Vacuum Emulsion Mixer

This vacuum emulsion mixer is a perfect combination of the blade-type agitator and the high-shear homogenizer. The blade type agitator gives the function of mixing the high-viscosity huge materials, and the high-shear homogenizer is used for fast mixing tiny materials.

Working Principle

1. There are scrapers around the blade of the agitator. This scraper can be used to effectively remove the adhesive substance from the wall of the pan, for the purpose of fully stirring the substance.

2. The liquid is stirred with the help of our scraper and two sets of mixers in the reverse direction. Next, it needs to go through such processes as shear, compression, folding, and some others. After that, it will flow into the bottom of the container for emulsification.

3. The high-shear dispersing emulsifier serves to efficiently, fast and evenly distribute one or multiple phases to another continuous phase. In most cases, all phases do not dissolve in each other.

4. Generated by the high-speed rotating rotor, the high tangential velocity and high-frequency mechanical effect can produce the forceful kinetic energy. This allows the material between the rotor and the stator to withstand such effects as the strong mechanical and hydraulic shear, centrifugal extrusion, the friction between adjacent liquid layers, as well as the impact-tear and turbulence effect, among others.

Accordingly, the solid phase, liquid phase and gas phase which do not dissolve in each other will be dispersed and emulsified instantly, uniformly and subtly under combined action of mature technology and the right amount of additives. By high-frequency circulating, the high-quality stable product can be eventually obtained.

5. As mentioned above, the combination of homogenizer and blade-type agitator can adequately emulsify and mix the high granularity of materials.

Characteristics

1. With ultra high viscosity of over 50,000cps, the material is recommended to be handled by a corresponding high-viscosity emulsifying homogenizer.

2. Raw materials can be directly inhaled into the tank.

3. This vacuum emulsion mixer offers such functions as pumping, heating and cooling.

4. Emulsification, agitation, dispersion and other processes can be accomplished within a short time.

5. Both low-speed paddle agitation and high-speed homogenization systems come with the frequency control function.

6. Users can select either push-button control or PLC touch panel system.

7. All parts in touch with feed materials are constructed from stainless steel SS316L. This vacuum emulsion mixer is made in full compliance with GMP standards.

8. The stirring process is conducted in the vacuum state, which can effectively guarantee the effect of emulsification.

9. Moreover, our product is equipped with CIP cleaning system, thus providing convenience for cleaning this vacuum emulsion mixer.

Applications

This vacuum emulsion mixer is ideal for use in such industries as food, pharmaceuticals, cosmetics, and chemical materials.

Advantages

1. This machine set puts to use three kinds of mixers on the same shaft. Moreover, our vacuum emulsion mixer adopts hydraulic lifting and descending method to open its cover.

2. The rotational speed of the high-speed homogenizing mixer ranges from 0 to 3500r/min in use of frequency control system. The rotational speed of the low-speed scraper mixer varies from 0 to 40r/min by adopting frequency control system.

4. The homogenizer takes advantage of the high-shear jet type emulsifying mixer. The low-speed scraper mixer is tightly attached to the bottom and wall of the pan.

5. Vacuum is used to inhale the powdered materials to prevent dust from floating in the sky.

6. The whole working procedure is conducted in the vacuum state, which can not only prevent materials from producing bubbles after high-speed agitation, but also meet the requirements for hygiene and asepsis.

7. The internal surface of our vacuum emulsion mixer is subjected to the 300EMSH sanitary grade mirror polishing process, for better guaranteeing the stability of parts.

8. The pushbutton comes from Japan’s Fuji Company. The frequency converter is bought from Japan's Matsushita Electric Industrial Company. The electrical control system is purchased from Siemens Company.

9. This machine set is considered as the most advanced and the most ideal ointment or cream production equipment in China at present.

Technical Parameters

| Model | Effective Capacity | Emulsion Motor | Stirring Motor | Overall Dimension | Total Power | |||||

| kW | r/min | kW | r/min | Length | Width | Height | Overall Height | |||

| DYZRJ-20 | 20 | 2.2 | 0-3500 | 0.37 | 0-40 | 1800 | 1600 | 1850 | 2700 | 5 |

| DYZRJ-50 | 50 | 3 | 0-3500 | 0.75 | 0-40 | 2700 | 2000 | 2015 | 2700 | 7 |

| DYZRJ-100 | 100 | 3 | 0-3500 | 1.5 | 0-40 | 2920 | 2120 | 2200 | 3000 | 10 |

| DYZRJ-150 | 150 | 4 | 0-3500 | 1.5 | 0-40 | 3110 | 2120 | 2200 | 3100 | 11 |

| DYZRJ-200 | 200 | 5.5 | 0-3500 | 1.5 | 0-40 | 3150 | 2200 | 2200 | 3100 | 12 |

| DYZRJ-350 | 350 | 7.5 | 0-3500 | 2.2 | 0-40 | 3650 | 2650 | 2550 | 3600 | 17 |

| DYZRJ-500 | 500 | 7.5 | 0-3500 | 2.2 | 0-40 | 3970 | 2800 | 2700 | 3950 | 19 |

| DYZRJ-750 | 750 | 11 | 0-3500 | 4 | 0-40 | 3780 | 3200 | 3050 | 4380 | 24 |

| DYZRJ-1000 | 1000 | 15 | 0-3500 | 4 | 0-40 | 3900 | 3400 | 3150 | 4550 | 29 |

| DYZRJ-1500 | 1500 | 18.5 | 0-3500 | 7.5 | 0-40 | 4000 | 4100 | 3750 | 5650 | 42 |

| TFZRJ-2000 | 2000 | 22 | 0-3500 | 7.5 | 0-40 | 4850 | 4300 | 3600 | Without lifting | 46 |

Related Names

Powder Blending Machine | Inline Mixer | Vacuum Emulsifier

Links:https://globefindpro.com/products/45890.html

-

BZB-FB-1200 12m Bus Spray Booth

BZB-FB-1200 12m Bus Spray Booth

-

15GN-7M Belt Conveyor Shot Blasting Machine

15GN-7M Belt Conveyor Shot Blasting Machine

-

6100 Prep Station

6100 Prep Station

-

Hot Water Tank

Hot Water Tank

-

Roller Conveyor Steel Square and Bar Shot Blast Machines

Roller Conveyor Steel Square and Bar Shot Blast Machines

-

Top Manway Fermentation Tank

Top Manway Fermentation Tank

-

QG Series Roller Conveyor Steel Pipe Inner/Outer Wall Shot Blasting Machine

QG Series Roller Conveyor Steel Pipe Inner/Outer Wall Shot Blasting Machine

-

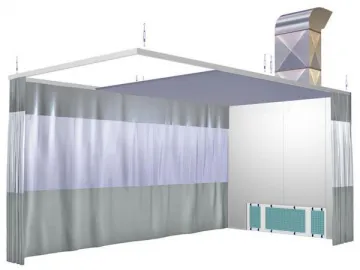

Sand Blasting Room

Sand Blasting Room

-

800A Prep Station

800A Prep Station

-

EPS Panel

EPS Panel

-

Paint Mixing Room

Paint Mixing Room

-

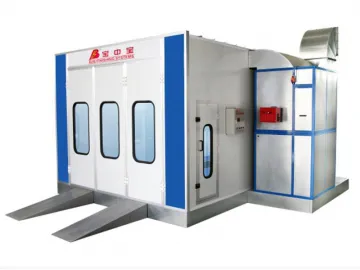

BZB-8200 Car Spray Booth

BZB-8200 Car Spray Booth