HPL3 Series Three Tank Continuous Polymer Preparation System

The HPL3 series continuous polymer preparation system is referred to the 3-chamber continuous flow system for polymer solution preparation. The solution preparation system is formed by three tanks. Separated by the partition panel, these tanks are respectively used for mixing, maturing and storage.

Benefits

1. A combination of three tanks contributes to the continuous preparation process, providing such advantages as easy operation, convenient maintenance, and the great reduction of labor cost.

2. Built to meet the requirements of different flocculants, the continuous polymer preparation system is designed to give the powder-liquid double feed function.

3. By virtue of the proportional allocation function, this continuous polymer preparation system allows the required concentration of the prepared polymer solution to be adjusted arbitrarily in line with the actual requirements on site.

4. Uniform concentration of the solution prepared by the automatic dissolver can reduce the unnecessary maintenance costs and the cost of powder, as the pipeline or pump is gradually blocked resulted from the occurrence of the caking by improper manual allocation.

5. The powder feed tank offers the function of keeping warm and resisting coagulation, which can prevent powder from being caked or going bad due to moisture.

6. The powder feeder comes with the frequency-speed display device, which allows the feed concentration to be controlled more precisely.

7. This mixer has achieved the utility model patent. It features thorough mixing, superior quality, and innovative functions.

8. The continuous polymer preparation system can realize the automatic intermittent mixing operation to mix the solution uniformly. In this way, the optimal condition can be guaranteed whenever the polymer solution is added.

9. A detector can be optionally provided to give the automatic alarm and shutdown function, when the powder feed tank has low storage. It allows the whole machine to be controlled perfectly.

Detailed Picture

Front View of the Control Cabinet

Top Brand Components

Organized inside the Control Cabinet

Heating Equipment Used for Effectively

Preventing the Blockage Caused by

the Caking of Wet Polymer

Screw Conveyor Used for Guaranteeing

the Precise Concentration of the

Prepared Polymer Solution

Links:https://globefindpro.com/products/44983.html

-

HTA3 Sludge Filter Press for Sludge Thickening and Dewatering (Gravity Belt Type)

HTA3 Sludge Filter Press for Sludge Thickening and Dewatering (Gravity Belt Type)

-

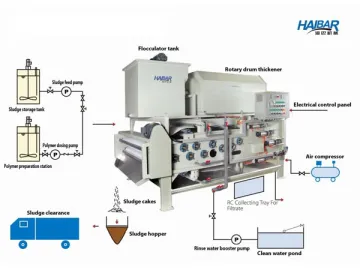

HTB Belt Filter Press Combined Rotary Drum Thickener, Standard Type

HTB Belt Filter Press Combined Rotary Drum Thickener, Standard Type

-

HTA Belt Filter Press Combined Rotary Drum Thickener, Economical Type

HTA Belt Filter Press Combined Rotary Drum Thickener, Economical Type

-

Dream Sky Series Playground

Dream Sky Series Playground

-

Semi-auto PET Film Rewinder

Semi-auto PET Film Rewinder

-

Auxiliary Equipment for Belt Filter Press (BFP)

Auxiliary Equipment for Belt Filter Press (BFP)

-

Metering Systems for Polymers

Metering Systems for Polymers

-

Automatic Film Rewinder

Automatic Film Rewinder

-

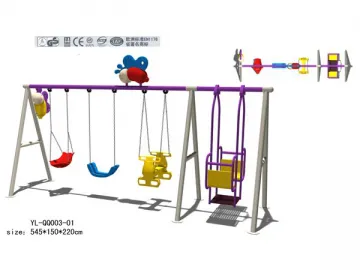

Swing Set

Swing Set

-

HTB3 Industrial Filter Press for Sludge Thickening and Dewatering (Gravity Belt Type)

HTB3 Industrial Filter Press for Sludge Thickening and Dewatering (Gravity Belt Type)

-

Semi-automatic Pre-Stretch Slitter Rewinder

Semi-automatic Pre-Stretch Slitter Rewinder

-

HTE3 Heavy Duty Belt Filter Press for Sludge Thickening and Dewatering (Gravity Belt Type)

HTE3 Heavy Duty Belt Filter Press for Sludge Thickening and Dewatering (Gravity Belt Type)