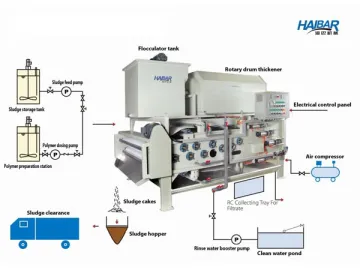

HTA Belt Filter Press Combined Rotary Drum Thickener, Economical Type

Widely used in a variety of industries, the belt filter press carries out a combined thickening and dewatering process and is an integrated device for sludge and waste water treatment.

HAIBAR's belt filter press is 100% in-house designed and manufactured, featuring a compact structure in order to treat different types and capacities of sludge and wastewater. Our products are well-known throughout the industry for their excellent performance, as well as their efficiency, low energy consumption, low polymer consumption, cost saving performance and long service life.

An HTA Series belt filter press is an economical belt press known for the rotary drum thickening technology.

Features

Integrated rotary drum thickening and dewatering treatment processes

Wide range of economical applications

The best performance is found when the inlet consistency is 1.5-2.5%.

Installation is easy due to the compact structure and small size.

Automatic, continuous, stable and safe operation

Environmentally friendly operation is due to the low energy consumption and low noise levels.

Easy maintenance assists in the long service life.

The patented flocculation system reduces polymer consumption.

The spring tension device is durable and features a long service life with no need for maintenance.

5 to 7 segmented press rollers support different treatment capacities with the matched best treatment effect.

Main Specifications

| Model | HTA-500 | HTA-750 | HTA-1000 | HTA-1250 | HTA-1500 | HTA-1500L | |

| Belt Width (mm) | 500 | 750 | 1000 | 1250 | 1500 | 1500 | |

| Treating Capacity (m3/hr) | 1.9~3.9 | 2.9~5.5 | 3.8~7.6 | 5.2~10.5 | 6.6~12.6 | 9.0~17.0 | |

| Dried Sludge (kg/hr) | 30~50 | 45~75 | 63~105 | 83~143 | 105~173 | 143~233 | |

| Water Content Rate (%) | 66~84 | ||||||

| Max. Pneumatic Pressure (bar) | 3 | ||||||

| Min. Rinse Water Pressure (bar) | 4 | ||||||

| Power Consumption (kW) | 0.75 | 0.75 | 0.75 | 1.15 | 1.5 | 1.5 | |

| Dimensions (Reference) (mm) | Length | 2200 | 2200 | 2200 | 2200 | 2560 | 2900 |

| Width | 1050 | 1300 | 1550 | 1800 | 2050 | 2130 | |

| Height | 2150 | 2150 | 2200 | 2250 | 2250 | 2600 | |

| Reference Weight (kg) | 760 | 890 | 1160 | 1450 | 1960 | 2150 | |

Note

1. Our company reserves the right to change the design of the above-mentioned specifications.

2. The treating capacity, dried sludge, and water content rate are determined by the varieties of sludge.

Customer case

Links:https://globefindpro.com/products/44986.html

-

Dream Sky Series Playground

Dream Sky Series Playground

-

Semi-auto PET Film Rewinder

Semi-auto PET Film Rewinder

-

Auxiliary Equipment for Belt Filter Press (BFP)

Auxiliary Equipment for Belt Filter Press (BFP)

-

Stretch Wrapping Machine

Stretch Wrapping Machine

-

HTE Belt Filter Press Combined Rotary Drum Thickener, Heavy Duty Type

HTE Belt Filter Press Combined Rotary Drum Thickener, Heavy Duty Type

-

HPL2 Series Two Tank Continuous Polymer Preparation System

HPL2 Series Two Tank Continuous Polymer Preparation System

-

HTB Belt Filter Press Combined Rotary Drum Thickener, Standard Type

HTB Belt Filter Press Combined Rotary Drum Thickener, Standard Type

-

HTA3 Sludge Filter Press for Sludge Thickening and Dewatering (Gravity Belt Type)

HTA3 Sludge Filter Press for Sludge Thickening and Dewatering (Gravity Belt Type)

-

HPL3 Series Three Tank Continuous Polymer Preparation System

HPL3 Series Three Tank Continuous Polymer Preparation System

-

Metering Systems for Polymers

Metering Systems for Polymers

-

Automatic Film Rewinder

Automatic Film Rewinder

-

Swing Set

Swing Set