CDH-90 Toilet Roll Packing Machine

Functional Features

1. The CDH-90 toilet roll packing machine comes with simple structure, small vibration, low noise, long service life, strong wear resistance and two frequency converters. It is user and maintenance friendly.

2. It is designed with dual film supporting mechanisms, allowing for rapid film replacement.

3. Ultra large LCD with touch screen and human-machine interface make operation easier and more convenient.

4. Stepless variable frequency speed regulation is available for this toilet paper machine. Thus, bag length and packing speed can be arbitrarily adjusted, and packing film is also saved.

5. Our toilet roll packing machine also adopts high-precision magic eye for automatic and reliable tracking. Therefore, correct sealing position is sound guaranteed.

6. Sealing temperature is independently controlled.

7. We also equip this toilet roll packer with code printer, and printing position can be freely set.

8. Our toilet paper roll wrapper is CE certified.

9. Pneumatic control system and conveying belt are adopted. Hence, the entire machine runs stably and reliably, providing artistic packaging.

Technical Parameters

| Power supply | 220V, 50Hz |

| General power | 3.2KW |

| Motor power | 0.4, 0.75KW |

| Packing speed | 50-120 bags/min. |

| Finished bag size | Diameter of paper roll: 90-120mmLength: 90-180mm (It is adjustable, but needs to change model accordingly.) |

| Working noise | ≤78dB |

| Qualification percentage for finished bag | ≥97% |

| Sealing pressure | 15 (Newton/mm2) |

| Max. film width | 400mm |

| Packing film | OPP, CPP |

| Packing film thickness | 0.020mm-0.035mm |

| Machine size | 5500×1005×1750mm (L×W×H) |

| Machine weight | 900kg |

Operation Process

This toilet roll packing machine can be coupled with toilet roll slitter rewinder. After paper rolls are conveyed to the packer, the packer will successively perform transverse and longitudinal sealing for single paper roll. Finally, you will get finished paper rolls with exquisite package.

Pictures of Finished Product

Links:https://globefindpro.com/products/44038.html

-

CD-2030 5~30pcs Semi Automatic Wet Wipe Machine

CD-2030 5~30pcs Semi Automatic Wet Wipe Machine

-

CDH-236 Facial Tissue Box Packaging Machine

CDH-236 Facial Tissue Box Packaging Machine

-

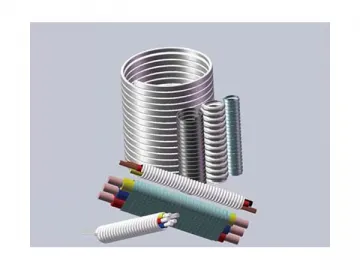

Power Cable Steel Wire Armoring Machine

Power Cable Steel Wire Armoring Machine

-

CD-160N Automatic Single Piece Wet Wipe Machine

CD-160N Automatic Single Piece Wet Wipe Machine

-

CDH-180J Paper Tube Machine

CDH-180J Paper Tube Machine

-

CDH-180-4L Facial Tissue Machine

CDH-180-4L Facial Tissue Machine

-

CDH-200-2 Facial Tissue Machine

CDH-200-2 Facial Tissue Machine

-

Three-layer Cross-linked Cable Extrusion Line

Three-layer Cross-linked Cable Extrusion Line

-

KRH Interlock Strip Armoring Machine

KRH Interlock Strip Armoring Machine

-

CDH-1575-GS Fully Automatic Kitchen Paper Towel Machine

CDH-1575-GS Fully Automatic Kitchen Paper Towel Machine

-

CGB Skip Strander

CGB Skip Strander

-

CDH-200-400 Two Color Napkin Machine

CDH-200-400 Two Color Napkin Machine