Electrical Heating Mixing Tank

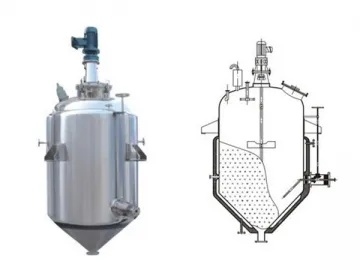

Our electrical heating mixing tank serves to blend or homogenize materials in a wide range of industries including resins, food, coatings, pharmaceuticals, building materials, chemicals, pigments, and scientific research, among others.

With its production capacity range from 100L to 25,000L, this all stainless steel made product has already obtained CE certificates, and it is made in accordance with ISO standards. All its components touching with feed materials are constructed from stainless steel 304 or stainless steel 316L upon request.

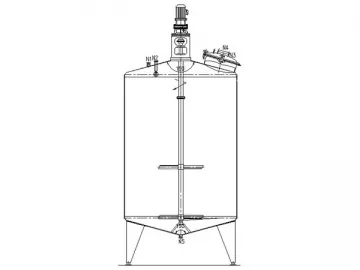

Structure

This electrical heating mixing tank is provided with the overall jacket and the insulating layer. This insulating layer is composed of PU foam, thus featuring superior heat-preservation effect.

Our product is internally subjected to a mirror polishing process, and the roughness average is no more than 0.4. Its outer surface can choose a brushed finish, satin finish, or 2B finish. We can also comply with customer needs to design and manufacture our product.

Heating Method

The bottom of the electrical heating mixing tank is mounted with an electric heater for the purpose of heating materials. Clients are needed to tell us the maximum heating temperature and the heat-up time, so that we can help our customers select the appropriate power of electric heating tube.

If the heating temperature is lower than 100 degrees Celsius, the jacket can use water as its heating medium. The water inside the jacket is heated by the electric heating tube, which can indirectly heat the material inside the container. If the required heating temperature is higher than 100 degrees Celsius, the jacket can choose the heat transfer oil for heating.

Mixing Type

1. The available agitation patterns of our electrical heating mixing tank include the propeller type, paddle type, frame type, anchor type, magnetic stirring type, high-shear emulsification type, ribbon type, turbo type, and hinge type, among others.

2. Different brands of mixer motor can be offered, such as ABB, SEW, Siemens, and the ordinary domestic motor.

3. The installation methods of the mixer motor include the top mounting type, side mounting type, and the bottom mounting type.

4. The speed of agitator can be either fixed or regulated by assembling a frequency converter.

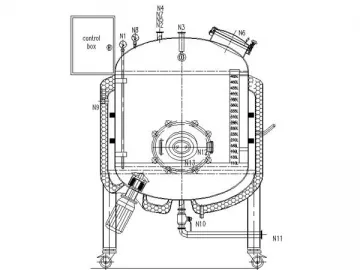

5. A control cabinet is used to control the heating of electric heating tube. The bottom of the container is equipped with a digital thermometer. Customers can set the heating temperature within the control cabinet.

Fittings

There are eight different fittings inside our electrical heating mixing tank, including the quick-opening manhole, sight glass, cleaning ball, digital thermometer, pressure gauge, the material-outlet matching butterfly valve, the electronic weighing system, as well as the liquid level gauge and liquid level control system. The last two fittings are mounted as per customer requirements.

Related Names

Industrial Blender | Pressure Vessel | Fluid Stirring Tank

Links:https://globefindpro.com/products/45946.html