SBH150 Automatic Block Bottom Paper Bag Machine

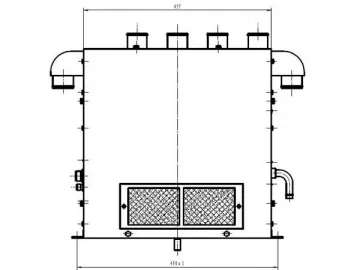

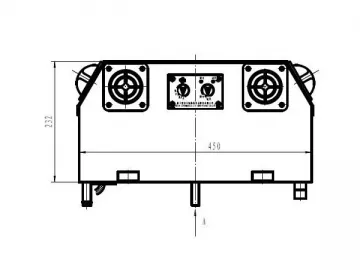

The performance capabilities of the SBH150 automatic block bottom paper bag machine are particularly well suited for producing small to medium-sized carrier bag and block bottom paper bags with 40gsm-50gsm kraft paper. Depending upon paper bag making machine specifications, the bags can consist of 1, 2 or 3 plies.

Standard features of the block bottom paper bag machine include servo technology and are ready for additional units in terms of electrical control. Servo film patching unit, servo window die cutting unit, and servo two layer unit can be introduced to this roll-fed paper bag making equipment to meet the needs for customers producing window bags, two piles bags, etc.

Optional equipment

1-2 color flexo printer unit

Servo window die cutter unit

Servo film patching unit

Servo two layer unit

Bag Production

Two-layer block

bottom ba

Block bottom bag

with see-through

window

Block bottom bag

Cut-off handle

block bottom bag

Specification

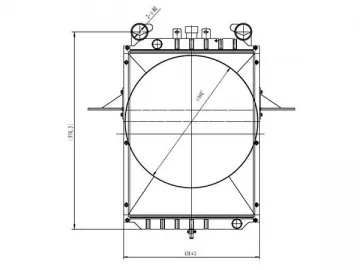

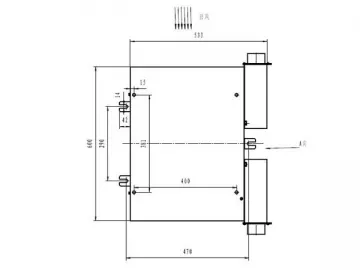

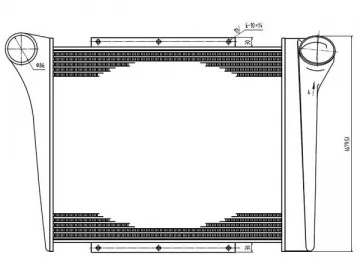

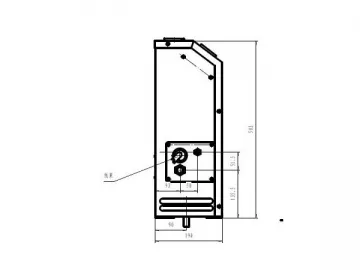

| Model | SBH150 |

| Material width | 295 to 640mm |

| Cut-off length | 195 to 385mm |

| Bag width | 80 to 200mm |

| Bottom width | 50 to 100mm |

| Paper basis weight | 38 to 130GSM |

| Max. roll diameter | <= 1200mm |

| Roll inner diameter | Φ76mm |

| Max. production capacity | 250pcs/min |

| Total power | 9kW |

| Machine weight | About 5500kg |

| Machine dimension | 8600mm × 1500mm × 1650mm |

In 2013, our company attended The 8th Beijing International Printing Technology Exhibition. Our SBH150 processed 45g Manila paper with 160 to 180pcs/min of stable machine speed.

Links:https://globefindpro.com/products/44591.html