and inlet valve.

4. Temperature control circuit includes large current transformer, voltage regulator and temperature control instrument. In order for ensured safety, alarm system is available on water shortage, over current and over temperature for maximal protection.

5. Electric control system equipped in our horizontal vacuum furnace consists of PLC and colorful mimic panel, performing automatic switch between high and low vacuum, as well as air charging and discharging. Multiple protective alarms and interlocking function are available.

Technical data| Model | Rated power | Max. working temperature | Working area size | Max. vacuum degree | Note |

| EF-25-16 | 30kW | 1600℃ | 50 × 200 | 5×10-3 Pa | Single phase |

| EF-36-10 | 36kW | 1000℃ | 300 × 400 | 5×10-3 Pa | 3 phase |

| EF-40-16 | 40kW | 1600℃ | 200 × 280 | 5×10-3 Pa | 3 phase |

| EF-45-15 | 45kW | 1500℃ | 340 × 400 | 5×10-3 Pa | 3 phase |

| EF-160-13 | 160kW | 1300℃ | 730 × 540 × 940 | 5×10-3 Pa | 3 phase |

Supporting Equipment Steel Belt Reduction Furnace Sinter-HIP Furnace Vacuum Induction Melting Furnace

Related Names

Horizontal Vacuum Equipment | Molybdenum Wire Heating Oven

Links:https://globefindpro.com/products/43921.html

-

Corrosion Resistant Self Priming Pump

Corrosion Resistant Self Priming Pump

-

Vacuum Arc Remelting Furnace

Vacuum Arc Remelting Furnace

-

Suspension Melting Furnace

Suspension Melting Furnace

-

Pre-vacuum Atmosphere Sintering Furnace

Pre-vacuum Atmosphere Sintering Furnace

-

Vacuum Gas Quench Furnace

Vacuum Gas Quench Furnace

-

DIN 24255 Centrifugal Pump

DIN 24255 Centrifugal Pump

-

Steel Belt Reduction Furnace

Steel Belt Reduction Furnace

-

Mesh Belt Sintering Furnace

Mesh Belt Sintering Furnace

-

HLJB Series Horizontal Multistage Centrifugal Pump

HLJB Series Horizontal Multistage Centrifugal Pump

-

Vacuum Hot Press Furnace

Vacuum Hot Press Furnace

-

Pusher Reduction Furnace

Pusher Reduction Furnace

-

Microwave Vacuum Sintering Furnace

Microwave Vacuum Sintering Furnace