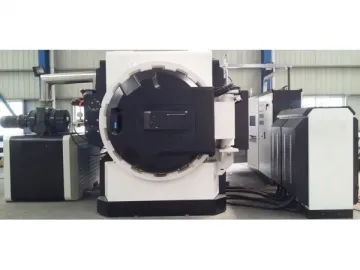

Vacuum Gas Quench Furnace

The vacuum gas quench furnace is the cutting-edge heat treatment equipment featuring prominent properties and unique design. This high pressure gas quench furnace is the industry-proven solution to gas quench and bright annealing of high precision alloy steel parts such as high-speed steel, die steel, alloy steel and titanium alloy, etc. Our industrial furnace is also applicable for sintering and fast cooling of magnetic materials.

Advantage

1. Featuring annular radiator made from cooper tube in large diameter, our vacuum gas quench furnace delivers fast cooling effect.

2. Air nozzle is 360° deployed around heating chamber uniformly. As a result, optimal cooling effect ensures minimized deformation on workpiece.

3. Heating component is also 360° placed around the heating chamber, ensuring high energy efficiency, low heat loss and balanced heating effect.

4. This metal heat treatment equipment adopts new type of composite hard felt/metal shield as thermal insulation plate with heating function. Customers avail from outstanding resistance against heat, pressure and air scour, as well as prolonged service life.

5. Flexible programming input and stable mechanical performance ensure exceptional stability and low maintenance. Integrated safety system and failure alarms facilitate reliability.

Structure

1. Comprehensive and standard modular design has been poured into the manufacture of our vacuum gas quench furnace. The whole structure comprises steel furnace body, composite thermal insulation shield, heating rod, high-speed air flow channel, large power motor with fan, high efficiency gas exchanging device, thermal inflation system, vacuum system, cooling water system and electric control system.

2. The maximal inflation pressure is 1.0Mpa as absolute pressure, and is allowed to be continuously adjusted from 0.2 to 1.0MPa.

3. Hearth is made up of either graphite or metal. Heating component falls into graphite and molybdenum.

Technical data| Model | EF-VQG50 | EF-VQG100 | EF-VQG200 | EF-VQG300 | EF-VQG400 |

| Rated feeding capacity (kg) | 50 | 100 | 200 | 300 | 400 |

| Max. temperature (℃) | 1350 | ||||

| Temperature accuracy (℃) | ≤±5 | ||||

| Rated power (kW) | 50 | 90 | 120 | 150 | 180 |

| Rated voltage of power supply (V) | 380 | ||||

| Rated heating voltage (V) | Depends on design Front transformer is available in every design. | ||||

| Max. vacuum degree (Pa) | ≤6.67 (Empty furnace in cool status) | ||||

| Vacuum pressure rising rate (Pa/24h) | ≤50 | ||||

| Quench pressure | ≤1.0Mpa (absolute pressure) | ||||

| Working zone dimension (mm) | 300 × 300 × 400 | 300 × 300 × 500 | 450 × 400 × 670 | 450 × 400 × 850 | 600 × 600 × 1000 |

| Temperature control system | Shimaden programmable controller | ||||

| Vacuum system | Rotary vane vacuum pump Roots pump | ||||

Retrofit

1. Built-in fast cooling system

2. PLC and touch screen

3. Based on requirements on vacuum degree, oil diffusion pump can be added and maximal vacuum degree reaches 6.7×10-4 Pa.

Supporting Equipment Amorphous Alloy Powder Equipment High Temperature Graphite Furnace Vacuum Arc Remelting Furnace

Related Names

Gas Quenching Stove | Gas Quenching Vacuum Furnace | Vacuum Quench Furnace

Links:https://globefindpro.com/products/43926.html

-

DIN 24255 Centrifugal Pump

DIN 24255 Centrifugal Pump

-

Vacuum Brazing Furnace

Vacuum Brazing Furnace

-

Centrifugal Slurry Pump

Centrifugal Slurry Pump

-

Large Vertical High Temperature Vacuum Furnace

Large Vertical High Temperature Vacuum Furnace

-

Sinter-HIP Furnace

Sinter-HIP Furnace

-

High Temperature Induction Sintering Furnace

High Temperature Induction Sintering Furnace

-

Pre-vacuum Atmosphere Sintering Furnace

Pre-vacuum Atmosphere Sintering Furnace

-

Suspension Melting Furnace

Suspension Melting Furnace

-

Vacuum Arc Remelting Furnace

Vacuum Arc Remelting Furnace

-

Corrosion Resistant Self Priming Pump

Corrosion Resistant Self Priming Pump

-

Horizontal Vacuum Furnace with Molybdenum Heating

Horizontal Vacuum Furnace with Molybdenum Heating

-

Steel Belt Reduction Furnace

Steel Belt Reduction Furnace