Industrial Cable Manufacturer

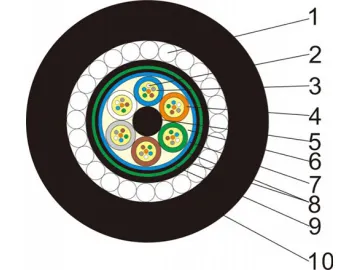

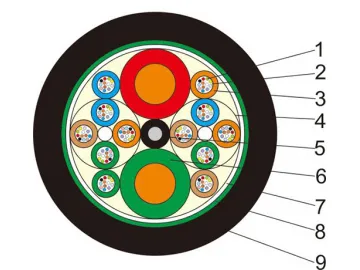

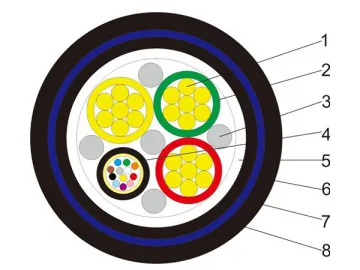

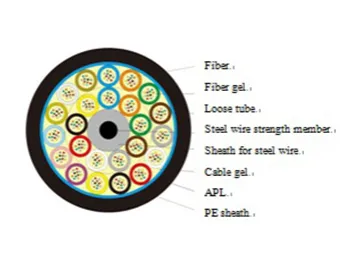

The cable features an insert of single-mode or multi-mode into loose tube made of high modulus polyester material and filled with water proof compounds. The center of cable core is a metallic strength core. For the cables with a certain number of cores, the metallic strength core sheathed with polyethylene (PE). The loose tube (and filling rope) is twisted around the central strength core to form a compact circular core, whose cracks are filled with water blocking materials. Extruded polyethylene sheath is inserted into cable after the double chromium-plated plastic steel tape is vertically wrapped. Finally, an extruded polyethylene sheath into cable after armored of single steel wire.

The stranded loose tube single steel wire armored cable is suitable for Long distance and interoffice communication.

Parameter 1. Technical parameter| Item | Content | Value | ||||||

| Number of cable cores | 24 | 36 | 48 | 72 | 96 | 120 | 144 | |

| Loose tube | Outer diameter | 1.8 | 2.5 | 2.5 | 2.5 | 2.5 | 2.5 | 2.5 |

| Number of Loose Tube* number of cores per tube | 4*6 | 6*6 | 4*12 | 6*12 | 8*12 | 10*12 | 12*12 | |

| Reference outer diameter | mm | 18.5 | 18.5 | 20.0 | 21.0 | 22.5 | 24.5 | 26.0 |

| Center strength member | Steel wire | Steel wire | ||||||

| Water blocking material | Water blocking cable gel | Water blocking cable gel | ||||||

| Damp-proof layer | / | / | ||||||

| Armored layer | Corrugated aluminium belt | Corrugated aluminium belt | ||||||

| Inner sheath | 1.0 | 1.0 | ||||||

| Armored layer | Corrugated steel belt | Corrugated steel belt | ||||||

| Inner sheath | 1.0 | 1.0 | ||||||

| Armored layer | Single galvanized steel wire | Single galvanized steel wire | ||||||

| Outer sheath | Thickness0.2mm | 1.8 | ||||||

| Range of operating temperature | -40- +70 | |||||||

| Pull | short-term /long-term(N) | 8000/2000 | ||||||

| Flatten | 6000/3000 | |||||||

| *According to customers requirements, the stranded loose tube armored cable can customize other structures or cores. | ||||||||

2. Characteristic of optical fiber

| G.652.D | G.655 | 50/125m | 62.5/125m | ||

| Attenuation | @850nm | - | - | 3.0dB/km | 3.0dB/km |

| @1300nm | - | - | 1.0dB/km | 1.0dB/km | |

| @1310nm | 0.36dB/km | 0.36dB/km | - | - | |

| @1550nm | 0.22dB/km | 0.23dB/km | - | - | |

| Band width | @850nm | - | - | 500MHzkm | 200MHzkm |

| @1300nm | - | - | 1000MHzkm | 600MHzkm | |

| Fiber cutoff wavelength | 1260nm | 1260nm | - | - | |

| Polarization Mode Dispersion | Single optical fiber | 0.20ps/km | 0.20ps/km | - | - |

| Link valueM=20Q=0.01% | 0.10ps/km | 0.10ps/km | - | - | |

| Item | Inspection standard | Specified value | Requirements |

| Pull | IEC 60794-1-2-E1 | According to technical parameter | Additional attenuation for short term:0.1dB |

| Flatten | IEC 60794-1-2-E3 | According to technical parameter | Additional attenuation for short term0.1dB |

| Impact | IEC 60794-1-2-E4 | The height is 1 meter punch hammer 450g at least 50 times | Residual additional attenuation:0.03dB |

| Backward and forward bending | IEC 60794-1-2-E6 | Loading 150N 30times | Residual additional attenuation:0.03dB |

| Twisting | IEC 60794-1-2-E7 | 1meter 180 10 times | Residual additional attenuation:0.03dB |

| Temperature recycle test | IEC 60794-1-2-F1 | -40 +70 | Change of additional attenuation:0.05dB/km |

| * The monitoring of all optical fiber attenuations change is operated in wavelength of 1550nm. | |||

We control the optical fiber's surplus length accurately to ensure the capability of resisting tension and temperature characteristics.

The material of loose tube has good hydrolysis - resistant performance and high strength. The tube is filled with special ointment to make key protection for optical fiber.

The polyethylene sheath features good anti ultraviolet radiation performance.

We use the following measures to ensure outstanding water blocking performance.Fill the loose tube with special compound

100% cable core filled

PSP enhancing moisture-proof

Installation

Duct, Aerial, Directly buried

Links:https://globefindpro.com/products/50043.html

-

Industrial Cable Manufacturer

Industrial Cable Manufacturer

-

Industrial Cable Manufacturer

Industrial Cable Manufacturer

-

Industrial Cable Manufacturer

Industrial Cable Manufacturer

-

Shower Arm

Shower Arm

-

Shower Column (Bar Shower)

Shower Column (Bar Shower)

-

Hand Shower

Hand Shower

-

Industrial Cable Manufacturer

Industrial Cable Manufacturer

-

Industrial Cable Manufacturer

Industrial Cable Manufacturer

-

Industrial Cable Manufacturer

Industrial Cable Manufacturer

-

Industrial Cable Manufacturer

Industrial Cable Manufacturer

-

Industrial Cable Manufacturer

Industrial Cable Manufacturer

-

Industrial Cable Manufacturer

Industrial Cable Manufacturer