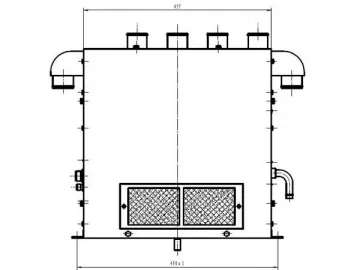

Air Blast Cooler

The air blast cooler is mainly composed of the radiator core, wind hood, fan, mounting bracket, flange connection, and the drive unit.

A compact structure typically allows the radiator core to have a high pressure resistance, great heat dissipation performance, and maximum reliability. Made of aluminum alloy, such a core has relatively light weight.

The air cooler incorporates a fan and fan drive. The fan comes with nylon fan blades that are resistant to weathering and static pressure. The fan drive is either a reliable, long-lasting electric motor or hydraulic motor.

Compact layout, high cooling efficiency, and easy installation are three major benefits of our air cooled radiator for its end users.

Functions

The air blast cooler is often utilized as hydraulic oil cooler, engine oil cooler and coolant cooler in engineering vehicles, construction machines, vehicles, generator sets, and air compressors. It can also be installed in wind turbines, railway vehicles and marine engines.

Project Cases

Backed by our 20 years’ experience in this industry, we have successfully designed air blast coolers for Caterpillar cranes, Komatsu excavators, and Cummins gensets.

Drive

1. DC24V or DC 12V electric motor

2. AC220V, AC110V, or AC380V electric motor

3. Hydraulic motor

Working Conditions

1. Fluids that do not corrode the aluminum

2. Design Pressure: 1.6MPa

3. Cooling system maximum working pressure: ≤2.0MPa

4. Maximum working temperature: ≤200°C

5. Breakdown pressure: 5.3MPa

Other Parts

Upon your request, we can add a temperature controller, oil filter, electrical relay, or a bypass valve to our air cooled radiator.

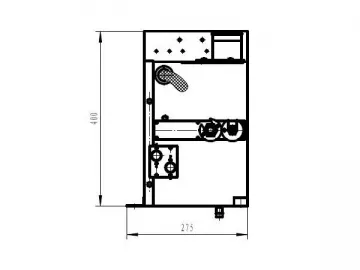

| Model | Outside Dimension (L×W×T) | Mounting Method | Fan Drive | Heat Dissipation (m²) | Oil Inlet and outlet Specification | Matching Vehicle Model | Dimensional Drawing |

| FLJ-4B | 585×405×235 mm | Mounting Block 4-M10 | DC2.4 Condenser | 11.2 | 2-Φ30 | 37m truck-mounted concrete pump | |

| FLJ-12F | 865×806×447 mm | Mounting Block8-Φ11 | Hydraulic Motor | 45.64 | 2-Φ48 | 12-20T*m rotary drilling rig | |

| FLJ-19 | 765×542×490 mm | Mounting Block 6-14×20 | 380V 370W AC Electric Motor | 21.98 | 2-Φ48 | 60m trailer-mounted concrete pump | |

| FLJ-20 | 705×522×310 mm | Mounting Block 4-Φ12 | 380V 370W Electric Motor | 24.22 | 2-Φ30 | 60m trailer-mounted concrete pump | |

| FLJ-25 | 641×474×260 mm | Mounting Plate 8-10×16 | DC.24V Condenser | 16.48 | 2-G1 ¼ | 25-52T Wheel-mounted crane | |

| FLJ-28A | 1200×880×390mm | Mounting Plate 6-14×18 | Not Available | 113.7 | 2-Φ42 | Rotary Drilling Rig | |

| FLJ-28B | 1200×900×500 mm | Mounting Plate 6-14×18 | Hydraulic Motor | 113.7 | 2-Φ42 | 600T Crawler Crane | |

| FLJ-37 | 770×540×235 mm | Mounting Bracket 6-14×20 | 380V 370W Hydraulic Press | 23.14 | M48×2-6H | 60m Trailer-Mounted Concrete Pump | |

| FLJ-39 | 670×400×318 mm | Mounting Bracket 4-Φ21 | DC.24V Condenser | 9.95 m² | 2-φ54 (inside diameterφ30) | 16T-25T crane | |

| FLJ-49 | 610×550×261 mm | Mounting Plate 4-12×16 | DC.24V Condenser | 21.65 | 2-Φ30 | 70T-100T crawler crane | |

| FLJ-69 | 600×580×283 mm | Mounting Bracket with Threaded Holes (4-M10) | DC.24V Electric Motor | 24.8 | 2-φ30 Flange | ---- | |

| FLJ-74 | 600×465×200 mm | Female Thread 2-G1 | DC 24V Condenser | 11 | --- | --- |

The above specifications are provided for your reference only. We can design and manufacture products according to your specific requirements.

Links:https://globefindpro.com/products/44606.html

-

Vertical Scrap Baling Press

Vertical Scrap Baling Press

-

Wall Saw Blade

Wall Saw Blade

-

Vertical Baler for Paper, Plastic and Straw

Vertical Baler for Paper, Plastic and Straw

-

LFB Laser-Welded Diamond Blade

LFB Laser-Welded Diamond Blade

-

Turbo Diamond Cup Wheel

Turbo Diamond Cup Wheel

-

LTA Laser-Welded Turbo Segmented Diamond Blade

LTA Laser-Welded Turbo Segmented Diamond Blade

-

Air conditioner for Excavator

Air conditioner for Excavator

-

Heavy Duty Scrap Shear

Heavy Duty Scrap Shear

-

Semi Automatic Horizontal Baler

Semi Automatic Horizontal Baler

-

Automatic Horizontal Baler

Automatic Horizontal Baler

-

Air Conditioner for Crane

Air Conditioner for Crane

-

Aluminium-Plastic Riveted Water Tank

Aluminium-Plastic Riveted Water Tank