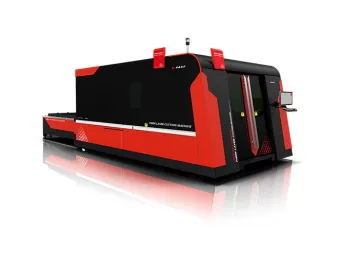

Shuttle Platform Fiber Laser Cutter FCCD

Fiber laser cutting machine can form a very precise laser beam focus on the metal surface, which can achieve high-precision cutting on the premise of ensuring efficiency. Therefore, for precision parts production, automobile manufacturing, lamp processing and other industries, fiber laser cutting is a very ideal processing method.

Many laser equipment manufacturers may tell you about the benefits of a high-power machine, but in fact the power that matches your needs is the best. If you usually process the thinner workpiece, then the medium power fiber laser cutting machine is suitable for you. We can provide 1000W, 1500W 2000W fiber laser cutting machines. They can not only fully meet your processing needs, but also can save cost. For example, it can easily cut 6mm thick stainless steel plate and 5mm thick carbon steel plate and ensure that the cutting section is smooth, so there is almost no need for subsequent processing.

Application

Home appliances Kitchenware Advertising signs Automotive decoration Precision parts Display equipment Hardware products Electric power Automotive manufacturing Sheet metal production and other industries

Materials

Stainless steel Carbon steel Galvanized plate Electrolytic plate Brass plate Aluminum plate Manganese steel Various alloy plate Rare metal, etc. Laser Cutting Photo Gallery

6mm aluminum plate

25mm aluminum plate

18mm carbon steel plate 25mm carbon steel plate

21mm brass plate 25mm brass plate

Note: if you need to cut metal pipes, choose the pipe cutting function. This feature is optional on all our laser cutter models.

Advantages Open structure, so that the operator can directly see the cutting process. Equipped with automatic interchange table, so that the operator does not need to delay precious working time for repeated loading and unloading work. Fiber laser cutting machines work in enclosed spaces to prevent dust and eliminate light pollution. This machine can be equipped with pipe cutting system to complete the cutting of various metal pipes. You can learn more here:

Technical Parameters

| Power | 1000W | 1500W | 2000W | |

| Maximum power consumption | 13kW | 15kW | 18kW | |

| Demand for electricity | 380V,50Hz/60Hz,60A | |||

| Repeated positioning accuracy | ±0.02mm | |||

| Cutting table | 1500×3000mm²,1500×4000mm² | |||

| Flooarear | Take 1500*3000mm shuttle table as an example, its floor space is generally 4700*5000mm, which can also be customized | |||

| Cutting speed | depends on the type and thickness of the material | |||

Cutting Capability Maximum cutting thickness

| Materials | 1000W | 1500W | 2000W |

| Stainless steel | 6mm | 8mm | 10mm |

| Carbon steel | 12mm | 16mm | 16mm |

| Brass | 4mm | 5mm | 8mm |

| Galvanized sheet | 3mm | 3mm | 4mm |

| Aluminum | 4mm | 6mm | 8mm |

Machine structure

This series of medium power fiber laser cutting machine adopts open structure, which is convenient for operators to observe the cutting situation directly and daily maintenance.

In addition, the machine tool body is treated by annealing of CNC electric furnace, improving the rigidity and increasing the precision of the machine structure.

The coating of machine tool body surface is hand-brushed. The hand-brush coating can make the service life of machine body extend 20 years at least. At the same time, this series of laser cutting machines also have automatic interchangeable table, which makes transporting materials more convenient, help to improve work efficiency and productivity.

Fiber laser sourceAll fiber lasers of DNE medium power laser cutting machines adopt IPG brand.

The IPG brand, the world's largest manufacturer of fiber lasers, offers 30 percent electro-optical conversion efficiency. And the service life of the semiconductor pump source can reach 100,000 hours, which means customers don't need to replace it at all.

Laser cutting headThe laser emits only the original beam, which must be focused by a lens with a cutting head to get a laser beam with high enough energy density.

For thinner sheet metal cutting, the short-focus lens works well and does not require high output power support. At the same time, the laser head is equipped with a tracking system with high sensitivity, which can maintain the cutting head and spacing in a very stable state, and can be combined with a short focal lens to enable the laser head to complete the smooth cutting of complex graphics.

Touch screenCombined with the technology of Swiss Bystronic and our own strong optical development capabilities, we develop and design an intelligent touch screen control system so that the operation interface is more simple, convenient, flexible.

Optional Configuration

Side-hanging pipe-cutting table: this equipment can cut up to 3 meters of pipe material. The pipe-cutting equipment is attached to the structure where the machine tool is connected with the cross-beam and there is no other support in the middle. The pipe can be rotated unilaterally with the cutting direction. Floor-standing pipe-cutting table: this device can cut up to 6 meters of pipe material. Compared with the side-hanging pipe-cutting table, the middle of the pipe cutting table is provided with automatic support, and an additional guide rail and a driving motor are installed. The guide rail can automatically transfer materials, and the drive motor can realize completely synchronous rotation with cutting direction. Centering clamping can be done manually or automatically.

Links:https://globefindpro.com/products/51128.html

-

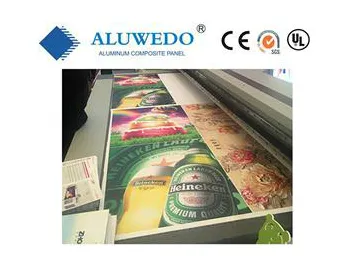

Digital UV Printing Aluminum Composite Panel, ACP Panel

Digital UV Printing Aluminum Composite Panel, ACP Panel

-

1000W FCCDX Medium Power Fiber Laser Cutting System Metal Cutting Machine

1000W FCCDX Medium Power Fiber Laser Cutting System Metal Cutting Machine

-

750W FCCDX Medium Power Fiber Laser Cutting System Metal Cutting Machine

750W FCCDX Medium Power Fiber Laser Cutting System Metal Cutting Machine

-

1500W FCCBDX Medium Power Fiber Laser Cutting System Metal Cutting Machine

1500W FCCBDX Medium Power Fiber Laser Cutting System Metal Cutting Machine

-

1000W FCCX Medium Power Fiber Laser Cutting System Metal Cutting Machine

1000W FCCX Medium Power Fiber Laser Cutting System Metal Cutting Machine

-

3000W High Power Fiber Laser Cutting System Metal Cutting Machine

3000W High Power Fiber Laser Cutting System Metal Cutting Machine

-

750W FCCBDX Medium Power Fiber Laser Cutting System Metal Cutting Machine

750W FCCBDX Medium Power Fiber Laser Cutting System Metal Cutting Machine

-

1000W FCCB Medium Power Fiber Laser Cutting System Metal Cutting Machine

1000W FCCB Medium Power Fiber Laser Cutting System Metal Cutting Machine

-

6000W High Power Fiber Laser Cutting System Metal Cutting Machine

6000W High Power Fiber Laser Cutting System Metal Cutting Machine

-

750W FCCX Medium Power Fiber Laser Cutting System Metal Cutting Machine

750W FCCX Medium Power Fiber Laser Cutting System Metal Cutting Machine

-

Full Cover Fiber Laser Cutter FCCBDX

Full Cover Fiber Laser Cutter FCCBDX

-

EVE Finish Aluminum Composite Panel, ACP Panel

EVE Finish Aluminum Composite Panel, ACP Panel