Flat & Satchel Paper Bag Machine

Flat and satchel paper bag machine is designed on the basis of increasing needs from food bag industry home and abroad. As a prestigious handbag making solution supplier, our reputation has been built on the innovation and new production development. We are excellent at offering outstanding product that fits a wide range of applications.

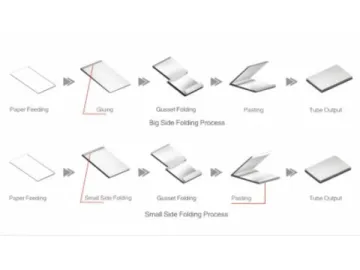

FSB1600 roll-fed high-speed packaging equipment is significantly distinguished by exemplary ability to encompass whole production process including glue dispensing, patching, edge gluing, tube forming, cutting, bottom gluing, bag forming and counting. This handbag maker intrinsically processes natural or printed roll paper into fabulous paper bag applicable for industries of fast food, commercial products, gifts, mails, liquids and medicine.

Our flat and satchel paper bag machine is renowned by optimal structure and ease of use. Users are provided with high-speed central processing unit and touch-screen display, as well as servo motor to control machine speed. In addition, users are allowed to choose single or double channel production system accordingly. The maximal machine speed reaches 1000pcs/min. As a result, our product is the ideal alternative to imported equipment.

Forming unit

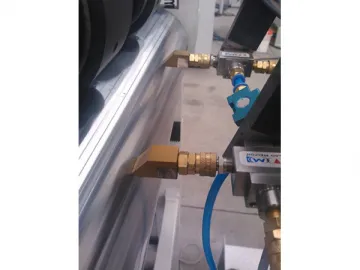

Valco cold glue dispensing system

for double channel production

system BST Web Guiding Control System

Stacker

Main screen available

in English display

Advantage

1. Feeding table is fitted with automatic tension control.

2. Automatic fault detection

3. Glue dispensing device added

4. Central cutting applied to double channel production

5. SUNHOPE rotary cutting blade

6. Belt transporting device is used to maintain the relationship between cutting rotary drum and folding rotary drum, ensuring the minimal value of bag bottom.

7. Additional oil-powered main transmission device is available and the oil is supplied by the pump.

8. Paper bag is transferred vertically, and a programmable counter is utilized for adjust bag counting.

9. Servo feeding system, which is equipped with a programmable device (with no transmission gear) to adjust cutting length, allows for pre-printing materials that has photoelectric detector.

10. Optional patch unit

Note

1. Not all manner of bag width and edge can be applied to this machine. Please feel free to contact SUNHOPE for information of special combinations.

2. When applying double channel production system, bag width is susceptible to surface width and placement. Please contact SUNHOPE for detailed information.

Specification

| Single channel production | Bag width (without edge) | 1.5 to 14.5 inches | 39 to 368mm |

| Bag width (with edge) | 2 to 12.5 inches | 51 to 317mm | |

| Total edge | 0.5 to 5 inches | 13 to 127mm | |

| Double channel production | Bag width (without edge) | 1.5 to 7 inches | 39 to 177mm |

| Bag width (with edge) | 2 to 5.75 inches | 51 to 146mm | |

| Total edge | 0.5 to 3 inches | 13 to 76mm | |

| Cut-off length range | 4 to 11.50 inches | 102 to 292mm | |

| Max. material width | 30 inches | 762 mm | |

| Max. material diameter | 47.2 inches | 1200 mm | |

| Paper basis weight range | 20 to 40 pounds | 30g/m2 to 65g/m2 | |

| Min. edge sealing | 0.625 inches | 16mm | |

| Minimal side wing above finished die = edge sealing overlap edge sealing compensation | 1 inch | 25mm | |

Links:https://globefindpro.com/products/44545.html

-

Magnetic Separator

Magnetic Separator

-

Plastic Pipe Shredder

Plastic Pipe Shredder

-

Vibrating Screen

Vibrating Screen

-

Envelope Making Machine (Pocket Envelope, model POCKET120)

Envelope Making Machine (Pocket Envelope, model POCKET120)

-

ZB1300B-1 Paper Bag Forming Machine

ZB1300B-1 Paper Bag Forming Machine

-

ZB960C-330 Sheet-Feeding Automatic Paper Bag Making Machine

ZB960C-330 Sheet-Feeding Automatic Paper Bag Making Machine

-

Lead-acid Battery Recycling Plant

Lead-acid Battery Recycling Plant

-

ZJ40 Skid-Mounted Drilling Rigs

ZJ40 Skid-Mounted Drilling Rigs

-

Aluminium Recycling Plant (Recycling Aluminum from Aluminum Composite Panels)

Aluminium Recycling Plant (Recycling Aluminum from Aluminum Composite Panels)

-

Plastic Film Recycling Line

Plastic Film Recycling Line

-

RL3NB Series Triplex Mud Pump

RL3NB Series Triplex Mud Pump

-

Heavy Duty Granulator

Heavy Duty Granulator