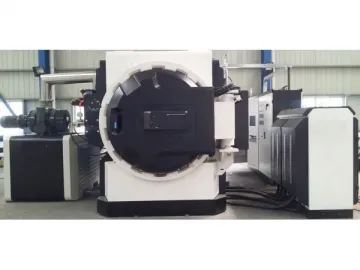

Sinter-HIP Furnace

The sinter-HIP furnace combines degreasing, vacuum sintering, atmosphere sintering, partial pressure sintering and pressure sintering in one production equipment. This vacuum degreasing and sintering equipment excels at degreasing of high performance hard alloy materials via positive and negative pressure with forming agents such as paraffin and PEG, etc. The atmosphere sintering involves the utilization of all kinds of industrial gases such as hydrogen and methane, as well as other mixed gases.

This vacuum dewaxing and sintering furnace is highly distinguished by exceptional automation, flexibility and ease of operation. Customers are allowed to enjoy both manual and automatic control. In addition, our sinter-HIP furnace also features locking function, remote control and remote diagnosis, etc.

Technical data of sinter-HIP furnace| Model | 1MPA | 6MPA | 10MPA |

| Furnace size | 350´350´1200 500´500´1800 | 350´350´1200 400´400´1200 500´500´1800 | 350´350´1200 400´400´1200 500´500´1800 |

| Nominal running times | 6000 times | 6000 times | 6000 times |

| Max. working temperature | 1600℃ | 1600℃ | 1600℃ |

| Max. working pressure | 10bar | 60bar | 100bar |

| Air leakage rate | 3Pa/h (Average for cold, empty and dry hearth in 24h) | 3Pa/h (Average for cold, empty and dry hearth in 24h) | 3Pa/h (Average for cold, empty and dry hearth in 24h) |

| Pumping rate | In 30 minutes after pump start | In 30 minutes after pump start | In 30 minutes after pump start |

| Vacuum pimp | Pump with slide valve, Roots pump | Pump with slide valve, Roots pump | Pump with slide valve, Roots pump |

| Wax collecting rate | 98% | 98% | 98% |

| Pressure time | 15-30 minutes (settable) | 15-30 minutes (settable) | 15-30 minutes (settable) |

| Cooling time (full furnace) | 4h | 5h/6h/8-10h | 6h/8-10h |

| Temperature uniformity | ±0.4KAM | ±0.4KAM | ±0.4KAM |

| Cooling water temperature | 30℃(suggested) | 30℃(suggested) | 30℃(suggested) |

| Cooling water flow rate | 320L/min | 320L/min | 320L/min |

| Power supply | 3 phase, 5 wire AC380V±10PHZ | 3 phase, 5 wire AC380V±10PHZ | 3 phase, 5 wire AC380V±10PHZ |

| Power supply in control cabinet | Single phase AC210V-250V/50H | Single phase AC210V-250V/50H | Single phase AC210V-250V/50H |

| Heating power | 220KVA/300KVA | 260KVA/280KVA/400KVA | 300KVA/340KVA/520KVA |

| Other | 20KVA/42.5KVA | 30.5KVA/30KVA/46.5KVA | 30KVA/30KVA/46.5KVA |

| Measuring method | Wre5-26 thermocouple | Wre5-26 thermocouple | Wre5-26 thermocouple |

| Temperature control | Three-zone | Three-zone/four-zone | Three-zone/four-zone |

| Working area | 350´350´1200 500´500´1200 | 350´350´1200 400´400´1200 500´500´1800 | 350´350´1200 500´500´1800 |

| Functions available | Vacuum sintering, negative pressure dewaxing, positive pressure dewaxing and dehydrogenation, partial pressure sintering, atmosphere sintering, pressure sintering, fast cooling | Vacuum sintering, negative pressure dewaxing, positive pressure dewaxing and dehydrogenation, partial pressure sintering, atmosphere sintering, pressure sintering, fast cooling | Vacuum sintering, negative pressure dewaxing, positive pressure dewaxing and dehydrogenation, partial pressure sintering, atmosphere sintering, pressure sintering, fast cooling |

| Furnace body weight | 8 tons/12 tons | 15 tons/17 tons/22 tons | 24 tons/34 tons |

| Injected gas | Argon, hydrogen, nitrogen, methane | Argon, hydrogen, nitrogen, methane | Argon, hydrogen, nitrogen, methane |

Supporting Equipment Amorphous Alloy Powder Equipment High Temperature Graphite Furnace Vacuum Induction Melting Furnace

Related Names

Sintering Furnace | High Temperature Sinter Furnace | Hot Isostatic Pressing

Links:https://globefindpro.com/products/43931.html

-

High Temperature Induction Sintering Furnace

High Temperature Induction Sintering Furnace

-

Glass Melting Furnace

Glass Melting Furnace

-

D Series Horizontal Multistage Centrifugal Pump

D Series Horizontal Multistage Centrifugal Pump

-

Nitrogen/Hydrogen Generator by Ammonia Decomposition

Nitrogen/Hydrogen Generator by Ammonia Decomposition

-

Mesh Belt Atmosphere Brazing Furnace

Mesh Belt Atmosphere Brazing Furnace

-

Self Priming Oil Pump

Self Priming Oil Pump

-

Large Vertical High Temperature Vacuum Furnace

Large Vertical High Temperature Vacuum Furnace

-

Centrifugal Slurry Pump

Centrifugal Slurry Pump

-

Vacuum Brazing Furnace

Vacuum Brazing Furnace

-

DIN 24255 Centrifugal Pump

DIN 24255 Centrifugal Pump

-

Vacuum Gas Quench Furnace

Vacuum Gas Quench Furnace

-

Pre-vacuum Atmosphere Sintering Furnace

Pre-vacuum Atmosphere Sintering Furnace