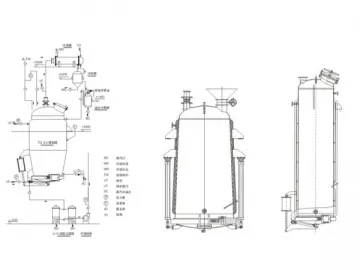

Reactor

This reactor is constructed from stainless steel. It is characterized by rapid heating, high temperature resistance, corrosion resistance, convenient use, no environmental pollution, and the automatic heating function without a boiler, among others.

Applications

Our product can be widely applied in petroleum, rubber, pesticide, dyestuff, pharmaceutical, food, and chemical industries. It serves to accomplish such technical processes as vulcanization, nitration, hydrogenation, alkylation, polymerization, condensation, and some others.

A stirring apparatus is often utilized to fully mix the materials involved in the reaction, especially in such physical processes as heating, cooling, liquid extraction, gas absorption, and more. In addition, we can design and manufacture the outer-coil reactor for our customers.

Structure

Our reactor is mainly composed of the inner container, jacket, agitation equipment, as well as the backup support. Based on the technical needs, it can be provided with the thermal-insulation structure. All parts in touch with raw materials are formed by 304 or 316L grade high-quality stainless steel. They conform to the GMP standards.

1. Inner Container

The inner container is made from such stainless steel materials as SUS304, SUS316L, SUS321, and some others in accordance with the technical requirements. The internal surface has gone through a mirror polishing process. Both cleaning and sterilization in place are available, and the hygiene requirements can be fully satisfied.

2. Jacket

The jacket of our reactor can adopt the SUS304 grade stainless steel, the Q235-B grade carbon steel, and more on basis of the technical needs.

3. Agitation Equipment

The diameter-height ratio is properly designed, and the stirring apparatus can be customized upon request. The shaft seal of the agitator adopts the pressure-proof and hygienic mechanical seals, for the purpose of maintaining the working pressure inside the tank, and also avoiding the unnecessary pollution and material loss resulted from the leakage of materials inside the tank.

4. Backup Support

The support adopts either the suspension lug or the landing leg in compliance with the operational requirements.

5. Fittings

a. The frame type stirrer is often used to make sure that the material can be evenly blended within a short time. Based on the requirements of customers, other types of stirrers are also available, such as the anchor type, and paddle type, among others.

b. Our fast clamp type joint is made in accordance with the ISO standards, thus being convenient and hygienic.

c. Other fittings cover the sterile respirator, CIP cleaning nozzle, sight glass, flange, and the hygienic quick-opening manhole, among others.

Surface Treatment

The internal surface of our reactor is treated with a mirror polishing process to guarantee hygiene and no dead corner. The totally enclosed design makes sure that the material is always aseptic. The treatment methods for the external surface are optional, such as sandblasting, dull polish, and cold-rolled satin finish.

Heating and Cooling

There are various heating methods for option, such as steam heating, electrical heating, and the heat transfer oil. In this way, our reactor can satisfy the technical requirements in different working environments for resisting acids, alkalis, high temperature, abrasion, corrosion, and some others.

Related Names

High Pressure Reactor | Chemical Reactor | Stirred Tank Reactor

Links:https://globefindpro.com/products/45903.html