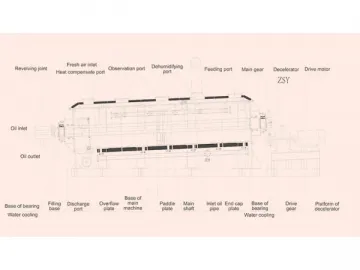

HZG Rotary Drum Dryer

Overview

The HZG rotary drum dryer can be used for hard magnetic ferrite powder pre-sintering. It is mainly composed of main kiln, gearing, cooling pipe, fuel system, electrical control system, secondary inlet air device, exhaust and dedusting device, as well as pre-sintering kiln. Meanwhile, this rotary-drum dryer integrates multiple functions, such as over temperature alarm, overload alarm, automatic temperature control, adjustment of oxygen inside kiln, etc.

Working Principle

After entering the rotary drum dryer, materials are mixed under the action of shoveling plate, and then uniformly distributed, thus having full contact with convective hot air. This procedure accelerates heat and mass transfer and thereby expedites material drying. Afterwards, the already dried materials will move to star-type discharge valve, and then are discharged in controllable way.

Application

The rotary drum drying equipment can be applied to cement, metallurgy, mines, chemical engineering and other industries for drying materials of large granule and specific gravity, such as the ore, blast furnace slag, coal, metal powder, phosphatic fertilizer, the ammonium sulfate, etc.

Our rotary drum dryer is also applicable for powdery or granular materials with specific requirements, such as the foaming agent, vinasse, light calcium carbonate, activated clay, magnetic powder, plumbago, the drug residue, etc.

Features

1. Our rotary drum dryer suits for low temperature, large-scale and continuous material drying.

2. Due to high mechanization level, its production capacity is extremely large.

3. Fluid resistance is small, thus energy consumption is less.

4. This rotary-drum-dryer boasts strong material adaptability.

5. Stable operation, low operation cost and excellent drying uniformity will make you feel very satisfied with this rotary drum dryer.

Technical Parameters

| Heating mode | Direct heating, direct flow | Direct heating, direct flow | Direct heating, direct flow | Direct heating, direct flow | Compound heating | Compound heating |

| Material variety | Ore | HP foaming agent | Blast furnace slag | Ammonium sulfate | Phosphatic fertilizer | Coal |

| Drying capacity (kg/h) | 1000 | 466 | 15000 | 20000 | 12000 | 5000 |

| Preliminary water content (%) | 30 | 13 | 6 | 1.5 | 5 | 6.5 |

| Final water content (%) | 15 | 0.3 | 1 | 0.1 | 0.1 | 0.1 |

| Average particle size (mm) | 6.5 | 0.05 | 4.7 | 0.5-1.7 | 0.5 | 5 |

| Material bulk specific weight (kg/m3) | 770 | 800 | 1890 | 1100 | 5500 | 750 |

| Hot air capacity (kg/h) | 39000 | 5400 | 10750 | 9800 | 6500 | 16000 |

| Inlet air temperature (°C) | 600 | 165 | 500 | 180 | 650 | 570 |

| Material outlet temperature (°C) | 42 | 100 | 70 | 80 | 75 | |

| Heating | Coal gas | Steam and electric heating | Heavy oil | Hot air furnace by using coal | Heavy oil | Heavy oil |

| Material charge coefficient | 6.3 | 7 | 7.5 | 7.8 | 18 | |

| Rotating speed (rpm) | 4 | 4 | 3.5 | 3 | 4 | 2 |

| Inclination | 0.04 | 0.005 | 0.03 | 0.05 | 0.05 | 0.043 |

| Shoveling plate number | 12 | 24 | 12 | 22 | 8, internal tank outside16, external tank inside | 6, internal tank outside12, external tank inside |

| Drying diameter (m) | 2 | 1.5 | 2 | 2.3 | External tank: 2Internal tank: 0.84 | External tank: 2.4Internal tank: 0.94 |

| Drying length (m) | 20 | 12 | 17 | 15 | 10 | 16 |

| Driving power (KW) | 22 | 7.5 | 15 | 11 | 11 | 15 |

Links:https://globefindpro.com/products/44502.html