Uniaxial Stretching Lithium-ion Battery Separator Film Extrusion Line

The battery separator film extrusion line is provided to produce the uniaxial stretching lithium-ion battery separator film by adopting the PP or PE as the main raw material mixed with various grades of auxiliary materials. The film production is finished after successively applying tape casting, extrusion molding and uniaxial stretching technologies.

Equipped with high-precision detecting instruments and cooperating with renowned academic institutions in China, we utilize the production technologies developed by us together and mainly produce the uniaxial stretching lithium-ion battery separator film that is 16 to 60μm thick with various specifications. Meanwhile, we also provide customized service.

Features of Our Production Line

1. Through the adoption of the best extrusion system, ultra-thin films with high-precision width and thickness can be efficiently produced by using this production line.

2. It is practicable for universal resins, such as the PP, PE, etc.

Characteristics of Lithium-ion Battery Separator Film

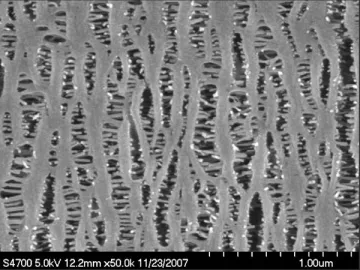

The lithium-ion battery separator film produced by our battery separator extrusion line is a kind of functional polymer material that has nanoscale micropore. The chargeable lithium-ion battery is characterized by high energy density and long cycle life without memory effect. Moreover, it is safe and comes with rapid speed in charging and discharging of electricity.

Conforming to the energy and environment protection demands of all countries, nowadays, the lithium-ion battery is increasingly used in various fields. Hence, the application amount of lithium-ion battery separator film accordingly increases. The detailed characteristics of this film are as follows:

1. The excellent thickness uniformity and evenly distributed micropore are conductive to the consistency of the lithium-ion battery.

2. The micropore has low sinuosity, good air permeability and strong capability of electrolyte retention, and thereby the internal resistance of battery is small.

3. The film is heat resistant without horizontal thermal contraction. As the film breaking temperature is high, it possesses splendid safety performance.

4. The longitudinal tensile strength is high and the mechanical performance is excellent.

5. Generally, the production width of our lithium-ion battery separator extrusion line is within 1000 to 1500mm, while the film with various specifications is also available via consultation by both parties.

Main Applications of Lithium-ion Battery Separator Film

This film is applicable to various lithium-ion batteries that provide power for electric automobiles, motorcycles, bicycles and other electric tools. It is also usable for large energy storage lithium-ion batteries as well as various digital lithium-ion batteries.

Links:https://globefindpro.com/products/45307.html

-

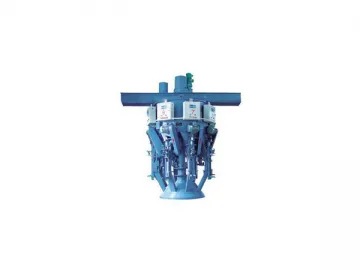

Cement Packaging Machine

Cement Packaging Machine

-

Edge Recycling Pellet Mill

Edge Recycling Pellet Mill

-

Elevator Conveyor

Elevator Conveyor

-

PP/PE Mono-axially Stretching Film Line

PP/PE Mono-axially Stretching Film Line

-

Oxidized Pellet Rotary Kiln

Oxidized Pellet Rotary Kiln

-

Mining Mill

Mining Mill

-

Vertical Mill

Vertical Mill

-

Titanium Dioxide Rotary Kiln

Titanium Dioxide Rotary Kiln

-

Biodegradable PLA/PBAT Cling Film Extrusion Line

Biodegradable PLA/PBAT Cling Film Extrusion Line

-

1000mm Double-layer/Three-layer Co-extruded PE Cast Stretch Film Line

1000mm Double-layer/Three-layer Co-extruded PE Cast Stretch Film Line

-

Rolling Machine

Rolling Machine

-

Cling Film Edge Cutter

Cling Film Edge Cutter