Magnetic Mixing Tank

| 500L Tank with Jacket | Two 500L Tanks with Jacket | Magnetic Mixing Tank | Inside of Tank |

| CIP Ball | Rotor | 90rpm Per Minute | 480rpm Per Minute |

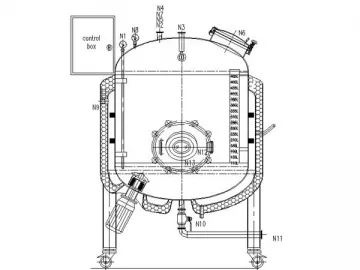

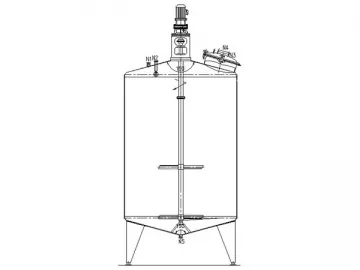

| 960rmp Per Minute | Do Testing | Structural Chart | Structural Chart |

Our magnetic mixing tank has obtained CE certifications, and it is made in compliance with ISO standards. Its production capacity varies from 100L to 25,000L. This all stainless steel product is proper for use in such industries as food, juice, dairy products, bioengineering, and pharmaceutical chemicals, among others. All its parts in touch with feed materials select the sanitary grade stainless steel 304 or stainless steel 316L.

Structure

1. Our magnetic mixing tank features pretty humanized structural design and strong maneuverability. It comes with three optional jackets, including the dimple jacket, coiled-tube jacket, and the overall jacket.

2. Additionally, its insulating layer is formed by PU foam, which features superb thermal-insulation effect.

3. The internal wall of the container adopts the circular-arc transition, thus guaranteeing a hygienic design without dead corners.

4. This magnetic mixing tank is internally mirror-polished, and its roughness average is at most 0.4. In addition, the external surface of the container can optionally receive a brushed finish, satin finish, or 2B finish. We can design and manufacture our goods as per customer requirements.

5. Steam serves to heat the material. Customers are needed to inform us of the steam pressure inside the jacket to select a proper thickness of stainless steel sheets.

6. The mixer motor is derived from selectable brands, such as ABB, SEW, Siemens, as well as the ordinary domestic motors. Its available installation methods include the top mounting, side mounting, and the bottom mounting.

7. The rotational speed during agitation is fixed. Alternatively, it can be regulated by equipping a frequency converter. A control cabinet can be utilized to control the agitation speed on request.

8. The fittings of our magnetic mixing tank comprise the thermometer, sight glass, cleaning ball, pressure gauge, quick-opening manhole, the material-outlet matching butterfly valve, the electronic weighing system, as well as the liquid level gauge and liquid level control system. The last two fittings are installed in line with customer needs.

Related Names

Chemical Mixing Equipment | Industrial Mixer | High Pressure Tank

Links:https://globefindpro.com/products/45949.html

-

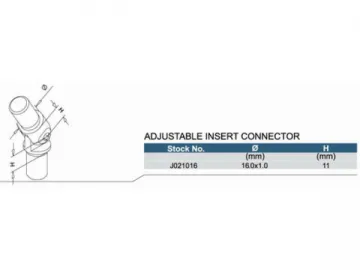

Stainless Steel Adjustable Insert Connector

Stainless Steel Adjustable Insert Connector

-

Stainless Steel Plate

Stainless Steel Plate

-

Stainless Steel Handrail Wall Bracket

Stainless Steel Handrail Wall Bracket

-

Stainless Steel Adjustable Elbow

Stainless Steel Adjustable Elbow

-

Stainless Steel Welded Elbow

Stainless Steel Welded Elbow

-

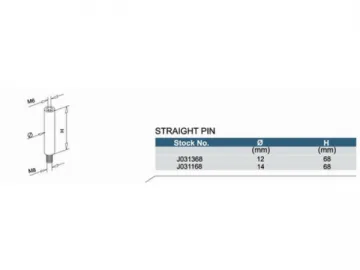

Stainless Steel Straight Pin

Stainless Steel Straight Pin

-

Steam Jacketed Kettle

Steam Jacketed Kettle

-

Single Layer Mixing Tank

Single Layer Mixing Tank

-

Electrical Heating Mixing Tank

Electrical Heating Mixing Tank

-

Plate and Frame Filter

Plate and Frame Filter

-

Cold Liquor Tank

Cold Liquor Tank

-

Milk Weight Tank

Milk Weight Tank