Rotary Die Head Blown Film Line

The rotary die head blown film line mainly works to blow a variety of plastic laminated films made of LDPE, HDPE as well as LLDPE. These PE films are widely employed as raw materials to make packaging bags for liquid, printing substrate, export product, industrial product, and so on.

The barrel and screw of the extruder adopted by the PE film blowing machine are both manufactured from 38CRMOAIA alloy steel with optimum hardness and durability due to the nitrogen treatment and precision finishing. The auxiliary equipment of the blown film line is equipped with platform type working table, making operation more convenient. In addition, it is also equipped with the forming ring. The winding part of the blown film line is characterized by double film winding as well as double cutting blades. The winding operation is driven by the torque motor, thus ensuring appropriate tension, neat roll winding and easy roll changing.

Optional Equipment

1. Automatic Suction Device

2. Surface Treatment Unit

3. Air Compressor

4. Manual Quick Screen Changer

5. Double Film Winding Equipment

6. Rotary Die Head

Technical Parameters

| Model | CP-45HL | CP-50HL | CP-55HL | CP-65HL | ||||||

| Suitable Raw Material | HDPE, LDPE, LLDPE | |||||||||

| Length of Folded Film | 260-600 mm | 300-800mm | 400-1000mm | 600-1300mm | ||||||

| Film Thickness | HDPE | 0.009-0.05mm | 0.009-0.05 mm | 0.009-0.1 mm | 0.009-0.13mm | |||||

| LDPE | 0.02-0.1mm | 0.02-0.1mm | 0.03-0.1mm | 0.03-0.1mm | ||||||

| Max. Extrusion Output | (HDPE) | 50kg /hr | 60kg /hr | 75kg /hr | 90kg /hr | |||||

| (LDPE) | 60kg /hr | 80kg /hr | 95kg /hr | 125kg /hr | ||||||

| Extruding Unit | ||||||||||

| Screw Diameter (mm) | Φ 45 | Φ 50 | Φ 55 | Φ 65 | ||||||

| Screw L/D Ratio | 28:1/ 30:1 | |||||||||

| Plastic Cylinder Material | SACM-645/38 CRMOALA | |||||||||

| Cylinder Cooling | 370W×2 | 370W×2 | 550W×3 | 550W×4 | ||||||

| Temperature Control of Plastic Cylinder | 3 groups | 3 groups | 3 groups | 4 groups | ||||||

| Extruding Motor | 11kW | 18.5kW | 22kW | 37kW | ||||||

| Die Head | ||||||||||

| Extrusion Die Diameter | Φ 60/80 | Φ 60/100 | Φ 100/120 | Φ 120/150 | ||||||

| Temperature Control | 3groups | |||||||||

| Air Ring | 1group | |||||||||

| Central Steady Stick | 2 | |||||||||

| Guiding Unit | 700mm | |||||||||

| Guiding Speed | 10-100m/min | 10-100m/min | 10-100m/min | 10-90m/min | ||||||

| Width of Guiding Roller (mm) | Φ 165×650 | Φ 165×850 | Φ 165×1100 | Φ 165×1400 | ||||||

| Surface Friction Type | ||||||||||

| Winding Diameter | Φ 650mm | |||||||||

| Winding Speed | 10-100m/min | 10-100m/min | 10-100m/min | 10-80m/min | ||||||

| Overall Dimension | 5.0×2.0×4.5m | 5.0×2.2×5.0 m | 5.5×2.5×5.2 m | 5.8×2.8×6.5m | ||||||

Note: The consistent improvement of existing products and development of new functions may make changed the appearance, performance features as well as technical parameters. Customers will not be given relevant notice.

Links:https://globefindpro.com/products/45471.html

-

ZW38-55 Vacuum Circuit Breaker

ZW38-55 Vacuum Circuit Breaker

-

KYN28A-12 Withdrawable Switchgear

KYN28A-12 Withdrawable Switchgear

-

XL21 Distribution Board

XL21 Distribution Board

-

GGD Low Voltage Distribution Switchgear

GGD Low Voltage Distribution Switchgear

-

Co-Extrusion Blown Film Line

Co-Extrusion Blown Film Line

-

MBS Withdrawable Low Voltage Switchgear

MBS Withdrawable Low Voltage Switchgear

-

CW-800SBD ZP Zipper Bag Making Machine

CW-800SBD ZP Zipper Bag Making Machine

-

CW-300V2/ CW-400V2 Vest Carrier Bag Making Machine

CW-300V2/ CW-400V2 Vest Carrier Bag Making Machine

-

CP-500RT, CP-700RT Trash Bag Roll Making Machine

CP-500RT, CP-700RT Trash Bag Roll Making Machine

-

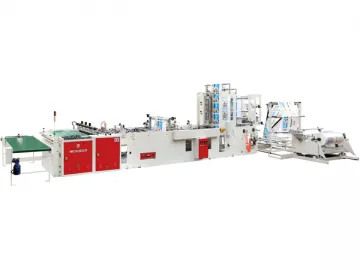

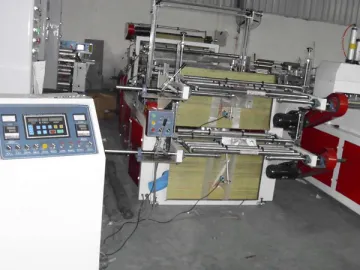

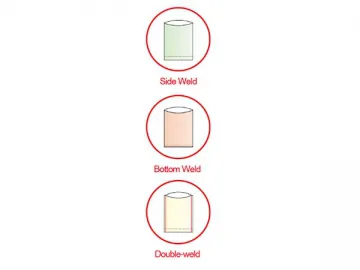

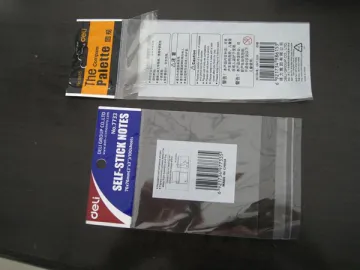

CW-800SBD,CW-1000SBD Side Weld Bag, Bottom Weld Bag Making Machine

CW-800SBD,CW-1000SBD Side Weld Bag, Bottom Weld Bag Making Machine

-

CW-600 BSC, CW-1000 BSC Bottom Weld Bag Making Machine

CW-600 BSC, CW-1000 BSC Bottom Weld Bag Making Machine

-

CP-600RDL, PC-800RDL Side Sealing Plastic Bag Making Machine

CP-600RDL, PC-800RDL Side Sealing Plastic Bag Making Machine