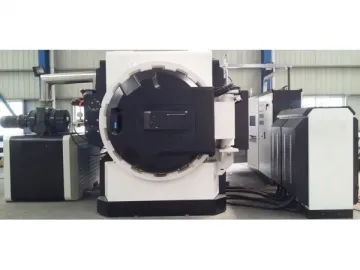

Large Vertical High Temperature Vacuum Furnace

The large vertical high temperature vacuum furnace is the kind of heat treatment equipment working in vacuum environment. This metal powder sintering furnace has been extensively applied to ceramic sintering, refractory metal smelting, annealing and university labs. The maximal furnace temperature reaches 2100℃, making our powder metallurgy equipment to be ideal for annealing, drying and heat treatment.

Advantage

1. This high temperature vacuum furnace involves the utilization of resistance heating method, generating no noise. Shimaden programmable controller is employed for ultimate temperature accuracy and promoted electricity efficiency.

2. Vertical layout offers minimal floor space, and shows excellence in terms of lifting, horizontal deployment and feeding.

3. Fully automatic control is realized via intuitive touch screen. PLC provides interlocking function. Furthermore, audile and visual alarms are triggered on overpressure, overheat or too high water temperature, resulting in guaranteed safety.

Technical data| Model | EF -VSL120 | EF-VSL220 | EF-VSL280 | EF-VSL360 | EF-VSL450 |

| Rated furnace temperature (℃) | 2100 | ||||

| Max. furnace temperature (℃) | 2150 | ||||

| Temperature accuracy(℃) | ≤±5 | ||||

| Rated power (kW) | 120 | 220 | 280 | 360 | 450 |

| Rated voltage of power supply (V) | 380 | ||||

| Rated heating voltage (V) | Depends on design External transformer is available in all design. | ||||

| Max. vacuum degree (Pa) | ≤6.67 (Empty furnace in cool environment) | ||||

| Pressure rising rate (Pa/24h) | ≤50 | ||||

| Working area dimension (mm) | Φ600×1000 | Φ800×1200 | Φ1000×1600 | Φ1200×1800 | Φ1400×2500 |

| Temperature control system | Shimaden programmable controller | ||||

| Vacuum system | Rotary vane vacuum pump Roots vacuum pump | ||||

Retrofit

1. PLC and touch-screen display

2. Oil diffusion pump is optional, resulting in 6.7×10-4Pa maximal vacuum degree.

3. Slight-negative pressure sintering system delivers constant pressure for sintering to facilitate product compactness and quality.

Supporting Equipment Vacuum Gas Atomization Powder Manufacturing Equipment Mesh Belt Atmosphere Brazing Furnace PSA Nitrogen Generator

Related Names

Vacuum Equipment | Industrial Vacuum Oven | Vacuum Kiln

Links:https://globefindpro.com/products/43930.html

-

Sinter-HIP Furnace

Sinter-HIP Furnace

-

High Temperature Induction Sintering Furnace

High Temperature Induction Sintering Furnace

-

Glass Melting Furnace

Glass Melting Furnace

-

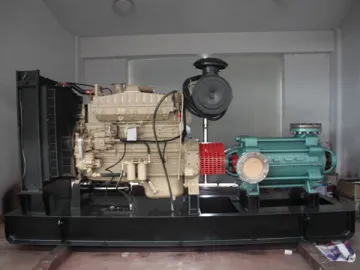

D Series Horizontal Multistage Centrifugal Pump

D Series Horizontal Multistage Centrifugal Pump

-

Nitrogen/Hydrogen Generator by Ammonia Decomposition

Nitrogen/Hydrogen Generator by Ammonia Decomposition

-

Mesh Belt Atmosphere Brazing Furnace

Mesh Belt Atmosphere Brazing Furnace

-

Centrifugal Slurry Pump

Centrifugal Slurry Pump

-

Vacuum Brazing Furnace

Vacuum Brazing Furnace

-

DIN 24255 Centrifugal Pump

DIN 24255 Centrifugal Pump

-

Vacuum Gas Quench Furnace

Vacuum Gas Quench Furnace

-

Pre-vacuum Atmosphere Sintering Furnace

Pre-vacuum Atmosphere Sintering Furnace

-

Suspension Melting Furnace

Suspension Melting Furnace