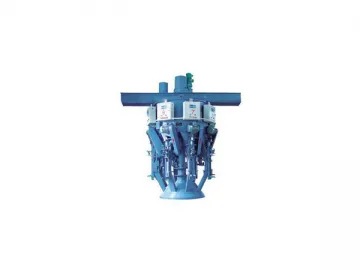

Oxidized Pellet Rotary Kiln

Main components of the oxidized pellet rotary kiln include the rotary part, supporting unit, drive mechanism, kiln hood, sealing mechanism, and the combustion system.

1. The guard board at the kiln mouth and the feed material-recycling unit at the kiln tail are cast individually, so they are convenient for mounting and offer superior resistance to heat, corrosion, and wearing.

2. Cooling air system at the lower kiln end ensures uniform cooling for the shell body and guard plate, providing higher safety and reliability.

3. The kiln hood with large volume design employs a double-leaf wicket structure to make airflow smooth and stable.

4. Both ends adopt a double seal system with simple structure, ensuring convenient maintenance.

5. The combustion system incorporates a spiral-flow type, four-channel pulverized coal burner with an oil injection ignition device.

In addition to rotary kiln, we can also offer many other types of auxiliary equipment for oxidized pellet production, including rotary dryer, disc feeder, disc granulator, chain grate heater, pellet cooler, blender mixer, coal mill, and more.

Technical Specifications| Product name | Size | Capacity (t/h) | Power (kw) |

| Rotary dryer | Φ1.8×14m | 30-40 | 22 |

| Φ2×14m | 40-60 | 22 | |

| Φ2.2×12m | 50-55 | 55 | |

| Φ2.2×16m | 40-45 | 75 | |

| Φ2.4×18m | 45-60 | 95 | |

| Φ3×20m | 160 | 220 | |

| Φ3.6×24m | 150 | 250 | |

| Φ4.2×25m | 250 | 315 | |

| Disc granulating machine | Φ3.6m | 18-20 | 22 |

| Φ4.2m | 28-33 | 55 | |

| Φ4.5m | 35-45 | 75 | |

| Φ5.5m | 40-60 | 110 | |

| Φ6m | 65-70 | 110 | |

| Chain grate heater | 1.6×24m | 100,000-200,000 tons/year | 15 |

| 2.4×24m | 300,000 tons/year | 11 | |

| 2.8×36m | 400,000-600,000 tons/year | 18.5 | |

| 2.8×42m | 400,000-600,000 tons/year | 18.5 | |

| Rotary kiln | Φ2.2×18m | 10-12 | 45 |

| Φ2.5×20m | 18-25 | 30 | |

| Φ2.8×22m | 30-34 | 90 | |

| Φ3×28m | 40 | 90 | |

| Φ3.5×30m | 50 | 220 | |

| Φ4×30m | 90 | 190 | |

| Φ4.7×35m | 140-180 | 315 | |

| Φ5×35m | 165-202 | 315 | |

| Φ6.1×40m | 226-335 | 315 | |

| Pellet cooler | 20m ² | 40 | 7.5×2 |

| 30m ² | 40-60 | 11×2 | |

| 40m ² | 90 | 15×2 | |

| 50m ² | 112 | 15×2 | |

| 69m ² | 130-160 | 11×2 | |

| 121m ² | 270-304 | 15×2 | |

| 128m ² | 280-315 | 18.5×2 | |

| 140m ² | 302 | 11×2 |

Note: Above technical specifications are provided for your reference only. Detailed ones are provided in contracts.

Related Names

Industrial Kiln | Agglomeration Equipment | Tubular Furnace

Links:https://globefindpro.com/products/45312.html

-

Mining Mill

Mining Mill

-

5000 Ton Dry Process Cement Plant

5000 Ton Dry Process Cement Plant

-

Raw Material Mill

Raw Material Mill

-

Lubrication System and Mill Control Cabinet

Lubrication System and Mill Control Cabinet

-

Material Feed Weigher

Material Feed Weigher

-

2500 Ton Dry Process Cement Plant

2500 Ton Dry Process Cement Plant

-

PP/PE Mono-axially Stretching Film Line

PP/PE Mono-axially Stretching Film Line

-

Elevator Conveyor

Elevator Conveyor

-

Edge Recycling Pellet Mill

Edge Recycling Pellet Mill

-

Cement Packaging Machine

Cement Packaging Machine

-

Uniaxial Stretching Lithium-ion Battery Separator Film Extrusion Line

Uniaxial Stretching Lithium-ion Battery Separator Film Extrusion Line

-

Vertical Mill

Vertical Mill