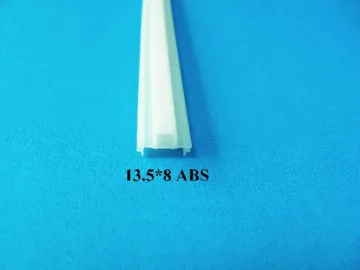

Nylon 6 Tube and Extrusion Profiles

Nylon 6 has been proved to be the most versatile engineering plastic on markets. This PA (polyamide) 6 offers the best in terms of toughness even at low temperature.

Grounded on extremely great properties, our nylon 6 tube and extrusion profile have been widely applied to all kinds of machinery structures and spare parts.

Strength

1. High toughness and rigidity

2. Remarkable impact resistance and notch strength

3. Impressive thermal stability and stress-cracking resistance

4. Excellentevaporativity

5. Superb abrasion resistance

5. Self-lubricating, low coefficient of friction and noise generation

6. Good chemical resistance against organic solvents and fuel

7. Considerable electrical insulation, easy to be printed and colored

8. Non-toxic

Limit

1. Low dimensional stability

2. Electrical and mechanical strength will be impacted by moisture absorption or thermal expansion

3. Poor resistance to acids, thus cannot be applied to acid dye or too many acid materials

4. Unsatisfactory resistance to light and pollutions

Application

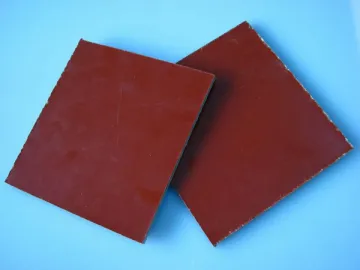

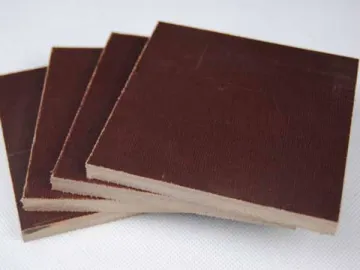

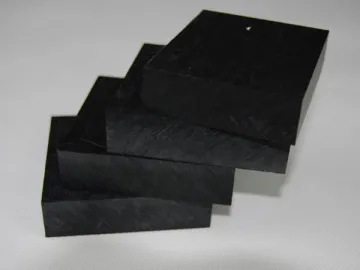

1. Fan blade, structural panel, wear pad and air deflector

2. Automobile parts such as lock, chain wheel and housing, etc.

3. Bearing, gear, caster and pump body

4. Sliding track, roller and hardware parts

Specification

| Density | 1.15 to 1.20 g/cm3 |

| Hardness | Shore D 83 |

| Formation | Extrusion and rotational molding |

| Working temperature | -40°C to 110°C |

| Certificates | CTI, SGS, RoHS |

| Product code | 3920920000 |

| Production capacity | 200 tons per month |

| Payment terms | TT, L/C, Western Union |

| Delivery cycle | About 15 working days |

| Package | By pallets |

| Added service | Slitting and machining |

Dimension

| Nylon 6 tube | ||

| Outside diameter (mm) | Wall thickness (mm) | Length (mm) |

| 4 to 20 | 0.75 to 5 | 1000 or other length |

| 20 to 400 | 10 to 200 | 500, 1000 |

Note

1. Other choices of sizes, colors and grades are customizable.2. Length, width, thickness and diameter tolerance are slightly different due to inevitable error occurred in production process.

Links:https://globefindpro.com/products/44443.html